Placeetallic panels in the interior. Facing panels GML Walls

As the construction sector develops, more and more requirements are presented to building materials and methods for finishing various premises. The latest technologies are being developed and introduced, the market has increasingly reliable, eco-friendly, easy-to-use materials that make it possible to implement any designer ideas. In the list of such materials there are placeetallic panels applied during wall cladding.

Content

What are the panels from the placeetall?

Answetallic panel (GML, GMP) is essentially drywall clothed in a metal sheath. It is used at the final finishing of the indoor surfaces. The material is very convenient because it does not require any post-mounted processing. He does not need a putty, nor paint and varnish coating, no primer. The GM panels are characterized by simplicity of installation and dismantling, after manipulation with them a very little garbage remains.

The plaster plate has the following structure: as a shell of enclosing plasterboard from mechanical damage, a metal sheet is used approximately 0.5-0.7 mm in thickness and the base for the final polymer coating. Metal applies three types:

- steel galvanized;

- aluminum;

- stainless steel.

There are also three options for the final polymer layer:

- polyester spraying;

- vinyl deposited layer of half a millimeter;

- polumillimetrovy sheet of stainless steel.

The most widely used polyester sputtering and theremocrack with a compound of polyester and epoxy resins. Under the influence of high temperatures, their microparticles are polymerized on the surface of the metal and form a durable coating, resistant to abrasion, shocks and deformations, not fearing UV irradiation and temperature differences, which has been corrosion.

As already mentioned, the core of the panel is a sheet of plasterboard, which is the basis forms its form.

Plasterboard is a material consisting of an imposed burning of the core from the gypsum, placed on all sides, besides the ends, cardboard.

Based on the functions that will perform the GM Panel and the Areas of its use, manufacturers close to the shell of metal Various types of plasterboard plates:

- ordinary;

- moisture resistant;

- with elevated refractory properties;

- combining refractory and moisture-resistant qualities.

Depending on its sizes, the following dimensions have prepared placeetallic panels:

- the width is approximately 60-120 cm;

- length - 60 cm. - 4 m;

- thickness from 1 to 1.3 cm.

Firms Manufacturers of GM panels, manufacturing them to order, follow the dimensions that are not overlooking these frameworks.

To glue a metal sheet to a drywall, a special waterproof glue is used, which makes the connection stronger and reliable than both parts of it separately, and the panel is perfectly smooth. Such a connection gives the stove resistance before different kinds of damage and extends its service life for many years, ensuring the preservation of the appearance.

Method of installation of placeetallic panels

The GM panels are mounted on the ceiling, walls and linse the partitions. Most often, they are attached to special designs for metal, but it is possible to mount on plaster or a wooden wall. If the panels are attached to a mineral base, then its surface must be perfect smooth. Fix them with sixmillimeter dowels.

The base for walls of plaster panels is constructed from galvanized profiles, the walls of which are 0.5-0.7 mm in thickness, using direct suspensions. The frame is going to use the same technology as when working with ordinary plasterboard. But in the case of the GMP, the racks should be placed with an interval of 60 cm along the axes, it often does not make sense. In addition, the carrier profile is permissible to have horizontally at the same distance from each other.

Wall facing panels can be made in two ways:

- independent;

- stationary.

With any of them, all components of fasteners are hidden in the seams area. Self-tapping screw in this case are not used.

If when installing was used independent waySubsequently, if it is necessary, each panel can be removed separately. The mount is carried out as follows: During the assembly, the sides, existing on each side of the GM panel dock to each other or make the brass and in this case the fastening screw passes through two layers of metal. With this method, the installation remains a fairly large gap, which is hiding under a special profile.

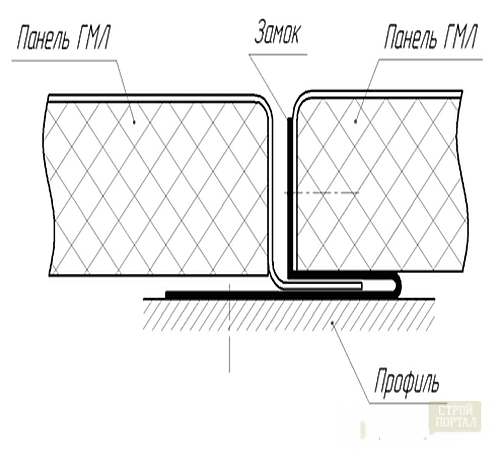

If the assembly is carried out by stationary fasteningThe surface is constructed on the principle of pitching of spikes and grooves for a more reliable connection. At the ends of the panels, with the help of metal screws, metal locks are fixed, having the same coating as well as the plaster plates themselves, at the rate of two units per meter mounted during wall mounted, and four units per meter running when mounting the ceilings.

Next, the petals of the groove-lock are attached to the carrier-based screws, the spike of the next panel is included in the grooves of the previous one, etc.

