Household Submersible Centrifugal Pumps Useful advice,Plumbing

Very often, dacms and country house owners face the problem of the absence of a centralized water supply system. In this case, it is impossible to exist without it, because Water is necessary for the needs of people, and for watering plants. In this situation, the use of a pump can be an excellent way out, and its choice will depend on how you will take water from. If from deep sources, such as well, well, etc., then you should stay on the submersible pump. Such devices are different, but the most optimal among them are centrifugal - they are suitable for most of the wells.

Content

Pump centrifugal submersible: device and work principle

Such a device is equipped with special wheels, which rotate at a certain speed, due to which centrifugal forces that move water occur.

The device of the submersible centrifugal pump is: the device includes one or more steps, from the number of water lifting the height, i.e. head. Single-step devices are the most simple and common, but they are not very good because it is not capable of creating a strong stream. Much more functional multistage pumps. Each of the steps creates a specific pressure, which ultimately is summed up.

The impeller can be different diameter. This parameter determines the pump performance, in other words, how much water it is capable of submitting for a certain period of time.

Such devices are very reliable and produced. In their production, they usually use the highest quality and wear-resistant materials. In those sites where the greatest friction occur, a special spraying is made or inserts from graphite.

Advantages of using submersible centrifugal pumps:

- quality and reliability;

- long service life;

- high efficiency;

- create a good pressure;

- the flow of water is not interrupted;

- can feed water to a large height;

- easy to use and maintenance;

- along with all the advantages have a relatively low cost.

But this device has a significant disadvantage - the ability to pump only clean water. All varieties and models of submersible centrifugal pumps, regardless of their parameters, inevitably fail in operation in a dirty medium, because Pollution clocked their hydraulic system and cause imbalance of the imbalance.

Types of centrifugal submersible pumps

Centrifugal submersible pumps are classified as follows:

1. By the number of steps:

- single-stage;

- multistage.

2. According to the degree of pressure:

- low;

- the average;

- high.

3. According to the method of water supply to the impeller:

- one-sided feed;

- double-sided feed.

4. On the position occupied by the shaft:

- horizontal;

- vertical.

5. According to the hull connector:

- horizontal;

- vertical.

6. According to the water supply option from the impeller to a special channel:

- spiral;

- turbine.

7. By speed:

- slow;

- normal;

- fast.

8. According to the connection with the electric motor:

- by means of the drive;

- by couplings.

Domestic submersible centrifugal pumps differ from industrial in their sizes and power. They are not intended to perform large volumes of work, and are designed to ensure the needs of a small object.

Independent installation of the submersible pump

Of course, it is best if professionals do, but if you do not have free tools, then this task is subject to independent execution. The installation process looks like this:

- prepare the pump, brackets, cable, pipe, couplings, cable, and if the water is needed, in order to water the plants in the yard of the house, then the hose;

- attach the pipe or hose to the pump;

- attach the cable;

- to eliminate the risk of damage or complete output of the pump, it is strictly forbidden to move or lift it, keeping it for a cable or hose;

- in order to move the device safely, an insurance cable should be purchased in advance;

- now lower the pump, check it and make a trial launch;

- after an hour of operation, turn off the device for a while to give him a breather.

The next three days carefully watch the pump work. If no malfunction is detected after this time, you can start exploiting it.

Repair of centrifugal submersible pumps

If your pump has failed, you need to carefully examine, because some faults can be eliminated by yourself without spending on this extra money.

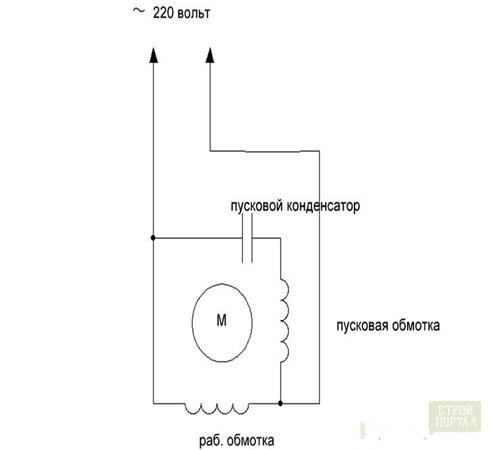

The pump engine is usually filled with mineral oil, which cools the windings and provides additional insulation. In the domestic device, it has one phase and two windings, the first of which is working, the second is launched. The launch chain includes a non-polar capacitor. Its container is 10-40 μF. The electric motor has one phase and is asynchronous.

- If a malfunction occurs, the first thing should be checked how freely the motor shaft is rotated, equipped with an impeller. It often happens so that foreign objects that have fallen into the snail are jammed. If you do not intervene on time, the engine stator winding can burn.

- If everything is fine with the shaft, and it rotates without interference, then collect the bottom of the engine and disassemble the top. In this case, the pump must be in a vertical position, otherwise the oil flows out of the housing.

- Unscrew the bolts fixing the lid and remove it. You will see the wires and the starting condenser. When repairing a centrifugal submersible pump, the scheme below will help better imagine its device.

- Take the multimeter and measure the resistance of the engine windings. In the working winding, this parameter should be 10-15 ohms, at the start-up - 35-40 Ohm. If the measuring device shows the resistance value of equal infinity, it means that the winding break occurs. If the resistance index is extremely small, it means that there has been an internal intervatite closure in the windings.

- When a malfunction is detected, if possible, eliminate it yourself. Replace the faulty item, and the pump will work again.

From which the cost of the pump depends

The centrifugal submersible pump, the price of which depends on its technical capabilities and the manufacturer, can be purchased either in online stores, or at the points of sale of goods for home and repair. Some prefer to contact the manufacturer itself, immediately concluding an agreement with them for service.

Today's market is saturated with devices of both domestic and foreign production. At the moment, domestic producers in the quality of products are not inferior to imported, but they ask for their goods much less. Therefore, the pumps of Russian firms are more preferred. In addition, their repair and maintenance cost much cheaper, and parts can be purchased at any specialized store if necessary.

Keep in mind by buying a centrifugal submersible pump: the cost of the domestic instrument ranges from 2500 to 6000 rubles, and the cost of imported, which is no better, sometimes reaches 20,000 rubles.