Concrete floor device for soil Floors,Construction

Laying of concrete floor on the ground is a more or less simple embodiment of the classic coating of the floor when building a private household. Often, this type of work is made in homes having a foundation of a ribbon type. In order to equip the concrete floor on the ground there is nothing complicated, it can not only do it, but also a homemade sample.

Content

What is the device of concrete floor on the soil?

Before proceeding with the work, it is necessary to analyze the condition of the soil. It is necessary that it is dry and immobile, and the underground waters climbed at a depth of 5 meters. In addition, keep in mind that this version of the creation of the draft floor is used only for those rooms that are heated during the cold season.

The laying is started when the walls and roof are ready.

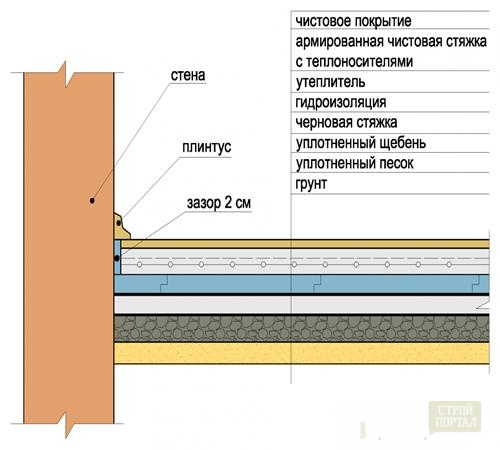

The concrete floor cake on the ground consists of the following layers going upwards:

- The base on which the floor will be arranged - carefully compacted soil.

- Radiation consisting of a layer of sand and a layer of large rubble. Both of them must have a thickness of from 70 to 100 mm. These layers leveled the surface and protect it from a possible lift of groundwater. Subscription, like the previous layer, you need to thoroughly ram.

- A rough screed with a thickness of 50-70 mm, under which the polyethylene film is littered. For this purpose, only river sand and fine crushed stone are used.

- Spray or fill. Polyethylene film in this case does not apply. At this stage, the solution is pouring the layer, in the thickness of an equal black screed.

- Moisture insulation layer of two layers of rubberoid. Use the simplest material without putting up.

- Layer of insulation. The floor laid on the ground is best insulated with EPPS or foam. Pick the thickness, pushing out the characteristics of a particular region.

- The next step is the pure screed with a thickness of 70-100 mm. To do this, shallow crushed stone and river sand applies. This layer requires reinforcement at mandatory. A wire mesh with a diameter of 3-4 mm will be required.

- Now everything is ready for the arrangement of the final coating. Here, the sequence of work will depend on its chosen variety.

What factors affect the sequence of layers and the presence of each of them?

Concrete floor design on soil depends on:

- depths on which underground water;

- equipping the flooring of the floor by the heating system;

- loads that will be exposed to the floor during operation.

Consider each of the listed factors:

- If the distance between the floor and the level of groundwater is less than 2 meters, then the moisture insulating layer of 2 layers of the rubberoid is necessary. In addition to it, it is mandatory for a subference from sand and rubble. In the case when groundwater is deeper than 2 meters from the floor surface, the waterproofing is not needed and the edge too.

Determining the depth of finding an underground source, it should be repeated from its highest point within the region on which construction is conducted.

- If in the future it is planned to equip floating floors, then it is necessary to leave a sufficient gap between the floor and the walls. It is equipped at the finishing screed stage and is necessary for both electrical and heated water floors. In all preceding layers, the clearance is not needed, they adjacent to the walls close.

