How to make roof frame Useful advice

During the construction of any structure to its carrying parts, special requirements of strength are presented. The main bearing elements are the foundation, walls and roof. In this article we will talk about how to make the roof frame correctly, what installation methods are used today and how to save on construction work.

Content

Types of carcasses

There are several types of roof frames, the choice of which depends on the type of roof, the nature of the coating and destination of the building.

Roof frames come:

- wooden - a rapid system that is used to create pitched roofs in housing construction. The most common appearance;

- metal - metal roof frame is used mainly for industrial construction, since the installation is very costly and suggests large volumes and areas;

- reinforced concrete - flat roof, carrying the base of which is made of reinforced concrete plates.

In this article, we will not stop in detail on the metal frames of the roofs, because it is almost impossible to make such work. This type is not suitable for housing construction, so we will tell about all the subtleties of the construction of wooden frames.

Types of the rafter system

Before embarking on the construction of a roof frame with your own hands, you need to determine which type of the rafter system you will use. The main purpose of the rafter of any pitched roof is to be support. The rafters or rafter legs are wooden beams with a cross section of 150x50 mm. The drying and roofing coating are stacked over the beams.

The following types of roof frames are distinguished depending on the connection of the rafter:

- current;

- hanging.

For private construction, both of these species can be used, the difference between them is only that Maurylalat is used in the hanging system. Mauerlat is a longitudinal bar 100x100 mm. If you use the sleeve rafters, their upper part will rely on the central carrier wall, and not connect to each other.

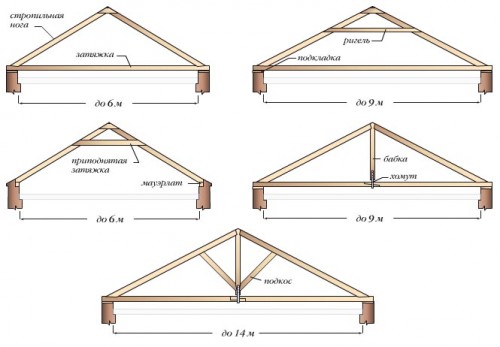

To choose one of these types of systems, it is necessary to take into account the planning and design characteristics of the building. For example, if there is 6 and less than meters between carrier walls for support, it is advisable to use the hanging roof frame. For spans between the supporting walls with a distance of more than 6 meters, it is better to use a change system with an additional "intermediate" wall in the center of the building. Thus, the rafters will not be saved with large spans. But this condition concerns only wooden frames, for metal spans can remain without an additional wall.

FEATURES OF MONTAGE

To answer the question "How to build a roof frame?", It is necessary to deal with the theory of mounting.

The roof installation can be carried out in two ways:

- Finished farms - a system of reinforced rafters using tensions, racks and dies. First, all non-judging design is assembled, consisting of the same type of elements, and then it is installed on the roof of the building box. The whole process takes a minimum of time, but the involvement of lifting equipment is required, and, consequently, the costs will be quite large. Ready farms are advisable to put for roofs with large departures and without support.

- The roof frame assembly is a more affordable and budget way, but its implementation requires more time. The assembly passes in gradually, but you can quite cope with your own. How to assemble the roof frame we describe in more detail below.

In the process of designing the roof frame circuit, the following important factors should be taken into account:

- The design should withstand the load of varying degrees, including its own roof weight and all elements, the weight of snow in the winter time, the wind pressure, falling foliage and so on.

- Choose a roofing coating with maximum waterproof, especially if you live in the area with a wet climate.

- Make the thermal insulation of the roof with minimal heat loss. To do this, it is necessary to ensure full-fledged waterproofing and vapor barrier, and also consider the roofing space system.

- The attic room must be ventilated. This will prevent the damage of the structural structures, thereby increasing the service life of the building.

Choosing materials

If you want to know how to make the roof frame with your own hands, first you need to get tools and materials.

To perform work, you will need the following:

- bar 150x50 mm for rafters;

- bar 100x100 mm for Mauerlat (for this purpose it is better to buy coniferous wood of winter workpiece without any visible flaws);

- rake 40x40 mm for crate;

- fasteners for fixing Maurolat;

- studs 8 mm and 10 mm for rafters;

- brackets;

- brackets;

- self-tapping screw;

- hammer;

- plane;

- drill;

- saw;

- level;

- roulette;

- gloves;

- antiseptics for wood;

- antipirens.

