Expanding cement. Features and application Building materials

The building materials market is constantly developing and offers to the consumer quite interesting multifunctional products. One of these new products is an expanding cement. Thanks to its peculiarities, it is ideal for overhaul.

Content

What is an expanding cement?

This is a special kind of cement, which, thanks to certain additives, increases volume. Due to such a feature, the material is indispensable in the construction of monolithic structures from reinforced concrete, as it allows you to fill all empties and cracks. In addition, it is used to build underground structures (mines and tunnels). In everyday life, the expanding cement is used not often due to high cost. Nevertheless, it is ideal for restoring walls in old houses and significantly reduces the flow of other materials.

It is often enough to designate this group of cements use the term "cement gypsogly-grade expanding". The name is associated with the method of material production. To obtain it, hydro-grade bases are used with the addition of various expanding components. Among them:

- calcium hydrosulfolum

- magnesium oxide hydrate

- aluminum sulfate,

- calcium chloride sulfate,

- sulphite alcohol bard

- aluminum powder.

All these complex chemical compounds under the influence of moisture begin to actively enter into a decay reaction. At the same time, the newly formed elements increase in volume and tie the cement molecules. Due to this, the material begins to increase in size. It does not affect the strength of cement, but on the contrary, makes it more reliable and durable. Among all these additives, the calcium hydrosulipolum is most often used, as this is one of the cheapest additives. But, the best is magnesium oxide hydrate. The rest of the additives are only a little inferior to it and in the domestic use of the principled difference do not have.

Advantages and disadvantages

As with any building material, the expanding cement has its pros and cons. Explicit advantages include:

- durability,

- the ability to fill in micro and macro cracks,

- the possibility of using as finishing plaster

- increased adhesion

- resistance to atmospheric and chemical exposure.

Important: in addition to expanding there are other additional components. They determine the type of cement resistance. Some are ideal for external work, others are specifically designed to operate in a chemically active medium, the third features improved adhesion, relevant when assembling reinforced concrete structures. Therefore, before buying cement, it is necessary to determine exactly with its type.

Disadvantages of the material are as follows:

- high price,

- bad distribution

- the presence in the market of a large number of fakes,

- non-profile.

Despite this, if you buy the goods of the proven manufacturer and use it on the intended purpose, the savings on other materials with interest covers the cost of the cement itself.

Expanding cement application

Such cement is indeed applied solely to solve only a few tasks:

- filling cracks

- reinforced concrete gluing

- outdoor plaster walls from the shell.

According to the general principle, all cracks are divided into micro and macro. Microcracks occur as a result of mechanical shocks, under weight, or even earlier, in the process of transportation. Externally, they are not visible, however, they become a niche for condensate. During the operation of the moisture expands microcracks. In winter, it turns into ice, in the summer melts. After a few years, such regimes appear macrobrees, which are already noticeable to the naked eye.

Having a magnificent adhesion, the expanding cement is absorbed into the material from which the design is built and fills all the pores from the inside. This is exactly what its use is due to the outer plaster (indoors, as a rule, a stable temperature regime, so condensate does not harm). Also rightly and in relation to macrobrees, the exception that the consumption of the material will be greater.

In the private construction of two-storey and more houses, reinforced concrete floors are often used. Usually they are placed on the walls on the walls and, at best, the usual cement is missing. It goes into incision with construction standards, since the locations of the reinforced concrete blocks must be monolithic.

This requirement is due to the fact that during operation, the load should be distributed evenly from the plane on the wall, otherwise the stove will begin on the joints, and the condensate will accelerate the destruction process. In private houses, the consequences can only appear after 20-25 years, but if the project is conceived as a hotel, then the need for repair will arise for 5-6 years. The process is quite complicated, as it will have to fill a part of the plate (build forests, make backups, formwork for the ceiling, etc.). It is much easier to connect to the slab and the walls with the help of an expanding cement (will prolong the service life of up to 80 years).

One of the most popular building materials for the construction of the walls is a seven. The stone is quite well, so the plaster requires a large consumption of the material. To reduce it almost twice, use expanding cement. It creates a monolithic durable coating and completely fills all the pores. Due to this, the surface becomes very durable and even strong mechanical shocks endure without visible damage. The use of expanding cement for foam concrete and slag blocks is allowed, but not so much relevant, since noticeable economy is not observed.

Cement expanding specifications and types

We will proceed to more detailed acquaintance with this material and consider what kind of modifications offers a modern market:

- waterproof expanding cement

- hyputoglin-grade expanding cement,

- expanding portland cement

- straggling cement

- plasticized expanding cement.

Waterproof cement is used as a waterproofing material. Among all the varieties, it has the smallest expansion, therefore it is ideal as outdoor plaster. Comprises:

- hinlacemic cement,

- gypsum

- high-base calcium aluminate.

This ensures a very high setting rate, the first phase begins after 4 minutes after applying the solution, the final setting occurs after 10 minutes. The expansion type is linear, which implies a gradual increase in the volume of the solution to the same value for a certain period of time (according to GOST no more than 1 percent in 24 hours). This property is particularly relevant for plaster, since the aligned layer will remain the smooth and after the final solidification of cement, which occurs after 18-26 hours, depending on the temperature (the hotter, the faster).

Gypsoglyzmic cement is also a waterproofer. In terms of its properties, it is similar to the previous form, but the main element of the mixture is a highly reduced clinker. This allows you to get a more durable coating. But, the process of complete solidification takes from 70 to 85 hours. It is worth such cement more than waterproof, so it is not relevant to everyday life.

Expanding portland cement or RPC is obtained by grinding clinker portland cement and gypsum. Adding a blast slag provides superplicability of the material that it is beneficial to use to create monolithic reinforced concrete structures. The material is expanding only in a wet environment, while direct irrigation is not allowed. Ideally, you need to create a steam room, but in practice is limited to one-time steaming. This cement is completely becoming 65-80 hours (in the conditions of the steam 30-35). When working, it is important to consider that the type of expansion is not linear, therefore, as the finishing material cannot be used.

The straining cement or NC was created specifically for repair and restoration of reinforced concrete structures. It includes:

- portland cement - 70-75%,

- cylinder cement - 15-20%,

- gypsum - 10%.

This composition makes work with the material as comfortable as possible. As a catalyst used ordinary water. After applying the solution, it is watered and after 30-35 minutes do the finishing layer. After 4 hours, cement is finally collected and absorbs moisture, after which it starts expanding and binding reinforced concrete. Finally hardens after 70 hours. Such cement increases the strength of reinforced concrete structures by two times. Therefore, in industry it is used to finish water pipes and water warehouses. In everyday life, the use of the material is unnecessary, since the loads on which it is designed is impossible under normal conditions.

The newest type of expanding binding materials is a plasticized cement. It consists of an ordinary portland cement in which plasticizing elements are introduced, usually concentrates of sulfite-alcohol bell. This material, in contrast to the other analogs, has not only increased strength, but also plasticity, which allows you to use it to create working surfaces (roads, messages, pouring under the floor, etc.). As a rule, it is not used in its pure form, but mixed with concrete or ordinary cement. Linear expansion type.

Manufacturers expanding cements

There are quite a lot of firms offering expanding cement. Buy it, however, quite difficult. This is due to two factors: the reluctance of large manufacturers to work with the retail buyer and the presence of a large number of handicraft plants producing products that do not correspond to generally accepted standards. Therefore, experts analyzed the market and accounted for product rating, which is ideal for domestic use:

- "Pashi Metallurgical Cement Plant".

- "Perm Metallurgical Cement Plant".

- "Mordovcement".

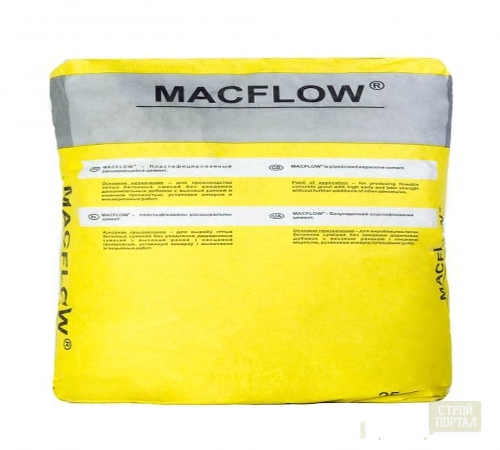

- MacFlow.

The Pashian plant specializes in plasterland cement. He became one of the first in Russia, who actively began issuing this product, so it is represented by the widest network of distributors. The cost is from 1,400 rubles per 50 kg.

The Perm plant is one of the largest cement enterprises, therefore it offers a fairly large range of goods and their various modifications. The cost of products from 16,000 rubles per ton.

Mordovcement is inferior in the volume of products produced by the first two industrial giants, nevertheless, it offers a very high-quality product at a fairly adequate price, from 3000 rubles. Specializing specifically on expanding portland cement.

Plasticized cements in Russia are not manufactured (at large enterprises). This is due to their high-cost and extremely narrow specificity. Therefore, products are presented exclusively by the MacFlow brand. Since 2013, the name has been changed to Master Emaco (products with the name MacFlow was released until 2013, therefore, for a maximum of 2020, the shelf life of 8 years).

Master Emaco brand is part of the American Corporation Basf The Chemical Company, the world's largest manufacturer of modernized building materials. It is worth noting that the plasticized cement Master Emaco can fully replace the usual one, while its characteristics are significantly higher. Nevertheless, the price is from 70 rubles. per kilogram is high enough.

Advice: It is important to understand that in the domestic use of the load at times lower than on industrial facilities or in public areas, therefore, the expediency of using expanding cements is a very controversial issue. If we are talking about repairs in the apartment or construction of a private house, it is much more practical to make your own mixture, which, although it will not expand, however, in terms of quality, it will not give up newcomer analogues. It is prepared as follows: 3 parts of cement, 2 pieces of sand, 1 piece of gypsum, 1 piece of glue for tile. The only one, such a solution becomes very fast, so it is necessary to make a portion for 30-40 minutes of work.