How to make a house for a well do it yourself Useful advice,Plot.

Well, as a technical structure consists of several parts. One of these parts of the well is its ground part, called the headband. The headguard of the well can be arranged as an invisible design underground. Sometimes this may be due to the peculiarities of the site or other circumstances. But usually this part of the well, in addition to its main function - protection of water from pollution, performs a decorative role. For simplicity of understanding, what is being spent, the headband is more often called the house for the well. This is all the more relevant, since the arrangement of the wellhead is in the form of a house is an element of the landscape design of the site.

Content

Now there is a huge selection of ready-made houses for wells, but the cost of such products comes to the idea of \u200b\u200bindependently manufactured it and it is quite forces to everyone. After examining the proposed step-by-step instructions on how to make a house for a well, you can not doubt the positive result.

PURPOSE OF THE DOMIC FOR THE WELD

As mentioned above, the main function of the house for the well is protective. Such an arrangement of the wellguard of the well protects water from:

- Getting trash and foreign objects, which are dust, leaves, grass, branches, insects, and so on.

- The impact of direct sunlight on the water, thereby worsening its quality.

- Finding various types of precipitation, such as rain, snow, hail, and so on, also polluting water in the well.

- Penetration of chemicals used to treat plant plantings on the site.

- Freezing in winter.

In addition, the house for the well is:

- The barrier from falling into it children and pets.

- Compound part of the water supply device.

- Decorative element of the decoration of the site.

How to make a house for a well. Selection of material

Often the choice of material for the well house depends on the preferences of the area owners. But if such preferences are not clearly defined or means for arranging the well are limited, then you can use the advice here.

Courtyard for a well

- Stone is very beautiful, durable, but at the same time and quite expensive material. Although it is possible to reduce this design, too, if it is not a solid stone when building it, but only a stone or imitation under stone.

- Natural stone used in the construction of a well house, it is necessary to use flat or slightly curved. Bound stone is best suitable - it is the wrong shape of sandstone slices, limestone or granite.

- When choosing as a building material of bricks, the red brick-Zheleznyak is better suitable, which has increased strength and water resistance.

Tree for a well

Wooden housework designs for the well can also be both from a solid log (timber) and made from wooden frame and covered with various materials (boards, siding, panels, block mobile, etc.).

Metal Well House

Metal material for the construction of a well house is mainly used to build a frame. It can be a metal corner or profile tube, preferably galvanized. Metal tile, iron galvanized sheet, or decorative decoration with metal forged openwork elements can be used in the decoration.

There is one rule that helps you choose a material and style for the construction of a well house. If the well is located next to the already built structures on the plot or their style and finishing materials are defined, the well is best done in a single architectural ensemble. In addition, in this case it will be possible to use materials that remain from the construction of a house or other structure.

How to make a house for a well. Open or closed design

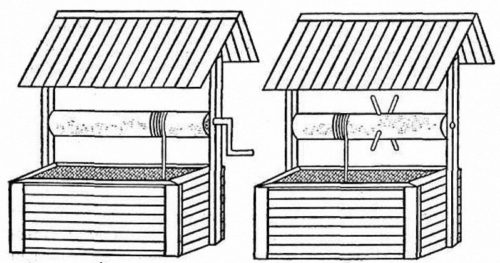

There are two types of house designs for a well. It is open and closed.

- An open type of construction is a canopy with an externally open waterway mechanism and a lid at the mouth of the well.

- The closed type of construction provides for a fully separated by the roof and walls from the external environment of the space above the well with a water supply mechanism located inside such a structure. Access to the water lifting mechanism is carried out through a special hatch or door.

Basically, the design of the house design for the well depends on the functions for which it is calculated. If, for example, the climate in the area of \u200b\u200bfinding a plot with a well is warm, and there is no need to protect water from freezing or you do not plan to use the well in winter, then an open design is suitable. If necessary, protect well water from penetrating all possible unwanted effects, a closed well will be required. Also to choose from the design type of design and designer idea.

How to make a house for a well. Tools and Materials for Work

Depending on the materials used to arrange the wellgument, the list of necessary tools must be specified. The most common list of all the necessary looks as follows:

- Main building material. Tree (timber, logs, edged board, plywood, etc.). Stone (brick, foam concrete or aerated concrete, slag blocks, natural stone, finishing stone, etc.).

- Material for facing design (siding, panels, block mobile, etc.).

- Fasteners (nails, selflessness, metal corners, etc.).

- The chain or the cable of sufficient length for the water supply mechanism and a metal rod or pipe for the same design.

- Construction mixes for masonry and facing of a stone construction.

- Gravel, sand.

- Armature, when working with a stone.

- Material for waterproofing (tol, rubberoid or polyethylene film).

- Roofing material for the roof (canopy).

- Bar for vertical racks of water supply mechanism with a long 2 m and a diameter of 150-200 mm, as well as a log diameter of 180-200 mm, a length of 1.2-1.5 m for the gate drum.

