Warming the foundation by polystyrene foam with your own hands Construction

With the construction of the house, many are not thinking about the thermal insulation of the foundation, postponing this work for the future. But over time, the owners of houses understand that they made a mistake that influenced the characteristics of the carrier structure. It is possible to solve this problem by insulating the foundation by polystyrene foam.

Content

The insulation of the foundation is polystyrene foam. The need for work

The thermal insulation of the base of the house should be carried out for several reasons:

- Bagging the soil is accompanied by cracks. After absorbing moisture and the subsequent freezing in the cold time, the load on the foundation of up to 10 thousand kg / 1 m² appears. As a result, deformation processes arise.

- The formation of condensate on the inside of the foundation. This is due to different temperatures inside and outside the building. The difference in temperatures is the cause of the sputum of the walls where the fungus and mold appears.

- Cold floor. The foundation without thermal insulation material is directly in contact with the soil. This leads to essential heat loss. The floor in the house becomes cold literally within a few minutes.

Immediately the question arises: how best to insulate the foundation? You can do it both indoors and from the street. The maximum protection against the negative impact of external factors is achieved when the foundation is insulated with polystyrene foam outside.

The advantages of external heat insulation:

- freezing resistance (cold air does not penetrate the house);

- the presence of an additional barrier from the destructive effect of ravery and groundwater;

- protection of waterproofing material from mechanical load;

- incompetence of temperature differences;

- an increase in the basement period of the foundation (due to protection against frost-defrost cycles);

- shift point dew.

When insulating the base indoors, the foundation will remain unprotected for a wet environment, frost and ground soil. For this reason, it is resorted to the outer insulation of the foundation and the deficiency of the polystyrene foam.

Specifications of polystyrene foam

The positive qualities of the insulation include:

- low weight (load does not exceed 50 kg / m³);

- long service life (35-40 years);

- resistance to aggressive medium;

- low moisture absorption;

- versatility;

- good environmental properties;

- an acceptable price of insulation of the foundation by polystyrene foam.

The lack of thermal insulation material is higher thermal conductivity than basalt insulation. Also, some varieties of polystyrene foam have low compressive strength. Therefore, when acquiring a material should be paid attention to this.

The best solution will be the purchase and insulation of the foundation by extruded polystyrene foam, in the manufacture of which the foaming method is applied at high temperatures. The foaming components include carbon dioxide and freon. As a result of chemical reactions, it is obtained solid with a uniform structure of the insulation with granules 0.1-0.2 mm.

In addition to the above qualities, extruded expanded polystyrene is characterized by:

- low thermal conductivity;

- excellent compressive strength (up to 27 tons / m²);

- resistant to temperature differences;

- inconsistent processes of rotting and decomposition;

- solid period of operation (up to 50 years);

The material itself is produced and implemented in plates that have a length of 1.2 m and width of 0.6 m. The only difference is the thickness of the polystyrene, which varies in the range from 2 to 10 cm (2,3,5,6,8 and 10 cm). Some branded products are equipped with special locks by which the process of their installation is simplified.

The insulation of the foundation is polystyrene foam. Preparatory stage

The technology of insulation of the foundation is polystyrene foam includes several stages. At the initial stage, earthworks should be done. There is a digging of trenches around the perimeter of the building. Its width is 1.2-1.5 m, and the depth is the bottom point of the foundation.

In the area where rainy weather prevails, the drainage system at the sand pillow level is mandatory:

- at a distance of 0.5-0.6 m from the foundation around the perimeter of the building rushes a trench;

- on the bottom of the trench, the sand layer and rubble thick 5-8 cm thick;

- geotextile is laid on crushed stone, the extreme part of which should be on the top of the trench;

- on geotextile with a bias 2 cm / 1 m, drainage pipes are stacked with holes;

- pipes are covered with rubble.

After digging the trench, it is necessary to clear the foundation from dirt and disappearing concrete, as well as align the surface. Without an even base, it is impossible to qualitatively lay waterproofing material.

To align the walls of the foundation:

- at a distance of 1-1.2 m from each other throughout the height of the walls, perforated lighthouses are fixed;

- it is made a thick plaster solution (1 hour cement, 4 hours of sand, water);

- the solution is thrown by a trowel to the surface of the foundation with sharp movements from the bottom up;

- using the rule (is carried out on top of the wave-like movements), the excess solution is removed;

- after drying the first layer, the leveling layer is applied.

