How to make a gate yourself. Useful tips, photos and video instructions Plot.

The wicket does not only perform the practical function of entering the courtyard, but also is an important element of the decor. Beautiful gate decorates entrance to the plot, and says a lot about his owner. If you have a desire to decorate the fence at home with the original entrance, we will tell you how to make a gate yourself.

Content

Determining the place and size of the wicket, select the material suitable for it. It may be a tree, steel sheet, forged iron, professional flooring or any other material suitable for the manufacture of wicket and harmonizing with a fence. About how to make a gate in the fence, read below. A person who can keep the hammer and hacksaw in his hands, make a wicket with his own hands - not at all difficult.

Wooden wicket for giving

The easiest way to make a wicket out of the tree. For this you do not need special material costs and skills. Enough to take a few boards or staketing and handful of nails. Such a gate will perfectly fit into the old stone fence or a female fence.

- In the width of the opening, the support racks are installed. It can be iron columns or a wooden timing with a cross section from 10x10 cm. Racks are driven into the ground in pre-dug holes. For reliability, the base falls asleep with sand with rubble, tamper and poured concrete. Wooden reference racks at the bottom are pre-treated with rotting agents.

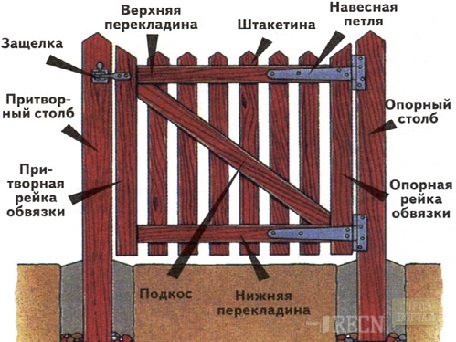

- In the size of the input opening, the rectangular frame of the bar is laid. Its thickness can be from 3x3 cm and more. A facing board is styled on the frame. You can make a solid array or fill the sparse nearby. From the back side of the wicket from the stakenikovka rail, they feed the fixing bar in the form of the Latin letter of Zet.

- It remains to paint the gate, attach a loop, handles and hang it in your place. The loop is better to choose durable, by type of garage. Such hinges will serve much longer.

- If you wish, you can fantasize and decorate the wicket unusual decor. Beautiful carved panels or wrought elements are used, but the main design is made in the method described.

Making frame (frame) for wicket from metal

Frame or frame made of metal base, suitable for all types of metal wickets. This requires tools, welding and skills in metal processing.

Tools and materials:

- Cellular machine (turbine or Bulgarian)

- Welding machine (electrical or gas)

- Screwdriver

- Electric drill

- Shovel, sledgehammer, Waterpas (level)

- Metal tube or 5mm thick profile.

- Install support columns. It can be a metal tube, a channel, brand or corner. Supports are driven into the ground and the base is concreted. Sometimes the upper transverse mount is welded to give stiffness of the structure.

- The opening of the opening makes the frame of the wicket. Usually it uses a corner with a shelf from 5 cm and a metal thickness from 3 mm. The rectangular frame is connected along the corners of welding, the loops are welded to the base and the support columns. To give a frame of rigidity two - three transverse strips.

Assembling wicket from professional flooring

Professional flooring - convenient for processing, light and not expensive material. The wicket from metal products looks good in combination with a fence or gate from the same material. It is better to acquire colored cornet painted in the factory.

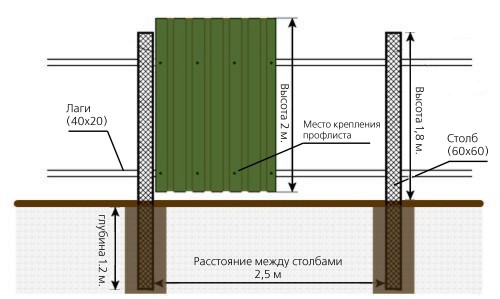

- The calculation of the necessary materials on the dimensions is made. The optimal height of the wicket from metal photographs is 2 meters, the width varies in the area of \u200b\u200bone meter. If the height is set by the standard sheet size of the sheets, then the width is adjusted along the bottom wave of the profile.

- For the specified size, two recesses of 1.5 meters for side racks are rooted. Pipes or other profile material intended for the racks is planned, processed by the anti-corrosion composition and is covered with paint. The installed racks are poured with concrete.

- The collected and welded frame - cleaned from rust and degreases. The surface should turn out to be smooth, without gaps and cracks. After stripping and degreasing, primer and painting are made.

- In the size of the finished frame of gate, with the help of a corner-glare machine from metal products, the facade canvas for the wicket is cut. The mounting of the canvase is made by self-proofs or rivets.

- At the final stage, a handle is installed, and the loops are welded. To install the lock, additional mounting shelves are welded in size of the lock. The finished wicket is hanging out on the support columns and in terms of the level of retractable riggers in one of the support pillars of the turbine, the locking pocket is cut.

Other metal wickets

The simplest shape of the wicket from the metal, usually used in the country - the curvature cross is welded on the frame to the frame.

- As a facial web, you can use a steel rolled sheet with a thickness of 2 mm. It is easy to carve it to the size of the carcass a corner car with a disk for metal cutting. The canvas is fastened with welding around the perimeter or spinning screws for metal. The surface can be painted or screwed decorative elements.

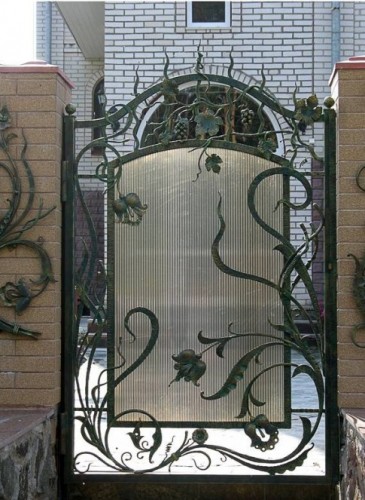

- Worn wickets are very beautiful. Decorative elements, including metal leaves, flowers, intertwined in different combinations and create a very beautiful composition. Step-by-step instructions on how to make a wrought wicket with your own hands, is in the video.