How to make a metal frame for a staircase yourself. Master Class Ladder

Among the materials from which the frames of stairs are manufactured, the metal is most reliable. Metal frameworks of a new generation may have facing and be invisible to the eye, and can be fully open for review, and at the same time harmoniously combined with the environment.

Content

Varieties of metal frames that can be made independently

Stairs on a metal frame are universal. They can serve to enter the house and in the cellar, as well as for lifting the floors. For the manufacture of an iron frame of the stairs without the help of specialists, it is necessary to have some basic knowledge about the welding process, but in general this procedure is not so difficult.

To make a choice of a variety of framework, it is necessary to decide on the view and design of the straightened staircase. For example, it can be screw, march, etc.

There are three main varieties of frames of a metal staircase:

- Hidden frame. This option is the most economical. It is assumed that in the process of mounting the stairs, all parts of the frame will hide under its elements, so it is made of the cheapest materials and does not look very aesthetic.

In the manufacture of this version of the frame, the only thing that should be carefully calculated is its strength, because The negligence attitude towards this aspect can lead to sad consequences, such as injuries and the leading work.

The staircase of the closed type is the carrier base made of metal profiles with a P-shaped cross section connected in pairs in some places. Metal corners are joined as a support for steps to them. With the subsequent installation of the stairs, they will hide under wooden and plasterboard decorations.

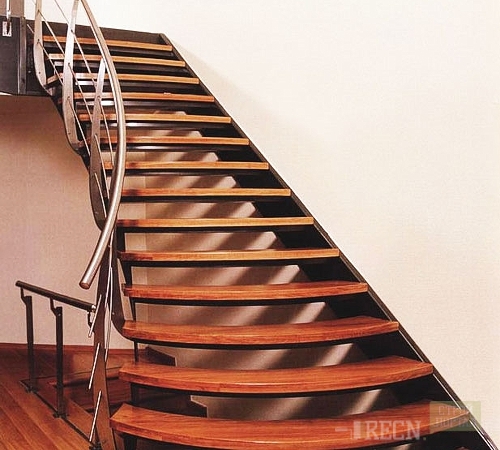

- Open frame having two cowra. Kosur is the carrier element of the framework on which the steps are stacked. This type of frame is made from the profile pipe with a square cross section. Kosomers repeating the shape of the staircase cover enamel. After fixing the steps and railings, the installation can be considered complete. The staircase with an open frame looks beautiful and exquisite, but has such a significant minus as a higher cost compared to the first option.

When making an open frame with your own hands, welding should be made as carefully as possible so that its traces do not spoil the whole view after the enamel coating.

- Open frame having one Kosur. In fact, it is the only carrier beam to which platforms for steps and corners are attached. Such stairs look light and transparent. In the event that they are planned large enough, there is a need to add additional consoles on the sides to avoid strain steps when exposed to large loads.

Tools and materials that will be needed to make a frame

For the manufacture of a metal frame of the stairs with their own hands, the usual tools will be required, with which many other operations can be performed. Their number includes:

- bulgarian (if there is an opportunity, then two: one having a 12.5 cm disc, and the second is 25 cm);

- drill, in power exceeding 600 W, as well as drills for metal;

- apparatus for welding;

- hoven for metal;

- file;

- various levels (no less than two: one length up to meter, and the second more than two) and squares;

- spanners;

- hammer;

- welding mask, protection for hands, eyes and bodies.

It is better not to save on labor tools. You should buy a professional level tool made by a well-known manufacturer. Only so you can be insured against unexpected failures and breakdowns in the most responsible moment, as well as from injuries and damage, the more so the handicraft tool is not much cheaper.

As a material for making a staircase, serve:

- profile pipe having a rectangular cross section. It is more rigid than a channel and is therefore better suitable for this design;

- primer for metal surfaces;

- enamel;

- degreaser;

- rust converter.

The frame made from the profile pipe has many advantages, for example:

- very reliable design;

- long service life;

- uncomplicated installation, both in the room and on the street, requiring the minimum amount of time and strength;

- from this material, you can make a frame and a railing of any form and configuration, using a wide variety of decorative elements;

- the profile tube is the most economical material used for the production of staircase frames.

Another advantage can be considered the manufacturing technology, which makes it possible to paint the structure in any colors using the powder painting method. In this regard, it is possible to choose any color suitable for a particular interior.

How to make a metal frame stairs

To weld the frame of the stairs, you must have at least a small experience of using the welding machine.

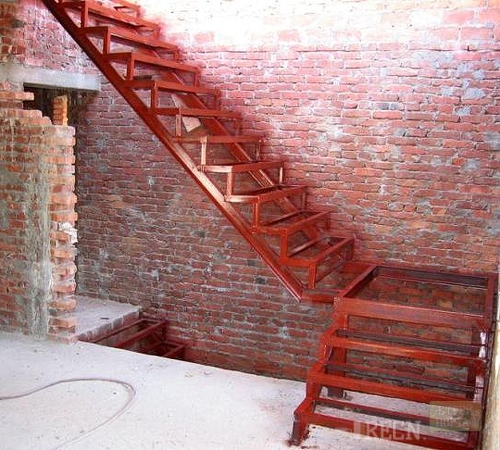

The process of manufacturing a staircase frame occurs in such a sequence:

- first of all, it is necessary to post, and when you cut profiles and weld the frames for steps;

- relieve steps;

- install the boosters;

- weld corners for steps;

- swift them with each other.