If there are drops over 25 mm before applying plaster on the foundation wall, the grid for reinforcement should be consolidated. After 2-3 weeks after plastering the surface, the insulation of the belt basement is proceeded by polystyrene foam.

The insulation of the foundation is polystyrene foam. Heat insulation work

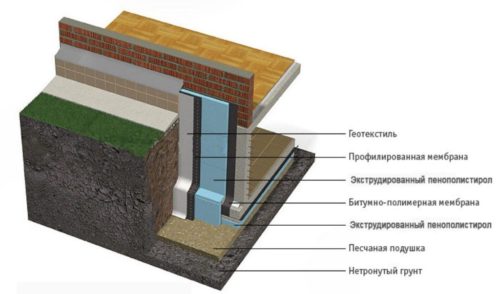

First conduct waterproofing surface. To do this, it is recommended to use two materials: bitumen mastic and rolled material (for example, a technonic). Mastics consumption is 0.6-1 kg / m². The need for a rolled material is calculated based on the foundation area.

Waterproofing foundation consists of the following steps:

- Cooking bitumen. If finished mastic is purchased, then it is necessary to simply unpack and apply to the surface. In the case of buying a dry bitumen, the material melts in the container with the addition of engine oil (5 liters of oil by 13-15 kg of bitumen). It is necessary to give a mixture of plasticity, so that in frosty days the coating will not crack.

- Bitumen. For this use roller. Material filled all pores and cracks. The coating thickness is 2-4 mm.

- Gluing technonic. After drying bitumen, the gas burner is melted by technonic sheets. Rolls are glued down up with smoothing. Under the material should not be bubbles. The sticking of the sheets is carried out with the allen at 10-15 cm. The jacks are processed by mastic.

Some "craftsmen" for the waterproofing of the foundation use only a rolled material. But this is not the best solution when insulating the foundation plate polystyrene foam. When moisture inserted under the techtonisc roll, the roll is almost always dug.

The insulation of the foundation involves the implementation of such works:

- fastening the first row of polystyrene plates;

- filling the slots between adjacent mounting foam plates;

- installation of the second row of insulation;

- plastering thermal insulation material;

- failure of the trench (after drying the plaster).

Installation work is carried out in the bottom direction upwards. The fastener of polystyrene foaming to the foundation is carried out using acrylic glue, which is applied to the glued side of the insulation in 5-6 points. The stove is pressed against the surface and is held for 1-2 minutes.

To fix the second row, the same glue is used. The slabs themselves are mounted with a displacement. The joints between the first next heat insulating material should be overlapped. The correct location in the vertical plane is checked using a level.

To ensure maximum reliability, you can use dowels with a length of 12 cm and a diameter of 1 cm. For fastening one plate, 4-5 dowels with a wide hat are enough. It is not recommended to use dowels at the bottom of the foundation, which will be covered with soil. You can damage waterproofing. Before screwing the dowels, the corresponding holes are made in the foundation and plates.

It is forbidden to glue insulation to preheated bitumen mastic. It is also fraught with a damage of waterproofing material. What will increase the cost of insulation of the foundation of the polystyrene foam.

The weakest place of foundation are corners. For this reason, they are insulated with an additional layer of material in a step of up to 1 m on each side of the corners.

As for the amount of polystyrene foam, then for high-quality thermal insulation of the foundation with a size of 0.4 m, the insulation is a thickness of 10 cm. The number of plates depends on the base area. For example, it is necessary to insulate the foundation with a height of 1.5 m around the perimeter of the house with a size of 6 * 4 m. The insulation area is 30 m² ((6 + 4 + 6 + 4) * 1.5).

The area of \u200b\u200bone plate of polystyrene is 0.72 m² (1.2 * 0.6). The minimum will need to purchase 42 plates (30: 0.72). Taking into account the laying of two rows and obtaining possible crosses of the material you need to buy 90-95 plates.

As a backfill, you can use not dug up the ground, but with sand or clay. This will also increase thermal insulation properties. At the final stage, a warm breakfast should be made. A concrete screed on a pre-prepared sand pillow and laid expanded polystyrene foaming poured under the bias from the foundation.

Fundament insulation technology extruded polystyrene foam on video: