Installation of sandwich panels do it yourself Building materials

Sandwich panels are used to build new buildings, as well as for reconstruction and insulation already built.

Content

What is a sandwich panel and where they apply

The panels are released ready or assemble at the installation site.

Sandwich panel element assembly cheaper. It takes a lot more time on their installation than on the installation of ready-made. The only advantage of such panels is that they are small weight and easier to raise them.

Installation rules for element assembly panels are shown in the video.

The finished sandwich panels are made of three main layers, the most sides are tough, there is a heater between them.

For the outer coat, metal, fiberboard, magnesite plates or PVC are used. Fiberglass, expanded fibergistic, mineral wool or polyurethane foam are used as insulation.

The top coating material determines the scope of the panels.

- Metal, galvanized iron - for the roof and construction of frame building structures.

- Fiberboard - for the construction of houses. The coating of fiberboard requires further finishes.

- PVC coating - for decoration trim indoors

With panels having insulation from mineral wool you need to work especially carefully. In violation of the installation rules, moisture penetration is possible inside the panel, this will significantly reduce the service life of the panel as a result of the loss of the properties of thermal insulation. It is necessary to use sealants and overalls for sealing.

More reliable insulation of polyurethane foam. He is not afraid of moisture and retains his qualities for a long time.

The panels of two species are produced - roofing and walls.

Wall panels surface smooth or profiled.

Roofing have a profile from two sides or only with external. The top layer of coating is made of galvanized iron with a thickness of 0.5-0, 7 mm.

Roofing panels differ from the walls of the castle. For the roof, most importantly, the moisture does not get inside.

When buying, learn the technical documentation, it contains recommendations on the installation and requirements for a frame basis.

What tool is used for cutting?

It is impossible to use the grinder - the metal is strongly heated, it leads to the loss of corrosion resistance.

Heaters - mineral wool or polystyrene foams easily flammable. For fire, one spark is sufficient enough, and with a cutting of metal they are formed a lot.

The trimming is performed on the installation site after fixing the panel.

What are the seizures

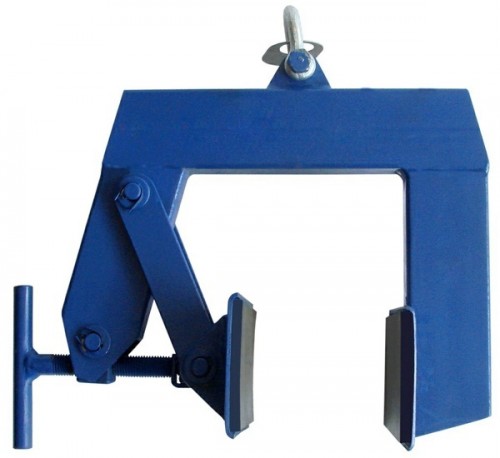

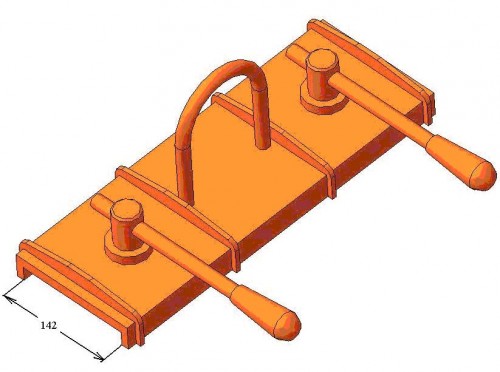

Grips for mounting sandwich panels are mechanical and vacuum.

- Mechanical captures.

Capturing clamp has a screw mechanism. With this capture, the panel is raised in a horizontal position.

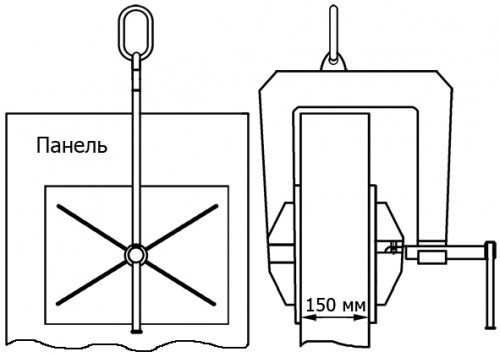

Fastening diagram when using capture - clamps.

