Forced action concrete mixer - manufacturer do it yourself Instruments

In the process of construction and finishing works, it is impossible to avoid the procedure for the preparation of all kinds of solutions. That is why for the rational organization of the entire process and saving time and money, it will not be superfluous to use special equipment for mixing various components. The optimal solution will be a forced concrete mixer, whose characteristics provide not only effective performance, but also a rather high level of personal safety. How to properly make such a device with your own hands, you will learn from this article.

Content

Concrete mixer forced action - scope

The concrete mixer assembled with their own hands will allow a number of works exactly on time and in the desired volume. You can use it in the following steps:

- for the preparation of directly concrete of various brands;

- for mixing refractory solutions when making a fireplace or furnace;

- in the manufacture of finishing and adhesive mixtures - plaster, cement.

Important! As you have already been convinced, such equipment will need at all stages of construction and arrangement of the landscape zone. If you acquire a device in the store, it will cost it quite expensive. Even if there is enough long-term use in personal needs of one object, it will not pay off. It is also not always possible to rent. And at the same time, make a compulsory mixer can be very cheap with its hands from handy.

Forced concrete mixer - advantages

To evaluate how valid is this device, it is enough to familiarize yourself with the benefits of mixing equipment of this type:

- impeccable quality of mixing individual components, even with very complex combinations and materials of various structures;

- maximum rapid formation of a good solution of the desired consistency;

- the ability to choose the appropriate version of the device;

- high degree of safety during operation;

- excluded a solution of the solution due to the constant flowing of a mixture of pear with proper equipment;

- long period of operation, provided with protective rubber scrapers with blades;

- minimum time and personal service costs;

- the possibility of system functioning even in difficult conditions for the construction site.

Device forced concrete mixer

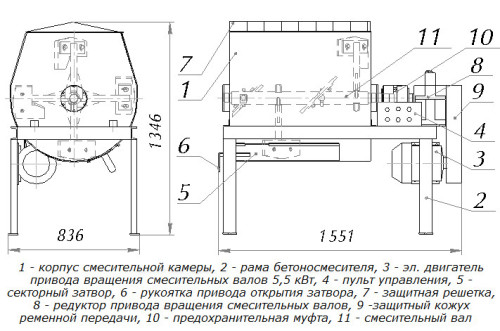

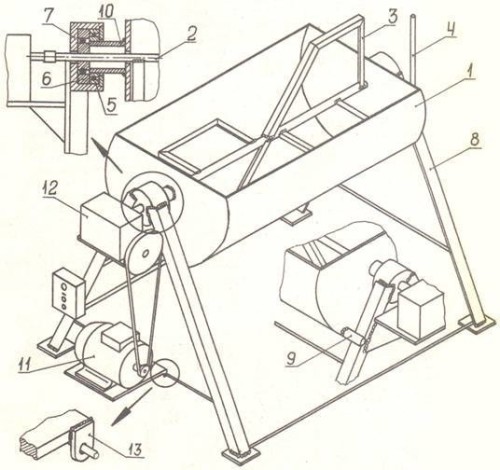

Complete set of concrete mixer of forced action. Standard consists of:

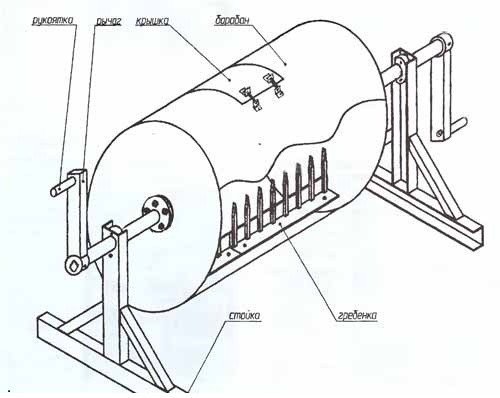

- pears of conical or cylindrical shapes - directly tanks for the preparation of solutions;

- still drum-axis and shaft for blades;

- blades - for wrapping the mixture;

- luke or cover on the tank - to prevent the solution to prevent the solution in the process of wrapping and increasing the drying time of the unused solution;

- electric motor, at the expense of which the blades turns.

Important! The principle of operation of such equipment is quite simple - all the necessary components of the building solution are loaded into the pear. After connecting the concrete mixer to the power grid and turn on the "Start" button, there is a uniform movement of the blades, due to which it is carried out. You can more clearly imagine the design of such a concrete mixer due to the appended photo scheme below.

Tools and materials for concrete mixer do it yourself

The scheme of the concrete mixer is already clear to you, now we will define the materials and tools that will be required to build the equipment with your own hands.

Details:

- The electric motor is suitable from any used machine in suitable condition, the speed of rotation of which will be at least 1500 rpm at a rated power of 220 kW.

- The container for the solution is an excellent option will be the metal or plastic barrel or tank of a suitable volume, for example, 100-200 liters.

- The blades are easy to cut it with a metal with a solid steel sheet or residues after the construction of structures from such a material, and you can proceed easier and make the usual crossbar of the metal rod either pipe.

- Drive shaft. For its manufacture, take a metal rod either pipe.

- Bearings.

- Fastening details - trimming of reinforcement, chawliers, steel corners.

Also take care of the fact that all the necessary tools are in stock so that in an unexpected point, the process of assembling its own mixer for the solution has not stopped. Focus on the following list:

Build technology

The whole process of creating a compulsory concrete mixer does not take a long time in the presence of certain skills to perform such works.

Progress:

- Swelling the holes of the appropriate section from two sides of the case - in the bottom and lid.

- Cut the rectangular hole on the side with parameters 30 * 25 cm - for the hatch.

- Plug the edge of the hatch with a soft rubber profile.

- Screw the hatch cover to the barrel using the bolts + hinges or card loops or metal corners + tie bolts.

- Make a crusade of a metal rod either pipe or take the finished suitable size.

- Install the cross in the barrel inside.

- Fasten with challers and corners using the welding method.

Important! Determining the desired arrangement of hardware in the process of welding, note that it is better to make an indentation of the housing by 1-2 cm to ensure the highest quality and uniform mixing of the solution.

- Welcome together 2 triangles from the corners, making the jumper in the middle.

- Welcome 2 trimming corner near the shaft holes.

- The triangles prepared before it are welded.

Important! 3 Recent Actions to create a supporting design for a concrete mixer will allow maximum stability of the case and its still during vibration during mixing.

- To the racks weld the semiring, which will become handle holders.

- Insert the handle into the prepared holes of the housing through the crossbar inside - this is enough to make mixing manually.

- Install and plug the engine to the shaft if you create an automated unit.

Important! Check out the video below. This will look like and functioning a concrete mixer created by this instruction.

Video

See also the proposed video examples of what can be homemade forced concrete mixer. Choose the most suitable option and make it with your own hands.

Conclusion

As you were convinced, there is nothing particularly difficult in the assembly of the concrete mixer with their own hands. The main thing is to clearly determine the dimensions of the equipment you need, take durable parts for this and correctly assemble the design. You will definitely appreciate the benefit of such a solution throughout the construction of your own home.