Kuznetsov furnaces. Design, drawings, spokes Construction

Since 1962, the Inventor Engineer Igor Kuznetsov is developing and improving the furnaces. In his arsenal, more than 150 models and the demand for them have a very different categories of the population growing steadily.

Content

Principle of operation and differences from other heating systems

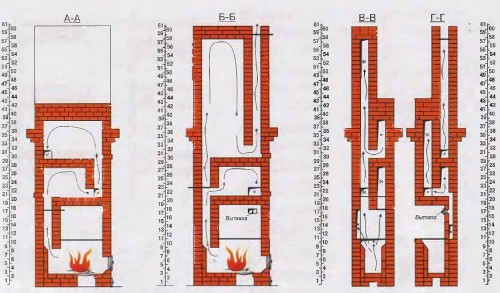

The basis is the principle of free movement of gases. To circulate air in a conventional oven, it is necessary to expose to external energy, that is, creating forced thrust in the pipe. When gases are in a closed space, with a permanent heat source, they are divided under their own weight - cold settle down, hot climbs upstairs. At the same time, in the area of \u200b\u200bhigh temperatures, the pressure is growing, and where it is cold - energy is discarded and produced. It turns out, the turbulent movement arises automatically thanks to the laws of physics. This means that if it is competent to send convection streams, then thermal energy will be transferred to the masses themselves. The merit of Igor Viktorovich is that he managed to subjugate the system of free movement of gases and use energy produced with maximum efficiency. One example of Kuznetsov oven can be seen in the photo below.

With electrical heat supply of the traction pipe is not required. If the furnace is heated with firewood, then the combustion product is invariably to go out. Thanks to the cunning design, it accumulates at the last stage of his way, turning out as if under the cap. There he burns out again, to the end giving his heat, and then in the form of useless gas is excreted into the street, without cooling the system. Such furnaces are also called the cap.

The fundamental feature of the gas filling of cavities is that, no matter how much compartments in the furnace are, they are all filled with gas evenly and in all the same physical processes occur in all. Create something similar with the help of thrust, the principle of counterflow (widely used in Europe) or other convective methods is impossible. That is why such furnaces are innovation in the furnace heating system.

They regulate themselves and, whatever the configuration they attached, they always work on the natural principle. This gave a worst of engineering thought of the Creator, as a result of which dozens of heating systems of various appointments and power were invented:

- russian coarse stoves;

- furnaces for baths and pylons with water temperature regulator and steam;

- various household ovens with cooking surfaces and layers;

- the fireplace in which the walls of the fireplace are cavities of the furnace and besides the aesthetic, perform a heating function;

- for two or three-storey houses - multi-level furnaces with a transit pipe;

- system of ovens of various purposes in one house, which work for one chimney.

Kuznetsov's cap ovens can be equipped with a water boiler and represent a hot water supply system in the house, while heated from electricity. Such a reserve significantly reduces costs.

The main advantages of furnaces:

- Efficiency. The efficiency comes to 93%, while modern furnaces give 70-80%, Russians - 30%.

- Uniform warming ups the brick and masonry, without giving it to crack.

- A smooth temperature distribution prevents the appearance of "pit" with cold air.

- The stream stream is more resistance, with the result that there are no problems with fireplaces or multi-storey furnaces.

- Smoke from burning the fireplace enters the stoves and joins the overall heating process.

- Good keep warm even with an open valve.

- Practically not clogged soot.

How do you build a furnace Kuznetsov?

Start standing with the definition of its correct location and preparatory work. The walls of the furnace should be placed so that all the rooms are heated, and its power should fill the thermal loss of the house. To do this, draw the room plan and draw a location. The docking of interior partitions and the furnace should occur through fireworks, and the gaps between the chimney and rafters must also be observed, as well as other wooden floors elements.

Kuznetsov furnaces and their drawings are presented for free access to any Internet user. From their huge set you can only choose the appropriate type and exterior. Any of them can be performed in the mirror version if necessary. A lot of videos of material and countless explanations are removed, so, if there is a desire and perfection, you will achieve a good result.

