PPU pipes: description, advantages and disadvantages Building materials

Every year the building market is replenished with a large number of different materials and devices. Thus, the leading position on the market of thermal insulation materials occupy PPU pipes that were specifically designed to minimize the costs of insulation of networks and heat trains by laying an additional layer of polyurethane foam. This material is a universal tool, perfectly retains heat, and therefore it is widely used in different areas of activity.

Content

Even in the seventies of the last century, most developed countries began to widely use steel pipes PPUs (with an insulating layer of polyurethane foam) in order to increase energy savings. And now such technologies have been widely used in Russia.

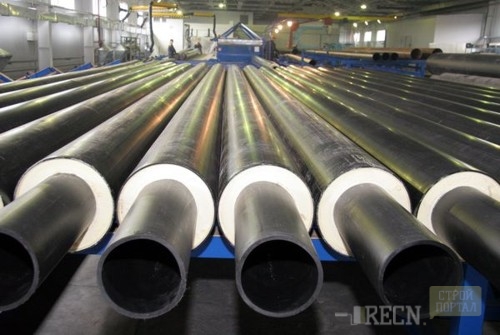

What is PPU pipe

PPU pipe is essentially two pipes embedded in one to another. The pipe manufacturing technology is very simple - first on the ordinary pipe made of steel is applied by a layer of insulation (polyurethane foam - abbreviated PPU), and then the finished pipe is placed in an additional shell consisting of galvanized steel or polyethylene. In addition, the supplement of pipes PPU is the unique development of engineers - a built-in cable that allows remote control and detect problem areas on a specific section of the pipeline. STOK - operational remote control allows you to significantly extend the life of the pipes, as a result of which the risk of heat loss and the likelihood of crimping is reduced.

Each type of PPU pipe is certified according to Gosstandarts (GOST 30732-2006), in accordance with the rules, each pipe is completed by the remote control system (ADC).

Polyurethane foam has a high degree of wear resistance and low thermal conductivity. If we talk about high-quality PPU pipes that meet state standards, the PPU pipes in isolation allow us to transport different liquids on them, including gaseous substances with different pressure (up to sixteen atmospheres) and temperature (maximum - up to fifty degrees Celsius). The heat insulation layer can be both standard and strengthened. This will depend on various factors and weather conditions.

Where PPU pipes are used

Pipes are widely used for laying thermal highways. It is no secret that the heat network has long been worked out due time. Increasingly, especially in large cities, where the load on thermal highways is increased, a large accident rate is observed. As a result, the cost of servicing old heat mains. You can avoid all these problems by completing the full modernization of old housing and utilities systems for new pipes in the polyurethane foam sheath. Such pipes in PPU shell will minimize the cost of heat loss and significantly save funds.

Scope of use of PPU pipes:

- gasket of cold and hot water water supply;

- heat supply (gasket of thermal highways);

- laying of oil and gas pipelines.

Technical characteristics of PPU pipes

PPU insulation pipes are often used to transport heat carriers. Laying pipes in this case is performed by two methods: channel or vagueless.

The main parameters of the coolant:

- working pressure - to one whole tenth of MPa;

- the operating temperature should not exceed one hundred thirty degrees Celsius;

- peak temperature should not exceed the mark of one hundred and fifty degrees Celsius;

- pipes can be laid on the depth of no more than sixty centimeters.

The thickness of the polyurethane foam layer, as well as the walls of the pipe made of steel, can be adjusted depending on the wishes of the customer. It should be borne in mind that the thickness of the pipe walls, as well as the shaped parts should be the same. When purchasing PPU pipes, it is necessary to pay attention to its design - on both sides, each element of the PPU pipe has a free edge without insulating material. The length of such a segment is one hundred and fifty-millimeters, and for each pipe diameter there will be a different length - from DU25 to DU219 - up to one hundred fifty millimeters, pipes from DN 273 to 1020 to two hundred ten millimeters.