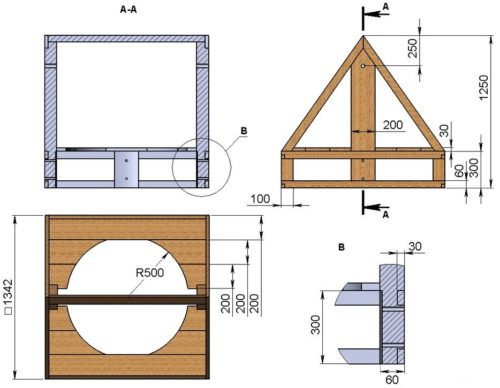

- Brucks for a rapid roof system 75 × 50 mm or 50 × 50 mm.

- Boards with a thickness of 40 mm and a width of 120-150 mm.

- Tool to work with wood:

• Woodworking machine or electrical plans (handwritten);

• disk saw and / or electric jigsaw;

• wood hacksaw;

• Hammer, Passatia, screwdriver, and so on. - Stone tool:

• chisel and hammer;

• hammer-korchka to cut a whole brick on various parts (halves, quarters) and their clothes;

• Mop to fill seams with solution and smoothing them;

• Construction workshop, falcon for thick and liquid mortar.

• Buchard - a hammer with a tooth at the ends for applying notches to the surface for the purposes of better clutch of the solution with the surface;

• plastering blade, brush and brush brush;

• Construction mixer for kneading solutions. - Metal tool:

• welding machine;

• Bulgarian with a set of various assignations. - Measuring tools (roulette, construction level, square, etc.).

- Construction pencil.

- Fittings (loops, handles, latches, etc.).

- Protection for body, eyes and arms (masks, glasses, gloves, etc.).

Building a house for a well

In independence from the material chosen for the construction of a well house, it is necessary to take into account the following general requirements for the design being created:

- Since in the design of a house for a well, an water-lifting mechanism must be provided, the construction must be durable and withstand all operational loads.

- Independence on the type of construction (open or closed), the well house must have a cover, overlapping access to water for its preservation and prevent accidents with children and domestic animals.

- In the design of the house for a well, an inlet for the watering hose must be provided so that the well cover remains open at all time watering the soil on the site.

- With the average air temperature in winter, in the area of \u200b\u200bthe location of the site with the well, below -18 ° C it is necessary to provide insulation of the structure (including open species).

Building a waterway mechanism

Before proceeding to the construction of a home house directly, it is necessary to install a mechanism for lifting water. This mechanism will be an integral part of the well house.

The most common mechanism for lifting water from the well, which is with a well house one is a gate.

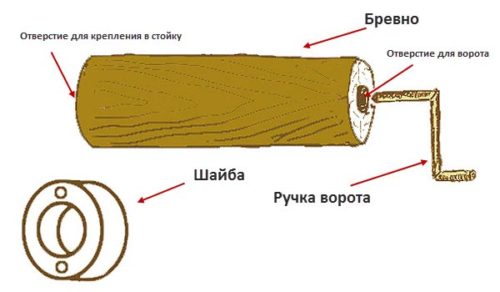

The gate is a log (drum) with a diameter of 180-200 mm and a length corresponding to the width of the construction of a well house. The gate mechanism is built in the following order:

- Initially, the log along its longitudinal axis, is inserted a steel rod or tube of 20 mm diameter (sometimes in the middle of square cross-section and circular at the ends, so that it is not turned inside the timber during its rotation). For greater strength retention of the rod in the drum hole along the longitudinal axis of a log is made somewhat smaller diameter than the diameter of the rod, and then a wooden hammer shank is driven into the log. Before you drive a rod into the timber, the hole must be treated with a hydrophobic composition and antiseptic.

- By the end walls of the well are attached uprights. Wooden rack represent logs or timber of different cross-section with a height of 2 m and a diameter of 150-200 mm. To impart greater stability of the lower ends of struts can be dug into the soil to a depth of 5 to 10 cm. Also, to impart strength strut designs can rest against a foundation pit or mount them together with the substrate. Material for the manufacture of racks may be selected arbitrary. It may be, except wood, brick, stone or metal. Racks can be decoratively arrange wood carving, hammering or decorative masonry. If the sump house is made of stone, the rack can be supported on reinforced belt in its upper part. Wood structure allows to rely on the support pillars countertop.

- The strut bearings mounted with an inner diameter of 20 mm corresponding to the diameter of the rod in the drum. The bearings can be lubricated for better glide.

- The bearings are inserted into the ends of the shaft of the drum.

- In order to rotate the drum to its shaft, with one or both ends of the handle is attached to a gate (sometimes in the form of a steering wheel and the like).

- In the center of the drum must be reliable fastening to attach one end of a chain or metal cable.

