Planer for aerated concrete Instruments

In the process of laying aerated concrete blocks, it is often necessary to "fit" individual elements with the help of a special ruble. But often the necessary tool does not turn out to be at hand. This article will provide useful tips on how to make a planer for aerated concrete.

Content

Some information about aerated concrete blocks

In order to properly make a tool for processing the material, it is necessary first to get acquainted with the properties of the latter. The main ones are the following.

- The composition of aerated concrete blocks includes cement, sand, lime, plaster and slags. Gas pores are created using aluminum paste. Due to the porous structure and significant amount of lime in the composition, aerated concrete is possible to be treated with a pitch.

- The blocks are of different density, which affects the wear of the planer. Aerated strength provided by the cement-sand component.

- Aerated concrete blocks of low density (400 kg / m³) have high brittleness and abrasion, which requires care in handling plane.

About the construction of the planer for aerated concrete

Manufactured industrial or homemade method for planer aerated should provide uniform removal of material without destroying the surface layer. In this regard, the tool must meet the following requirements.

- The height of the cutting elements should be such that a single pass filmed uniform layer of aerated concrete.

- The blades on the housing are fixed vertically into several (usually 5-6) rows. The direction of the cutting edges of the half of the series should be the opposite relative to the other half of the series.

- When choosing a metal for the manufacture of knives, the ruble should take into account the density of the processed aerated concrete. For material, the density of no more than 500 kg / m³ is allowed to use the blades of a saw saw. For a more dense aerated concrete, it is necessary to use carbide metals.

- The case of the Rubank should be durable, and the handle is wide and comfortable for grip.

- To connect the details of the homemade ructation, glue is selected, interacting with heterogeneous materials.

How to choose Electrolake for a housekeeping for a house

If you make a planer with your own hands, you can not choose a tool in a construction store. It can be a conventional wooden planer for aerated concrete. But productivity with its help is low. You can speed up the work using manual electrolyak.

How to choose the most suitable model? It is recommended to pay attention to the following.

- Planing Depth: To process aerated concrete, a minimum value of this characteristic (2 mm) is sufficient. It is important that the scale of the planing depth regulator starts not from scratch, but from negative values.

- Planing width: how it will be greater, the easier it will be high quality work. Preferably, the model with the sole is not already 110 mm.

- The quality of the sole is the ruble: it should be smooth and perfectly smooth.

- Weight: The tool should be light (no more than 3.0 - 3.5 kg), as high power (which is interrelated) from it is not required.

- Power is quite minimal. The planer with a capacity of about 1000 W will cost cheaper.

- The presence of a dust collector: such a detail will get rid of the need to work in the respirator.

- Knives for the electrolabank should be made of solid alloy TST. Blades of such metal are not stupid long.

Note: Sharpening Electrolabank is a complex process available only to specialists with special equipment. It is important that in a set with the tool there was an adaptation for sharpening the knives of electrouruk.

How to make a planer for processing aerated concrete blocks

The following tools and devices will be needed for work:

- a corner machine;

- jigsaws;

- hacksaw;

- hammer;

- sandpaper;

- file;

- line, chisel;

- brush;

- marker or carpentry pencil;

- calipers.

The easiest way to make a planer for aerated concrete with their own self-tapping screws. The sequence of actions is the following.

- With the help of an electric bike and hacksaw drinking a wooden blank with a size of 110 × 400 mm. The thickness of the workpiece is 25 mm.

- Processing chamfer and corners with emery and sandpaper, grind the surface.

- With the help of a ruler and caliper on one side of the workpiece at an equal distance from each other, we make markers and blacks of six parallel longitudinal lines.

- Along every line with a step of 5 mm put the labels.

- Using a screwdriver in each mark at an angle of about 30 ° we screw the screws. At the same time, the slope of each row must be opposite to the directional slope of the self-adjustable sinks. The length of the self-samples is chosen so that they have left no more than 2 mm with the opposite side.

- From the board, cut out the arcuate handle with a length of 350 mm and secure it with self-draws to the workpiece.

IMPORTANT: Painted grater (plans) aerated concrete can be a colorless varnish or white paint. Otherwise, traces will remain on the surface of the blocks.

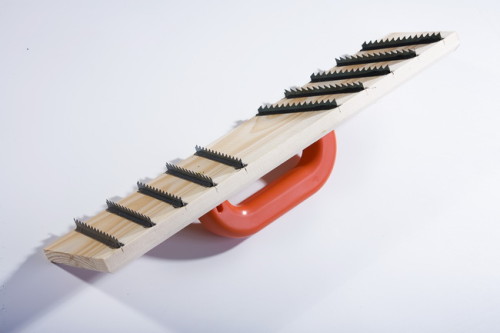

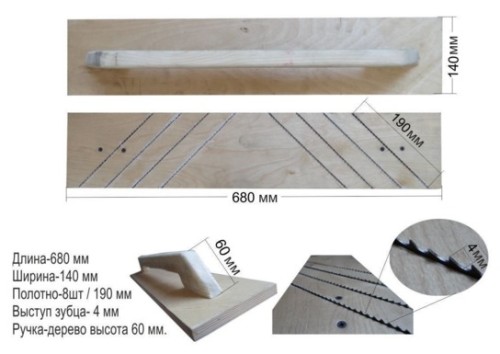

Another way implies the use of pilot for metal for the manufacture of the Blades of the Rubbank. Sequence of action to your attention.

- The billet from the board is placed transverse parallel lines every 6-7 mm.

- According to the lines, the depth of the depth is made equal to half the width of the pylon. In this case, half of the propilov is carried out under the slope in one direction (angle - about 30 °), and the other half is under the tilt in the opposite direction.

- Two-component epoxy glue poured into the propils and peckings are inserted.

- The handle is screwed.

After soaring glue, the plans can be used for its intended purpose.

Additional device for a plane for aerated concrete

In order to make work with a planer easier, a special device is necessary. It is intended to limit the penetration of the Blades of the Rubanka in aerated concrete. The manufacture and use of such a device is as follows.

- Two-stranded and precipulated boards with a thickness of 30 mm are connected to each other with the help of bars that are screwed to the upper edges of the boards. Length of bars is selected equal to the width of the block.

- The device is placed on top of the masonry so that the plane of the bars coincide with the surface of the fason facility.

In conclusion - video with a story about how to make a planer for aerated concrete.