What are the advantages and disadvantages of pipes

Despite good thermal conductivity and durability, PPU pipes have both advantages and disadvantages. Consider more in more than the pros and cons of PPU pipes.

Advantages:

- PU's insulation has a low heat conductivity coefficient.

- The temperature of operation can be from minus seventy degrees to plus a hundred thirty degrees Celsius.

- A moderate ability to absorb liquids is noted.

- The material density is fixed by the highest mark.

- The service life without capital repairs is from twenty-five to thirty years.

- Heat losses can be only one or two percent.

- The monitoring system monitors the likelihood of leakage.

- Cash savings.

- The pipe includes everything you need for quick installation - taps, tees, fittings and compensators.

- If compared with other types of thermal insulation materials, the PPU pipes will be easier than similar designs with PPM or APB isolation.

- When using pipes, it is not necessary to carry out additional measures to combat corrosion.

What are the shortcomings of PPU pipes:

- despite the long service life and the presence of operational remote control, PPU pipes are also subject to corrosion. Due to the fact that the metal tube is in a protective shell, the corrosion process becomes not so noticeable;

- the heat resistance of the insulating material does not exceed one hundred and thirty degrees, which does not allow the use of pipes in heating networks operating in different temperature graphs: one hundred forty-seventy and a hundred fifty to seventy degrees. Pipes can withstand such temperature fluctuations under the condition for styling an additional heat insulating layer (for example, a "vector" or polymer concrete);

- polyurethane foam does not differ in high strength and is not resistant to mechanical effects;

- if the moisture is hit by the heat insulating layer, the rapid damage of corrosion pipe is possible. As a result of this factor, exclude the use of additional hydraulic (polyethylene durable layer) - it is impossible;

- if a certain segment of isolation is damaged or moistened, it is necessary to completely replace the heating sector. PPU isolation can not be repaired separately;

- pPU isolation - flammable material;

- each pipeline or heating network must necessarily be equipped with ADC systems to measure the moisture content of the insulating layer.

Installation of PPU pipes

Before starting installation work, it is necessary to conduct preparatory activities. So, before laying the PPU pipe, it is necessary to carefully examine to reveal mechanical damage in advance: cracks, punctures and cuts. If any, they can be filled with welding or impose on a damaged place a heat shrinking cuff.

Next, the pipes in a certain sequence are placed on the edge of the prepared trench with the help of a crane or a pipelayer. Lower the tubes in the trench must be smoothly to exclude the blow. Before laying pipes, it is necessary to check them on the integrity of the ADC system.

You should also take care of the preparation of the trench in advance: it must be smooth, without stones and other acute items. All deepening is desirable to fall asleep with sand.

Such preparatory activities are necessary in order to exclude the wrong installation of PPU pipes, since, according to experts, the third part of the damage to the heat mains occurs due to non-compliance with the laying technology.

Laying pipes PPU is carried out by representatives of contractors. The welding and sealing of the joints of PPU pipes must be performed in good weather at a temperature not lower than zero degrees. If work is performed in bad weather, it is necessary to take care of the additionally installed mobile tents for pipe heating.

As a rule, the pipeline is mounted directly at the bottom of the trench. Live portions of the pipeline can be connected on the heating of the channel using welding. If it is necessary to perform cutting pipes, then this is performed by a special tool - a gas cutter, and insulation of polyurethane foam is pre-removed by manual tools away from the locations of the gas servant. Cropped end It is advisable to cover with a damp cloth or any rigid web.

The infantal portion of the pipeline is connected to the channel using a special device - walls with a seal. When laying a pipeline through the foundation and walls of the buildings, there is a need to apply additional devices - rubber sleeves and lubricants, and only after that the final concreting is performed.

The infantal gasket should be carried out according to pre-prepared drawings, where the load on the local primer and its properties takes place.

PUP laying can be carried out in such ways:

- the infantal method when the pipes immediately fit into the ground;

- reconstruction of the existing heating networks - Laying the sandy semi in the fields of non-passing channels;

- use of sliding supports in channels and tunnels;

- overhead laying method.