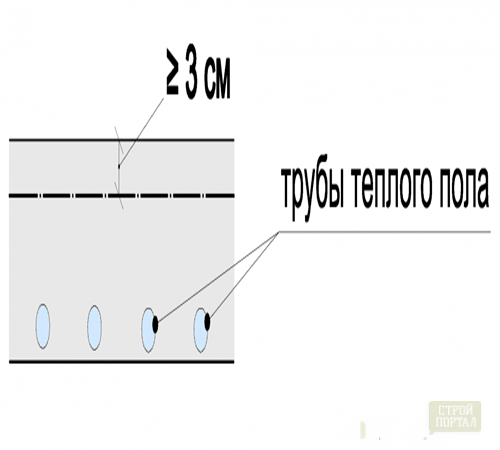

- If it is known in advance that in the process of operation, the floors will be subject to a load greater than 200 kg / sq. M, then it will take reinforcement of a pure screed with a wire with a wire of 4 mm. If the loads are not overlapping for the specified line, you should use a mesh of a fonder wire - 3 mm.

Questions that may arise in the process of work on laying concrete sex on the ground

1. Is it possible to install interior walls on such a floor? Under the condition of the reinforcement of the pure screed, the installation of internal brick walls, partitions from special blocks, walls, thickness of half a clay-concrete, shell, aerated concrete, foam concrete, and other blocks.

2. In what cases when laying a subfolder is allowed to replace the rubble on the ceramzite? In case the recessing is used to protect against water, which can climb the floor level, it is impossible to use clamzite, since He absorbs moisture and swells. But if there are no underground waters and the threat of flooding is absent, and this layer is used to align the surface, then it is allowed to make such a replacement.

3. Is it possible to replace the crushed stone brick or residues of construction waste as partings? Such a replacement is impossible, because these materials are not capable of protecting from the rising water, nor align the surface of the floor.

4. Is it possible to abandon the insulation layer, replacing it with a large number of clay in the layer layer? This should not do, because In order for the replacement to be adequate, the ceramisita will have to pour a very large layer. And such a quantity is impossible to compact well.

5. Is it possible to refuse to reinforce the screed? At the stage of the draft screed, the reinforcement is not necessary, but during purple - it is mandatory.

6. Is the reinforcing mesh replacement for unrelated reinforcement breaks? It is impossible to produce such a replacement.

7. Is it worth putting moisture insulation or insulation on the submission, excluding the draft screed? So it is impossible to do, because if the thermal insulation and moisture insulating layers will not be on a smooth and solid foundation, they will quickly become unsuitable. This will happen due to uneven load distribution. In the case of insulation, the case can end cracks in the floor.

8. Is it possible to replace the draft scuster? If the water level is close close to the floor surface, and the layer of submet plays the role of protection against moisture, then it is impossible to replace the rough screed screed. But if the depth of groundwater occurs exceeds two meters, and the layer of submet simply aligns the surface - such a replacement is possible. If there is no recessing, and the screed is performed on the rammed soil, then it is necessary to make a rough screed, and a spray.

9. Is the polyethylene film under the draft tie replaces the moisture insulation? No, does not replace. The film only prevents the getting of concrete milk into the submetock or soil, but does not perform the function of the main moisture insulating layer.

10. How should the reinforcing mesh be located: from above, below or in the center of the finishing screed? If there is no heating system in the screed, the grid should defend from its surface by about 30 mm - this means closer to the middle. If the heating system is present, the grid must be positioned above the level of the pipes, and on top to provide a protective layer with a thickness of 20-30 mm.

Tips for builders professionals

During work, some advice of professional builders who can significantly help:

1. Exposing the level of concrete floors, take into account the height of all existing doorways, while the markup is made throughout the perimeter of concrete area.

2. To better imagine a marked level, use the stretched cord.

3. Perform all work very carefully and accurately, strictly observing the sequence. Before you start sealing the soil, clean the room from garbage.

4. If the moisture insulation must be strengthened, put the clay layer on the ground, and on it sand. Water clay, thoroughly wrap, then it turns out an insurmountable water barrier.

5. Placeing the concrete floor cake, check each layer horizontally.

6. To improve thermal insulation, use as a supplement foam, isolon, perlite, cork, clayjit, etc.

Concrete floor on the soil - Video: