Pipe benders and pipe bending machines: how to bend the pipe with your own hands Useful advice

Quite often, plumbing works in the apartment or the house have to do on their own. When carrying out such works, one of the problems is flexible pipes. If a gas burner is used to solve this task, the process goes back pretty quickly. If the operation with gas devices is not possible, it will be necessary to use a special device - pipe bending. Thanks to this simple device, you can easily cut a pipe of a small diameter at any angle. As a rule, household pipe bending are designed for pipes not more than 2. "

Content

The main advantage of using this device is that the pipe is bent without the formation of waves, which can lead to its rupture. Also, the bending of the pipe is obtained more accurate. Pipe bender is not much difficult to buy now. Building stores sell both mechanical and electrical models with a wide range of equipment. However, for one-time use, it makes no sense. Factory models of pipe bending machines are quite expensive, and buy them only for professional use. For repair, you can make pipe bender with your own person. On how to bend the pipe manually or with the help of pipe bending - further in the article.

Designs of pipe boobs

The principle of operation of manual tube bending is something similar to the manual hydraulic jack. Under the pressure of the fluid, which is inserted into the cylinder, the latter gives a lot of effort to the pipe point. Thanks to the supports on which the ends of the pipe are based, under the pressure of the hydraulic line, the bending of the pipe is carried out.

Manual pipe bending consists of several main parts:

- Hydraulic cylinder. It is this part that is responsible for the transfer of effort to the pipe. In the cylinder case there is a revision hole for controlling the oil level and its topping if necessary. Pressure pressure in the cylinder with the help of handles. Inside the cylinder, a return spring is installed, which returns the piston to its original position when the pressure is bleached through the outlet valve.

- Platform. The cylinder is installed on the platform, which is a welded structure. In the front of the platform in special holes, the pipe stops are installed. Due to the large number of holes, they can be rearranged under any configuration of the material. Also on the platform there are installation holes for installing the tool to the work surface.

- Snap. Installed at the end of the cylinder piston. The pipe bender is equipped with several types of snap-in under the diameter of the pipe and the bend angle.

Also manufactured mechanical pipe bending. The principle of their work is similar to hydraulic, however, the performance of such a tool is much lower. The pressure on the pipe is provided by a screw, which, resembling through a hole with a carvings on the tool housing, presses on the snap. Working with mechanical tube is not entirely convenient and easy, and the diameter of the pipes that it can bend, very limited. The advantage of such a tool is its price, which is much lower than the hydraulic drive models, besides, it is easier to repair and maintain.

Automatic pipe bending. Large structures that are able to bend a pipe with a diameter to 3 "are powered by hydraulic stations. The cost of such a device is high and bending pipes with such a home repair device makes no sense.

The maintenance of pipe bending is quite simple. It is necessary to monitor the condition of the cuff so that there are no leaks of oil, periodically add liquid into the tool, contain it clean. Due to the complexity of the design and high working pressure to repair hydraulic pipe bending, especially with automatic oil stations, preferably in specialized workshops.

How to bend the pipe with your own hands with a pipe bender

Make it pretty simple:

- By the diameter of the pipe that the equipment must be bent is selected.

- Then the pipe is inserted between the snap and the stops in the place where the bend is.

- With the help of the handle in the cylinder, pressure is injected, due to which its piston is put forward and presses on the pipe, giving the last form. In the process it is necessary to control the bend angle.

- After that, the pressure in the cylinder is reset, and the piston moves back.

- Then, if necessary, the pipe moves to the desired position and the process is repeated. Of particular difficulty is the bending of radial structures, such as the arches for the construction of greenhouses.

How to bring pipe manually without pipe bender

Despite the indisputable advantages of using pipe bending machines and manual pipe bending, such at hand at the right moment may simply not be. Then you have to perform this work manually.

The process of manual flexible pipes differs depending on which material was used in their manufacture.

How to Bend Steel Pipes:

- The greatest number of problems delivers bending steel pipe. Steel is a rather strong material, which in cold condition is poorly processed. Therefore, it is necessary to heat it for wondering even the semi-leaf tube. This is done with a gas burner. For small bending a pipe from a stainless steel with your own hands, you can use balloon burners, which are enough for heating of several pipes.

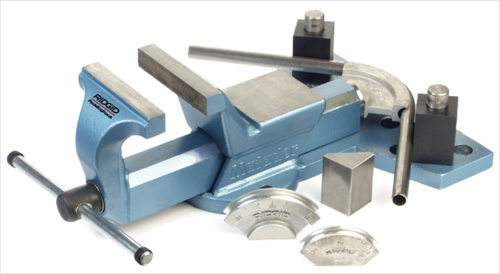

- The pipe must be clamped in vice, just carefully. If its wall is not too thick, then the sponges of the vice can leave dents on it.