There are such concepts as heat transfer and heat loss. So, before the start of construction, it should be calculated by the loss of heat at home. The calculation of wall materials, outdoor insulation, plaster, double-glazed windows, basement or foundation, floor structure, ceilings, all internal partitions and decorations. Plus the area in which you live. Each material has its own density from which the coefficient of thermal conductivity (such tables are already compiled). Take into the calculation also a comfortable temperature for you and according to formulas, calculate the total heat loss in W / m² units.

Now choose from the catalog oven that whose heat transfer speed compensates for the loss of your home. Each square meter of the oven with two furnaces per day gives approximately 500 W per hour, that is, the design of 1 m and 2 m with a height of four sides gives 4 kW of heat per day. Disposable firebox reduces this indicator to the coefficient of 0.6-0.7. For comparison, many foreign manufacturers indicate several times greater power of their furnaces, but this is explained by all the same low efficiency when more energy is required to achieve efficiency.

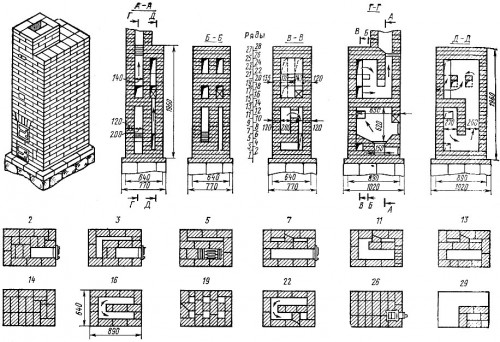

What else to consider before starting? All Kuznetsov furnaces are decomposed on orders - layer laying. The minimum element size is 1/8 bricks. All gaps, distances and holes are indicated by a fraction, for example, 3/8, 1/4 bricks. Thus, regardless of the size of the material, you can underestimate the correct design.

Adopted recommended materials and parameters:

- outdoor masonry: clay brick 250x120x65 mm, minimum brand - M150;

- inner masonry: Brick refractory chamotone SB-8 250x123x65 mm, W-5 230x114x40 mm;

- seam of outdoor masonry - 5 mm;

- the height of the row with a seam is 70 mm;

- 100-130 kg of high-quality clay and peeled sand without organic impurities, about 1 mm, at the rate of 1: 2 or ready-made slope dry mixture at the rate of 0.2 cubic meter by 500 bricks;

- metal accessories: valve, flue and confusion, grate grille, 2 steel corners, 5 m wire.

Any construction begins with a good foundation. It is made of concrete or boot, diluted with cement with a protrusion of 5-10 cm throughout the perimeter of the furnace. The top level is flush with the foundation of the house. Next, the base is littered with a rubberoid or another insulator. The desired level is reported brick taking into account metal corners for fire issues. It is unacceptable to top up the concrete mixture, since the masonry will subsequently be embossed unevenly.

When the foundation is ready, we begin to lay the furnace of Kuznetsov regarding the scheme.

For fire safety purposes, it is impossible to use chamotte brick, as it threatens the oven overheating. From high temperatures, the refractory material is expanding, therefore, there is a gap of 5-6 mm between the external and internal clips. Horizontal cavities are filled with paper packaging cardboard, and vertical - basalt or kaolin wool.

Metal devices are included in the laying with an expansion gap of 5 mm. This distance is also laid by refractory wool.

What to do when the furnace is ready?

Before starting operation, it must be dried. First, protect the furnace 2 times a day by a small amount of fuel, avoiding paper components - the paper gives a sharp increase in temperature, because of which the laying is simply cracking. Be sure to open the damper and both doors, let the air circulate freely. Then the flue door closes, the amount of fuel gradually increases and the furnace will dry about eight days in summer and two weeks in the autumn-winter period. At the same time actively ventilate the room. The temptation accelerate the dryness is fraught with the outlet of the furnace before use. Observe the instructions also on the correct melting and operation of the furnace and feel free to apply for advice to a specialist, which will not give your design to fail.

The furnace on the system of free movement of gases is essentially very simple and spoiled it difficult. Completed by an individual project, it will turn into any interior and building structure. A huge number of Russian cathedrals, churches, monasteries are heated on this principle. To date, Kuznetsov's stoves have a lot of fans, both in the dwellings of rural residents and in houses of high-ranking faces.