Next, you can discuss all working moments in more detail. Installation should always be started with thorough measurements, calculations and selection of the staircase type, which frame will be made. It is possible to manufacture any kind of personally, but before that it is necessary to decide which size will be steps and spans, which will be the angle of inclination, etc. If a single staircase is planned, its tilt will be approximately 45 degrees. The same applies to stairs with several marches.

On the stairs installed from the more hollow material, it goes much more, but the steep stairs are inconvenient, and sometimes dangerous, so they are installed for moves, which are used only occasionally, for example for attic.

In order to measure the march length, it is necessary to pull at an angle of 45 degrees with a rope from the top of the opening to the floor. So we get the lower point in which Kosur will be fixed. To make the calculation of the number of steps, it is necessary to measure the height of the room in millimeters, taking into account the overlap thickness, and divide it to the height of the stage. The most convenient for most is the height in the range from 18 to 22 cm.

What will be the steps in width, determine, pushing out the march length. The most comfortable is the width of 25 to 32 cm.

Upon completion of all preparatory work, you can finally begin to install. Consider this procedure using the example of the three most common types of stairs:

- Marsh stairs are the easiest for beginner option. First, a special platform is manufactured, which will make the staircase not so cool. At its edge will be attached to the lower part of the Kosomrov.

If the staircase is done without turns, then the platform is not needed, because It is very important to take into account the point of attachment of the platform between clean floors.

Next, the profile pipe is screwed to the lower end to the platform, and the upper is fixed by anchors on the wall. Then the corners prepared in advance are welded. The height should be extinct in accuracy, but the width is allowed more, the main thing is that it does not go beyond the profile pipe and did not create obstacles to the decoration of the structure.

Steps can be attached by one of the two existing ways:

- laying them on corners that are completely hidden under them;

- additionally, two fragments of the corners are attached to the corners, welded to the profile pipe so that the frame is formed with them to be inserted into the steps.

The staircase is better to mount so that between it and the wall can be turned and glued to the wallpaper sheet.

After that, on the sides of the profile welding, fences are fixed. If you install them not on the side, but along the edges of the steps, the staircase is somewhat narrowed.

Upon completion of welding, you need to polish the seams to remove burrs, and before painting, treat all the surfaces of the primer to avoid the appearance of corrosion.

- Screw stairs. To independently make the basis of the screw staircase, you need to stock up enough long pipe, which will serve as a central post, and the steps will be mounted around the spirals. The larger diameter pipe is still needed directly on which they will be fixed.

The pipe for fastening the steps must be divided into segments, constituting 23-26 cm. In length. So that later the angle of attachment came out correct, it should be cutting it strictly perpendicular to it.

Cut pipes must be tightly put on the central support, while not moving and not moving. If you find diameters with such accuracy it did not work, you can independently make sealing rings from the suitable rod.

To get rings that are sitting as it should, the rod must be screwed into a smaller diameter pipe. Next, the finished rings should be welded from the inside to the cuts of the pipe and clean it on the subject of roughness manually.

To make the size of the steps the same, you need to make a special conductor for them. To do this, you need a mandrel for the pipe and wooden slats. They must be glued in the form of a step.

After that, it's very easy to cook all the steps, the vagina tube into the conductor made before this and turning them at the desired angle. In parallel, each step is welded to its cut pipe. After graduating with welding, you need to clean all the seams from burrs.

Now it remains only to assemble the framework details. On the central support, we put on the segments of the pipe with steps and install this design in the place allotted for it.

After it is done, all the steps give the right angle and for reliable fixation to weld them together with short-lived racks. After primer, painting and drying on the frame can be mounted steps.

- Stairs having a special design. If the room is arranged in such a way that only a cool staircase can be installed in it, the angle of inclination of which exceeds 40 degrees, then the steps are better installed in pairs opposite each other. Such a feature of the design allows you to get rid of such a substantial minus as an uncomfortable ascent, but it gives rise to another minus - only one foot can get up for each step, on the right - right, on the left - left. For this reason, the movement on the stairs occurs in the march. In this regard, it was called "duck step".

The frame of this model of the stairs is the same as the remainder frame, the complexity lies in the manufacture of steps. Their foundation is made from profiles with a square cross section. All steps are made individually and then attach to Kosomers.

The manufacture of a staircase is possible using the drawing and separate cutting of each step, but for the most successful result, the conductor should be created on the principle described above. Ultimately, there will be a need to carefully measure the corners of the steps. When the frame will be ready, it will also be necessary to clean it in the seams area, handle the primer, paint and dry.

When preparing for work, it is necessary to understand that the welding process has many features and pitfalls. Without the idea how to handle the welding machine, you can very quickly spoil the design, which reduces all the applied efforts. For this reason, you should not make any attempt to weld the metal frame yourself, if you do not have enough experience or it is generally absent.

The most reliable, economical and attractive from the point of view of the appearance are stairs on a metal frame. Photos and videos with visual instructions for their independent making can be viewed below.