The processing of wooden structural elements with antiseptics and antipirens extends the deadlines for the operation of the entire building, and also reduces the flammability of wood, reducing the risk of ignition to a minimum.

Useful advice: greatly simplify and speed up the installation of gas pistols. On this video, the roof frame is made easily and quickly with the use of modern techniques. If the construction is disposable, it makes sense to take such a gun for rent.

To perform a frame from a metal profile, there will be completely different tools, but since the weight of the materials and the complexity of execution do not allow you to do such a work itself, the most reasonable to engage in the construction of wooden frames.

Frame of a bantal roof

When you purchased all the necessary materials, prepared the tools, handled the wooden elements with protective compositions, can be started. Construction of a row-type roof frame should be started with Maurolala styling. This bar will distribute and transmit a load from the rafted to the bearing walls. As a rule, Mauerlat is placed on a concrete base on the inside of the carrier wall.

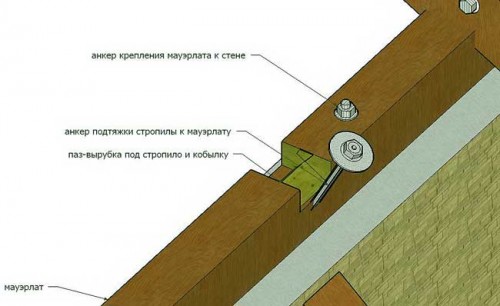

So that the wood did not stretch all the moisture from concrete, and after that he did not crumble, there should be several layers of rubberoid under the bars. From the outer wall, it is necessary to make brickwork to the level of Mauerlat, and, in turn, to attach nuts and studs to concrete.

Slinge system

After the construction and strengthening of the base, it is possible to carry out the construction of the roof frame, that is, to install rafters.

Setting the rafter consists of several stages:

- Determination of the string step. As a rule, the step of the rafter ranges from 80 to 90 cm, which corresponds to the size of the sized bars.

- For attachment, the rafter should be pre-done the holes in Mauerlat.

- Usually the roof frame device should be started from the front of the facility, that is, from the end parts. At both ends of the roof, install the end rafters, and then pull the cord between their skates. It will help exactly exhibit intermediate elements.

- All rapid legs fix on Mauerlate brackets and steel brackets. The rafters should go beyond the perimeter of the structure of about 40 cm. If it does not work out the sink of the rafter, it is possible to increase it using a special-making bar with a smaller cross section, attaching it to the rafter with ordinary nails.

- To fix the lower part of the rafting legs, use the strapping based on Mauerlat. If the rafter is not long enough, increase it, leaving another bar with the allen. Fall must be made large - no less than 100 cm so that the roof does not lose stiffness.

- Frames Roofs of houses with 6-thyme spans are not possible without tightening devices between rafters. They are installed between the support rafters so that the whole design is visually similar to the letter "A".

- When all the rafters are installed, it is necessary to fix them in a smooth vertical position. To do this, use the skiing bar by setting it in the upper part of the structure.

- After that, it came a turn of the arrangement of the crate. If you plan to use soft roofing materials, you need to make a solid crate of moisture-resistant plywood or OSB-plates. If you break the roof by slate, professional flooring or metal tile, the lamp should be shoved. To increase strength, take a solid crate, regardless of the type of coating.

Construction features

How to make the roof frame is more clear, but that the results of your work continue to please you for more than one year, you need to take into account some nuances in construction.

The following recommendations will help significantly simplify the construction of the roof frame:

- Remember that the installation step of the rafter and the selection of sections is interrelated values. The smaller the cross section of the beams, the less step will be. This will be useful if the size of the timber does not correspond to the load.

- The rafters can be free or loaded (maintain the beams of overlaps).

- Connections all nodes and fasteners should be as reliable as possible. To provide additional stiffness, use enhancement overlays.

- Carnate rafters to Mauerlat can be in several ways. Dogs give more rigid fixation, and special sliding fasteners are ideally suited for chopped homes.

- To protect the outer walls, the scene and the foundation, the roof should go beyond the box not less than 40 cm, and the end parts of the rafter is better to protect the frontal (wind) board.

- If you are using hanging rafters, remember the load that they give on the walls, so fasten the rafter feet with a tight. It can be both a bar and overlapping beam.

- Choose the shaft step in accordance with the nature of the roofing coating. Different types of coatings have their own ranges depending on the degree of slope.

Features of the construction of a duplex roof, as well as tips how to make a roof frame in video materials below: