Bar rack do it yourself Interior items

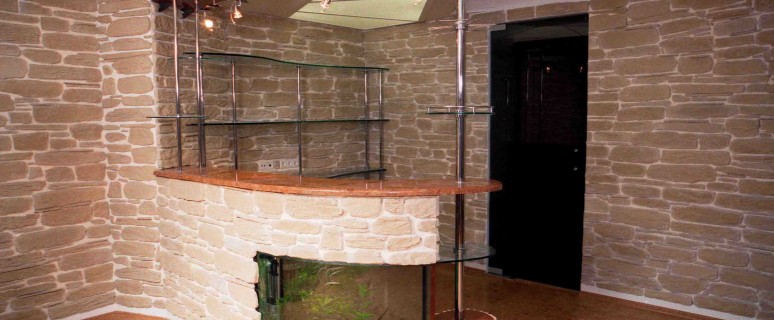

The sign of the stylish interior and the exclusive is the presence of a bar stand in the room. It can be located in the kitchen, in the lobby or hall. Make a bar rack with your own hands is not difficult. The process does not require special efforts or financial costs for materials.

Content

In order to make the bar rack with your own hands, you need to start the rack scheme to begin, decide on it with sizes and materials. Materials used for bar racks: chipboard, dvp, plywood, drywall, wood, plastic, metal, brick, etc. Choose an acceptable option, a bar rack shapes can be found with the photo. More detailed instructions for the manufacture of bar racks do it yourself, there is a video.

Used materials for bar racks

- A good material is plastic. Easy and not expensive material, very convenient in processing. A small minus of such a material is low strength. Plus - the ease of construction and the resistance of the color gamut. Plastic over time does not fade and will not be pale.

- Laminated chipboard - more durable material, although it is slightly higher in price and more difficult in processing. But its color scheme is much wider. You can pick up the chipboard plate from the imitation of the tree of various breeds to multi-colored marble.

- The drywall makes the barn racks of a wide variety of shapes and styles from traditional to Hajkin. Such racks are painted in any harmonizing with the interior of the room color.

- More expensive and very solid bar racks are made of various wood species. For the manufacture and assembly of a wooden bar counter, you need to have elementary carpentry skills.

Table top manufacturing process

The main part of the bar counter is a tabletop. She immediately rushes into the eyes and sets the tone of the whole design. The tabletop stove should be durable, resistant to mechanical wear and beautiful. It can be made independently or buy ready-made in the store.

- For the tabletop, it may well be a plate of chipboard. Electric jigsaw cuts out the tabletop of the required form. In places trimming, the surface of the slab is cleaned and decorated with the end ribbon.

- The end ribbon is sold in all building stores and has a large color spectrum. It glues with a household iron. Tape residues are removed by mounting knife.

- If you do not satisfy the color of the stove for the table top, it can be changed, saving the surface with a self-adhesive film of suitable color.

Types of base Bar racks

- Racks differ in the number of shelves at the base. From one shelf, which is the table top to a multi-filling structure.

- At the location and attachment. Bar rack can stand independently or the end, fasten to the wall or other interior items, which provide reliable support and stability.

- There are racks multilevel, in the form of a ladder and classic. The height of the latter is usually done at least 1.5 meters.

Bar rack base

Base of bricks

- From the brick and cement mortar there is a base in the form of a parallelepiped. Brick better use red facing. Such a rack can stand separately, without contacting other objects, and refers to the American type of "Island" racks.

- When using another building brick - the base must be placed. Stands of this type are characterized by a lot of weight and stability.

- A massive marble or thick wooden plate is suitable as a tabletop.

Other types of foundations

- The base construction under the tabletop can be made from a bar 4x4 cm or a profiled metal corner with a width of the shelf 4- 5 cm and steel thickness from 3 mm.

- The steel corner is welded into the design in the form of parallelepiped, they are simply welded fasteners for the rack shelves.

- The base is pretty and painted. The scenery of such a basis can be carried out by plastic, clapboard, chipboard, wooden panels or any other suitable finishing material.

- A similar form is based on a bar. It is desirable to strengthen the finished design for the fortress and fix the end side of the wall or firmly worth the interior item.

- A large plus base of this type is a small weight and the possibility of fastening not only to the wall, but also to the floor, which gives them greater stability. The tabletop for such racks should not be too massive and heavy. It is quite suitable for a tabletop of laminated chipboard.

Bar rack made of wood

- For the construction of a wooden rack, you need to have elementary carpentry skills. First, sketch the scheme of the future bar counter.

- For installation, you will need a lap board, a bar, you can use carved bales and a wooden table top for the decor.

- The tabletop of the necessary shape and size can be ordered in a joinery workshop. Wood should be dry and without a large number of bitch. The tabletop from a solid wooden array is not recommended, as it can twist. It is better to make it veneered on glue.

- For countertops choose good wood species, such as oak, nut, beech, cherry or tees. Bar rack can be used cheaper wood - coniferous rocks, a lamp or aspen.

- The base of the bar rack made from other rocks is thoroughly polished by sandpaper, the flaws are flawed with a spanking mass for wood and rub.

- To create one color scheme, the base of the bar rack is impregnated with a veil, and then the entire bar stand is lacquered.

New comments

Add a comment

To send a comment you need authorize.

I bought myself windowsill home from some kind of wonderful unknown stone in the world of artificial hanex. I assure you, now I'm gratifying to buy not brand things !!!!!