How to make a roof from a professional flooring with your own hands Construction

Like any construction, the roofing device from the corrugated floor has its own technological card. The sequential execution of which guarantees high-quality operation and long service life of the roof.

Content

The main elements of the roof of the corrugated

The profiled sheet is manufactured using cold rolling technology. To do this, apply galvanized steel. At the last stage of production, the sheet is profiled, i.e. He gives a certain form. There are several profile varieties, but according to most experts for the roof, the wave option is best suited.

The wave profile showed itself in the regions with the most severe climate. The structure of the surface allows you to unhindered to remove rain precipitations and snow, evenly distributing the load over the entire surface of the roof.

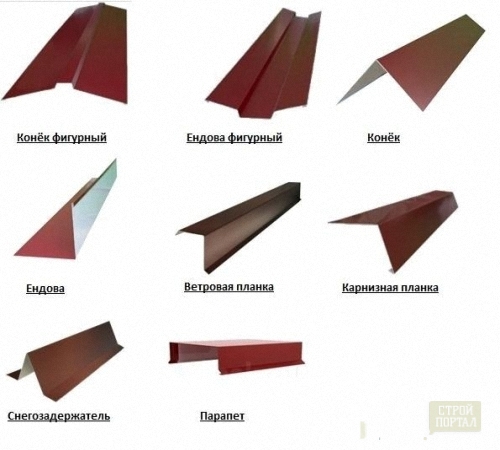

In addition to the sheets themselves, the following elements of the roof from the professional flooring will be needed:

- batch figure

- endow figured,

- bump

- endova,

- wind strap

- cornice bar

- snowman,

- parapet.

All these elements can be bought in a specialized store or order on metal bond. In the first case, the cost of goods will be more expensive, but you will get the exact number of parts and sheets of the appropriate size. In the second - on the face saving funds, but there may be problems with the package.

Tool

In order to make the roof from the corrugated floor it will be necessary:

- roofing staircase

- screwdriver with a set of "hexagons",

- metal scissors,

- bulgarian,

- insurance cable.

The staircase will be needed when the first row of professional flooring is installed. Lovers slippery, so to create supports use roofing staircase.

It is necessary to mount the leaf to the extender every 20 cm. In the manual cut, the metal can be screwed, but considering the scope of work, without a screwdriver it is not necessary.

Complete and customized parts to the desired size is easiest way on Earth with the help of a grinder. But, sometimes the problem occurs after the element is fixed. In this case, it is more convenient to use scissors for metal.

A cable may be any rope. One of his end is tied around the body, the other is securely fixed behind the roof support.

Choosing a type of roof

Consider the technology of the roofing device from the corrugated. First of all, calculate the correct angle of inclination. This value depends on the following factors:

- wind power

- the level of atmospheric precipitation.

A strong wind not only strive to tear off the sheets from the branch, but also strikes the roof. Therefore, in the windy regions it is not recommended to make a bias more than 30 degrees. The minimum bias of the roof from the corrugated floor is 23 degrees.

If the wind is not, but overpowered atmospheric precipitates, then you can safely do the angle of inclination from 45 or more degrees.

In the regions, with frequent rains and strong winds there is a solution. As a rule, such atmospheric regime is observed in coastal territories. When building a house, it is necessary to take into account the location relative to the water. The strongest winds blow either from the sea or at sea. Thus, in these directions make end parts. The roof is building a two-tie with a bias of 35-40 degrees.

Regardless of the angle of inclination, the following types of roof are distinguished:

- flat

- single,

- two-screw without a attic

- two-batch with a attic.

Flat roofing from the professional flooring is not allowed. This is due to the fact that this material performs its task only at a certain angle. The flat roof of the profiled sheet will begin to leak. At the same time, after the first winter, the sheets will be deformed and are not suitable for further use.

Single roofing from the corrugated floor is usually used over the patio or verandas. Also, a single-piece roof is installed above the structures, which are close to the main home. In regions with abundant snow, single-table roofs are not recommended. They delay snow, and under his weight, profiled sheets are deformed. This leads to the flow of the roof.

Double roofs without a attic are used for the roof of separately worthwhile buildings. They are reliable and fully protected from leakage in all weather conditions.

Most builders converge on the fact that the roof should be performed by monolith. The more connections, the higher the likelihood that they will begin to leak. Considering that from the place of the pumping, to the spot on the ceiling, the water can go a long way, it is very difficult to find and fix the defect.

Therefore, during the construction of residential buildings, a two-tie roof is used with a tykomome total house. First, it allows you to make a monolithic roof, and secondly the attic is easy to convert into the attic, a game room or an office.

Installation of the roof of the corrugated

Installation of the roof from the professional flooring is divided into the following steps:

- frame preparation,

- extending

- hydro and paro insulation,

- installation of profiled sheets,

- installation of additional elements,

- insulation of fasteners.

Whatever the roof type you have chosen, the frame is manufactured equally.

- On the perimeter of the walls, install Mauerlat - a support beam for rafters.

- Take and fasten the rafters, depending on the selected angle of inclination. In the case of a two-tie roof, the rafter will be in the form of an equilibrium triangle, in the case of a single-table - a rectangular triangle.

- Install the rafter supports, link the rafted by the Rigel - crossbar between the rafters.

The rafters must be set at a minimum at a distance of 50 cm from each other.

The extension under the profiled sheet should be thick. The distance between the boards is no more than 5 cm. Explains from top to bottom.

Parosolation is attached to the inside of the pitch with the help of a construction stiplars. Waterproofing is mounted in the same way, but from the outside.

After performing the preparatory complex of work, go to the mounting of the roof from the corrugated floor.

- Install a horse.

- To start a profiled sheet to a depth of 3 cm.

- Attach the sheet, except for the last span from the bottom and from the side that the skate continues. The mount is carried out every 20 cm, both diagonally and vertically.

- Take the first sheet next to the depth of at least 5 cm or one wave.

- Finally secure the first sheet. Start securing the second. The side does not fix.

- Continue the procedure until the end of the skate, the same steps to perform on the other scap.

After the first row is completed, go to the second. Sheets are settled under the loose part of the professional flooring, and only after that fix. The depth of input is at least 15 cm or two waves. Sequentially performing these actions, finish covering the roof.

Now you need to install funds and snowstores. Endovans are installed in places of convergence of sheets of professional flooring, if the roof has several slopes and angles inside the design.

Snowbornels are installed so that the layers do not fall on the head, but they went away with uniform small batches. Mount them are needed in a chess order at a distance of 1.5-2 m from each other. If there is no heavy snowfall in your region, then you do not need to install this item.

Parapets and wind strips are set if the roof design has certain architectural elements. In modern construction, parapets do not apply.

In order to avoid repairing the roof of a corrugated floor, it is necessary to insulate the places of fasteners. This uses either bitumen bases or silicone. It is necessary to treat every screw. As a result, the roof will be reliably protected from any weather in several decades.