Mechanical captures of "Main - Vira" allow you to raise the panels in a vertical position.

- Using vacuum grips, the panel is attached within a few minutes. They are more comfortable when working. The cost is more expensive than mechanical.

In order not to spend money on expensive equipment, take a rental tool.

When using vacuum captures, remove the protective film in the places where the capture will be attached. You do not need to remove the entire film - this is done after installation.

After the panel is fixed in the grip, it must be raised to height. Well, if there is a lifting faucet. If there is no crane - use the winch.

General Rules for Mounting Sandwich Panels

- Preparatory work.

- Install framework.

- Wooden designs to handle antiseptic.

- Metal structures protect against corrosion - clean from rust and apply primer for metal.

- Perform a sealing gasket. For panels with a polyurethane insulation, a mounting foam is used. If the insulation of mineral wool is a gasket performed from the same material.

- On the framework of frame elements, stick the polymer tape, or apply silicone sealant.

- Intermediate work.

When docking panels, apply silicone sealant on the castle.

- Final work.

Install the nicks to the place of the joints, slopes and angles.

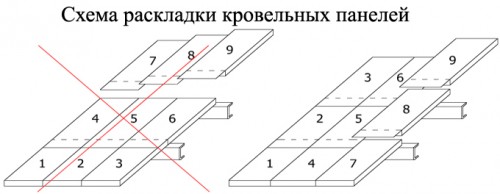

Installation of Roofing Sandwich Panels

Tools and materials

- Slings and grippers for lifting panels.

- Scissors for metal.

- Haysaw with small teeth.

- Sculpture.

- Wooden scraper.

- Level.

- Cord.

- Panels.

- Selfless.

- Means for sealing joints.

- Nicknames.

To prepare for the installation of the roof panels, wooden rafters are installed taking into account the slope of not more than 7º.

The most difficult when installing roofing szindwich panels is to raise them.

It is important not to damage the castle. If you do not have grippers, lift the panels on soft pins on the pallet. Carefully refer to the coating - damage to the coating will cause corrosion of the upper layer.

- Inspect the locks. Mineral wool should not stand for the inner shelf of the castle.

- Surplus cotton wool remove the wooden scraper.

- Installation start from the ridge of the roof.

- The first panel is attached to an open wave towards the end of the building.

- Align the edge of the panel at the end of the building.

- Check how much swells panel. Observe the distance specified in the project.

- Tension cord on the ridge of the roof. The edge of the panel should go parallel to the axis of the building.

- Secure the panel. Use special self-tapping screws with a rubber washer. Self-tapping screws are located apart 50 mm, twisted at an angle of 90º to the panel. Do not twist the screws deeply - you can damage the top coating layer.

- After mounting the first row of panels, apply a seal to the locks to seal the joints.

Installation of wall sandwich panels

In addition to the tools needed to install a zindwich panels on the roof, you will need a plumb.

Wall panels are installed in two ways - vertically and horizontally.

The vertical method is convenient with the height of knowledge from 3 to 6 m. The panels are fastened with self-draws closer to the base and roof, the locks provide a solid grip of the panels.

With a horizontal method of fastening easier to connect locks. Panel weight provides reliable clutch of locks.

Panels are attached along the edges to the frame. Start mounting from building base.

Installation of the Szondvich panels on the slopes

Sandwich panels for slopes are produced matte or glossy. Such slopes usually call plastic.

- Secure the starting profile by self-draws.

- Cut the panels in size using an electrol bias.

- Apply the mounting foam to the slopes.

- Install side slopes.

- Fill in the mounting foam, the discourse between the slope of the window and the sandwich panel.

- Install the finish profile.

- The top panel is attached to the side. The principle of installation is the same.

- Fix the panels and the finishing profile by paint scotch, to prevent palas overcast with an increase in the volume of the mounting foam.

Installing the sandwich panels on the roof. Video.

Installation instructions.

Installing slopes.