Fire extinguishing systems: selection and installation Useful advice

Unfortunately, progress is largely the initiator of a different kind of disasters, in particular, a fire. It makes designers think about the urgent task - how to avoid a significant damage in the property and prevent victims. They created numerous fire extinguishing systems designed for the speedy localization of disasters based on the type of source. Details about the right choice and installation below.

Content

There are several types of fire extinguishing systems. Anyone is designed to safely eliminate the focus of a certain type of fire. They are a complex complex of circuits and sensors that react to the established parameters preceding open fire. So, automatic fire extinguishing systems include:

- Gas.

- Powder.

- Water, which, in turn, are divided into sprinkler and drainscore.

All types can be attributed to both domestic and production conditions. The automation is good because it allows you to quickly respond to what happened with minimal losses, without the participation of personnel by. Read more about the advantages and disadvantages of each talk further.

Gas fire extinguishing system

Today, such a complex is a progressive product among existing fire extinguishing systems, as it reduces losses to minimal, for, unlike other means, gas penetrates any hard-to-reach places. It is an interconnected pipeline cylinders or liquefied gas tanks. Management is carried out by control detectors and sensors. Used mainly in the control points - server, dispatching. That is, in places associated with electrical components and automation. As well as in the warehouses of securities or works of art. Two groups of gases are used as stewing elements - inhibitors and diluting. Read more:

- Inhibitors are gases that slow down the process of burning to complete attenuation. Interacting with a flame, chladones disintegrate on free radicals, preventing the spread of fire. The carbon dioxide used at the same time has a cooling effect on the focus of ignition.

- Dilute gases have a weakening effect on the flame and at the same time reduce the percentage of oxygen, which is a fire catalyst. These include nitrogen, argon and inergen.

The cons relationship of the gas fire extinguishing system is significant regarding the location of the alleged ignition. Installation requires compliance with important conditions, namely:

- The presence of free space for bulk automation. The amount of gas in one cylinder is spent quickly, and for extensive areas it will require a significant amount. In addition, such territories should be equipped with forced ventilation, starting work, after the center is localized and fully extinguished. In the calm state of the room should be sealed.

- Some gases are categorically not suitable for places of accumulation of people, since they are highly toxic substances. These include chladones and nitrogen. They can destructively act on metals. That is why installations with such content are suitable only for fully automated equipment, in the production of which resistant materials were used. However, existing progressive installations based on fluorourtone and steam make it possible to use them in domestic conditions without harm to humans and the environment.

- Gas equipment of this type is expensive. Moreover, the price increases with the number of safety sensors, the level of which is determined by GOST and their professional service.

Installation of gas equipment in terms of fire safety is carried out by public services. Security checks are held on time, regulated by documents and norms. An independent connection is not excluded, but for this you must follow the following conditions:

- When choosing overall systems, take into account the size of the room for installation and the ability to connect to an electrical network, as well as the presence of forced ventilation to remove air.

- A project-scheme of gas fire extinguishing, where the number of cylinders, pipe wiring, control panel and cable location are compiled.

- When buying a system, you need to make sure that you have all components: gas cylinders - modules, spare canisters, locking and starting device (PC), pressure alarms, spray guns, sleeves, manifold, couplings, pneumatic and / or solenoid drive, and Mechanical start, electronic scoreboards with warning inscriptions.

Warranty must be obtained for all parts and automatic devices. Next, the installation itself:

- First produce pipe wiring and its connection with automatic detectors and starting machines.

- According to the scheme, the modules have parallel to each other or the battery from cylinders separated from each other pipe wiring is installed. The main one must be equipped with the PC, pressure warning device and solenoid drive. His task, give the command from the main module to others. Together with it (drive) installed pneumatics.

- Then the collectors are connected to the cylinders to attach to the total pipe wiring.

- Flexible sleeves are needed to relieve mounting in large rooms. If this is not the case, use transitional couplings to connect to pipes at a small distance.

- The latter at the outputs of the gas are installed nozzles-sprayers with internal threads.

Gas fire extinguishing systems are a lot, but even the simplest one requires a professional assembly approach and subsequent maintenance.

Powder fire extinguishing system

Based on the basis of the focus of the focus of damage to the bulk substance containing salts of metals, which, when interacting with fire, disintegrate into non-combustible gases that prevent it. The powder fire extinguishing system has several advantages over other installations, namely:

- It is the only effective safe method of localization of fire in the territory equipped with power grids.

- Does not require a separate room, it is a compact setup with a sprayer. However, the connection still occurs under the control of the civil service specialist.

- The cost of the powder system is low compared to the rest.