But with any selected assembly method, there is a need to seal the locations of the panels. With the first embodiment, quite large gaps of 8-10 mm wide are obtained. It is covered with silicone figured seal. If a second option is selected for attachment, the seams will turn much thinner - 2-5 mm, they can be filled with silicone sealant.

If we are talking about the ceiling trim, the placeetallic panels are mounted without using mechanical fasteners. It is necessary in order to be able at any time to quickly get into the inter-station space where there are communications.

The end of the panel, the seats of the ceiling and walls, internal and external angles are masked by framing profiles. In order to prevent the presence of hard-to-reach zones, in which it is impossible to clean and disinfection, internal and sharp corners are closed with a swarm with a rounded cross section. Most often, their length is three meters, and they are made from aluminum. But there are dogs made of rigid plastic and having an outer colored layer.

The main properties of GM panels

The GM Panels differ sharply from the existing facing materials. In this regard, the area of \u200b\u200buse has its own specifics. The main positive qualities of this material:

- GM cladding is 100% hermetic, i.e. The air indoor is not mixed with the discharge of materials that were used for the draft walls of the walls, the panels are airtight;

- because Surfaces are matte or semi-bright, they do not even glare with very bright light, falling on the side, which means they do not interfere and distract the staff from work;

- panels do not have such places where dust or dirt can accumulate, because All seams are sealed, the fasteners are hidden, and the angles are rounded;

- due to the elasticity of the seams, the design can be used even in seismic places. Also, the panel perfectly transfers vibration emanating from industrial equipment and increased pressure;

- the final layer, which is covered by GM-Plates, does not release any substances into the atmosphere, resistant to the effects of household chemicals and disinfection means. This coating has no pores and rough areas capable of accumulating dirt or moisture, has antibacterial properties, thanks to its composition of silver ions.

- The GM panels easily combine with communications, doors, lighting devices. They are shutdown in them with efforts for hoods and heating lattices;

- GMP does not differ in great flammability and toxicity, so in case of a fire, it makes it possible to navigate and leave the premises.

Where the facing panels are used from the placeetal.

In other words, this material reveals the full range of its advantages when used in so-called, clean rooms. These are rooms in which the environment is strictly monitored for the absence of it or minimizing microbes, dust, chemicals. In addition, in these rooms, temperature regime, pressure and humidity level can be adjusted.

The main areas of using placenetal panels:

- Medicine. This material is discharged by walls in operating, resuscitation departments, family halls. In addition, in scientific laboratories, too, it is impossible to do without GM finish, thanks to the stable environment provided by it. In this area, the placeetall is used most often.

- Different industries. In the production of products in the field of pharmacology and microbiology, a stable medium is also very important, since The presence of foreign particles in it can be quite noticeable to affect the properties of finished products. The same can be said about the production of semiconductors, and the food industry.

Recently, the placeetall has become widely applied not only for clean rooms:

- This material began to be eagerly used for cladding warehouse, garages, workshops. Strength and water repellent properties allow it to apply it even on car washes and in car service.

- GML fell silent by High-Tech style fans. On the joy of them, recently, panels imitating the surface of marble, wood, metal appeared among the variety of colors.

- Today, GML is increasingly used for cladding office premises, buildings of business centers, as well as for the design of nightclubs, cafes, and sometimes residential cottages.

With the help of placeetallic plates, you can get at the same time an attractive interior and a stable medium corresponding to sanitary and hygienic standards.

What is the cost of a plastertal and what does it depend on?

GMP - rather economical material, because Manufactured in Russia using imported lines. With his order of the company, manufacturers usually try to deliver it to the buyer during the shortest possible time.

The cost of the square meter of the GM-Plate begins on the seven hundred rubles. Further, depending on the necessary properties to the customer, it may increase:

- when ordering an unusual color;

- if you need to use as the core of the plates of other types of drywall, for example, if the customer wants the material to be fire-resistant or had water-repellent properties, or has noise insulation.

If we add all the surcharges, then the cost, at first glance, it turns out not so low. But if we take into account that the GMP does not need to be prepared for installation and can be used immediately, and the process of the object itself is extremely simple, then the benefit becomes obvious. It is only worth estimating that the multilayer design, created when using conventional facing materials, and add funds here, which will be paid by the workers, and the cost of the guitonetal no longer seems so big, and often even much more profitable.

In the area of \u200b\u200bcladding clean rooms, plates from the plates of the plates occupy a leading position. The number of their competitors is minimal. In practical and functional indicators, the panels from layered plastic left the GMP, but their initial price is almost twice as high. Other facing options, such as tile laying, painting walls latex dyes, gypsumnil, do not go to any comparison with GM panels, and do not have a sufficient set of qualities in order to be used in rooms where it is necessary to maintain a high level of purity.

Of all the above, we can conclude that GMP is an advanced modern building material, which has a number of unique qualities that put it on the step above the traditional ways to facing surfaces in the premises of increased purity.