- At the opposite end of the chain or rope attached bucket (metal or wood).

- The upper ends of struts attached canopy or roof. It can be a lean-or gable (uniform or non-uniform).

Building stone

During the construction of houses for the well entirely of stone used the same technology, as well as in the construction of a stone house with reinforced waterproofing.

Works are carried out in the following order:

- Concrete ring projecting above the ground, it is necessary to cut grinder to the desired level, taking into account the height of the foundation.

- Perform waterproofing between the foundation and elevated walls. It must be performed qualitatively, since the humidity in the well is higher than in atmospheric air. For what:

• Remove the soil from the outer side of the concrete ring to a depth of 10-15 cm;

• the liberated surface to be dissolved and tightly tamped;

• coat on top rubreaded, tale or polyethylene film;

• Fly with gravel or coarse-gravel sand and good tamper.

- Around the well to lay a foundation from concrete. In order for the concrete mixture to be better grabbed and solid, and was also more durable, various additives and additives are used. These are plasticizers and liquid additives. For example, plasticizers such as "KeemNT L10", in an amount of 1-2% of the total mass of cement, prevent the foundation shrinkage and increases its strength. The same properties give the concrete mixture and liquid additives for example, "ADDITIV FOR EXPANDER", added in the ratio of 0.7-1% of the entire mass of cement. Also, fittings from the rods of various diameters can also be used to enhance the strength of the foundation.

- Next, walls from the selected material are erected on the foundation. Masonry is performed in 1/2 slag block or one brick with sutures.

Also laying the walls can be immediately finishing a stone:

- For the preparation of cement mortar and concrete, it is best to use pure river sand and portland cement. As concrete aggregate, gravel or crushed stone from rocks is used.

- When preparing a cement solution, the sand and cement ratio is calculated based on the instructions on the cement packaging. Usually, this relationship is 1 part of the cement 2-3 of the sand of the sand, which is filled with water and is thoroughly mixed. The solution must be used no later than 1 hour after its preparation, otherwise it will freeze.

- Before masonry walls from red brick, it is pre-mixed with water.

- The upper part of the masonry is strengthened with the belt with reinforcement.

- If the masonry was performed not from the finishing material, then the exterior decoration of the walls of the well can be performed. Finishing foam / aerated concrete or hollow brick contributes to good insulation, which avoids the winter formation on the walls of the well due to the freezing of water condensate.

Facing stone

To reduce the construction, but give it a type of stone facilities, use stone cladding. You can facing both a concrete ring, and any design made from various materials under the cladding of various configurations.

Works are carried out in the following order:

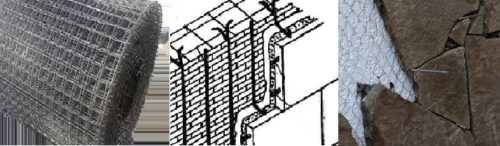

- On the surface of the structure made under facing stone or concrete ring must be attached welded grid (masonry) with a mesh size of 50 mm and 3 mm thick wire.

- To attach the mesh to the concrete must in the outer ring surface of the ring drill holes 4-6 mm in diameter and fasten them anchors. Anchors need to prepare in advance. They represent a trim metal wire of 4-6 mm diameter with a 90 ° curved ends. Anchor length must be such that while being supported in a concrete ring he performed at 5-10 mm. Then these anchors to attach the wire mesh wrapped her concrete ring completely.

- Further to this base by means of special mixtures attach any kinds of hard facing various stone.

Construction of wood

For the construction of the well house made of wood, you can use the log or timber, left over from the construction of a house or a bath. Construction Technology The wall is the same as the walls of the house (only small size). Beams formed in the framework of the well dimensions and connected to each other. For the rest, all the actions are repeated, as well as to build a house out of stone.

Works are carried out in the following order:

- Create a drawing frame future house.

- Prepare the board and board, treating them with antiseptic.

- To saw boards and bars in size according to the drawing.

- Before mounting the frame on the well is necessary to cover the mouth of the plastic film to avoid being hit by debris.

- Collect the frame on the supporting racks water-lifting mechanism.

- Sheathing frame boards.

- Attach to design cladding, roofing, door (hatch) and the necessary accessories.

Facing wood

Process wood veneer is a wood frame construction of the concrete around the ring mounts thereon any fabric. This may be a siding, blockhouse board or roofing material.

Works are carried out in the following order:

- Tree built for the frame and the lining is pre-processed antiseptic.

- Made boards for the four sides of the casing.

- Solid necessary to insulate the inside by means of foam or polyurethane foam.

- On the concrete ring at points of contact with the frame are mounted four pieces of wood.

- On the vertical bars with screws to attach the panels and align them on the horizontal level of self-tapping screws to pull the corners.

- Clearance fill arbolita (mixture with sawdust solution).

- Now the outer side panels can attach the selected finishing material and ornamental decorations.