- Does not require any features of the room.

However, there are deficiencies. It is the chemical composition of salts that is a serious obstacle in order to name this system of perfect and universal, namely:

- After the end of extinguishing, immediately eliminate the powder with metal parts, since at high temperatures the interaction is inevitable, and the formula of the bulk agent is able to break their integrity or even to derive the equipment.

- Such a fireproof installation is absolutely useless for the ability to fire without air access or tension. For example, forest warehouses or sawmills must be equipped with other means of localization of the flame.

- Spray mixtures are harmful to respiratory tract, so the process should go with the evacuation of personnel or home, as well as using personal protective equipment.

- Powder movement is difficult in long highways, unlike gas or water. Extra equipment will be required, which will lead the design.

A classic example of such an installation is the old good fire extinguisher of the sample OP-1, 2, 5, and so on. They can be downloaded or with built-in pressure sources. Universally used autonomous powder system, which is a module with sensors. Such a system is more than appropriate in household conditions and in small objects.

Powder installation includes:

- Module itself.

- Brackets for consolidation.

- Repair kit.

- Accompanying documentation.

To establish such a labor design will not be - the assembly scheme is present. But first of all, you need to learn all the documents and check the matching match and labels on the housing. It should also be carefully observed for the state of the module, because the service life is quite small - 5 years.

Water system fire extinguishing

Of course, the most famous and common way to get rid of such a type of disaster. It is divided into two types of installations - a drainage system of fire extinguishing and sprinkler. What is the essence of the differences in these designs, as well as their advantages and disadvantages - details below:

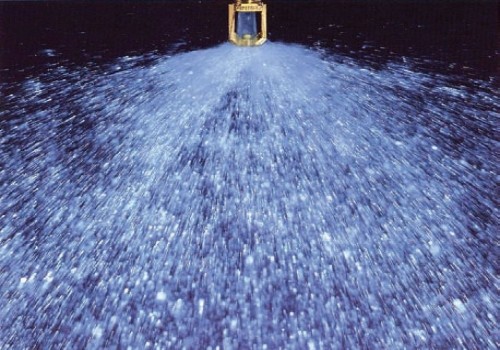

The sprinkler system is based on a thin spraying of water under greater pressure. Equipped with slotting sensors, sound and light alarm. Fastened mainly on the ceiling and does not represent difficulty mounting. Naturally, with understanding of all components. The advantages of such a design are indisputable:

- Water is an excessive resource, provided a central connection. This means that, in contrast to expensive gases, the cost of the installation will not exceed the known limits.

- Thin water dust is much better cope with fire, rather than the flow.

- Built-in sensors leave personnel or home enough time to evacuation.

- In addition to the design with the sensors and the control unit, only plastic wiring of water pipes will require.

But! There is always a risk of damage to your own property, as the liquid is destructive for such rooms as a library or gallery of paintings. Therefore, the selection and installation of fire extinguishing systems of this type should be under the control of specialists - some models allow you to avoid damage, since special sprinklers create fine water dust, the currently extended than the flow.

The drainuclear system, in contrast to the above, allows you to work not only with water, but also with foam. Its task is to create a veil of fire, thereby preventing it from exiting and spread to other places. And also has a deterrent factor for many chemically hazardous substances. Because of which it is predominantly used in the doorways at industrial enterprises, commercial organizations and other places related to the risk of fire.

There is a water system of fire extinguishing for today is the most common design that is coping with its tasks. The only disadvantage can be considered an inertial response of sensors to any air pollution, but experts will help to debug components.

Installation of both systems is as follows:

- First, they set the wiring of water pipes on the desired area, with a mandatory output for drakelers or sprinklers. They must necessarily include self-destructive locking devices and sprinklers. They themselves are located on the ceiling with a certain step - in 1.5-2 m.

- The main branch must be connected to the station, which includes the main pump, reserve, jockey pump and hydraulic to protect against impact. The equipment must be placed in a separate room and do not represent threats to life, as is associated with high voltage.

- Then the mounted equipment is connected to the central water supply system.

- The effectiveness of the installation is checked by the attached control panel using indicators. Many models have two modes - automatic and manual. Ensure in working condition, it is required in advance, without starting water.

Installation and installation of all types of fire-fighting systems is a complex of work with a complex system of nodes and sensors interacting with each other. A simple inhabitant is quite difficult to do independent work, in the absence of necessary knowledge. This is not the case where you can save on an outside strength - if the choice is entirely depends on the needs of the consumer, the installation of fire extinguishing systems is made by masters and at the end of the installation should receive all relevant certificates and other documentation from the public service.