- Strong the pipe is needed in revenge bend. It is possible to understand that the metal is ready for processing, it is possible by its appearance. Finished steel has a bright red look. However, the pipe is not worth it too (the folded metal has yellow-red), it may damage the pipe wall.

- Bending the pipe must be carefully and gradually, so as not to sleep it. It is not worth cooling the place of bending with water, it is necessary to give it to gradually cool. Bending the aluminum pipe with your own hands is similar.

How to flexing metalplastic pipes with your own hands. Metal-plastic pipes have recently become quite popular for mounting heating and water supply systems in apartments or private homes. For the device of the angle when installing such a material, special fittings are used. However, their value is not entirely democratic, so in most cases the pipe is easier to heat. The problem in the bending of metal-plastic pipes lies in their fragility. If you do not calculate the effort, the pipe can break and further use it will simply become impossible. So that this does not happen, a special spring is inserted into it. She is a kind of damper in order for it to not cracked. The spring is installed directly to the place of bend, and so that it does not remain inside the work, to its end tie a piece of copper wire.

Bend profile pipe With your own hands, you can with the help of rubber Cyanka. It is put on two supports (it can be either a wooden bar, or other soft material) and carefully tapping with the image, giving it the necessary form.

Making a simple pipe bending with your own hands

To bend profile pipe with your own hands in large quantities, for example, for the manufacture of a greenhouse frame, and at the same time not to buy factory pipe bending, it can be made independently. For this, a large amount of material will be required, however, there will be welded and fitter skills.

For the manufacture of simple pipe bending, you will need:

- Steel 14P channel with width of the shelf 140 mm. From it will be the founding of the bed of pipe bending.

- Steel 2p channel with a width of a 50 mm shelf. They will go for the manufacture of the frame of the main stop and the supports of the bearing approach.

- Obiama with rolling bearings with an inner diameter of 30.5 mm. 3 pairs.

- Circle steel (rod) with a diameter of 28-30 mm. From it, the shafts of the stops will be made.

- Shaft bolt and nut from the old clamp for the manufacture of the clamping mechanism.

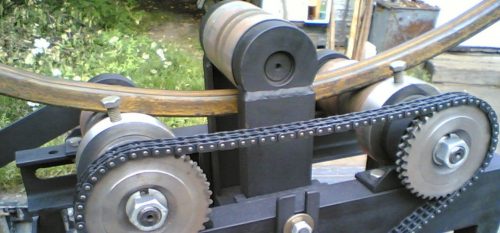

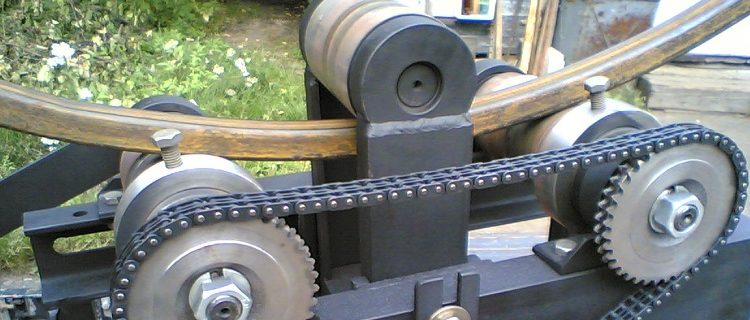

- Drive stars mechanism for filing a blank. They can be taken from the old bike.

- Circuit bike. When connecting the shafts of the chain, synchronization of their movement is achieved. Due to this tube will be supplied more evenly.

- Shaft drive. To do this, it is enough for one of the shafts to privar the pedal from the bike.

We will also need:

- bulgarian,

- welding machine,

- set of electrodes.

Order of work:

- For a start, the bed is made. Rama of the main stop is welded to the base of the base of the bed. Its height should be no longer the length of the clamping mechanism.

- After that, a hole (equal to the bolt diameter) is drilled in the frame crossbar) and the clamp nut is welded to it. Now the main part of the presser mechanism is ready.

- In the ends of the base of the base of the bed, two channels 5P are welded, the length of which will be equal to the width of the base. They are welded by shelf up. It is on them that the bearings will be installed.

- Then the pressure device is manufactured. For it, the channel 5p is cut, the length of which is equal to the width of the base, and 2 clips are welded to it. Between them the shaft is installed. The top of the presser mechanism is welded to a clamp bolt. Now when swissing it, the mechanism is lowered down, pressing the pipe to the base.

- Next, the mechanism of filing the workpiece is manufactured. The slavers welded at the ends of the base are welded with bearings, between which the shaft is installed. The same procedure is carried out on the other hand.

- At the ends of the shafts on both sides, the same asterisks are welded, between which the chain is stretched. A drive handle made from the old bicycle pedal is welded to another end of one of the shafts.

Such a design is not particularly highly high, but is quite strong, which will allow you to bend pipes for the greenhouse with your own hands in large quantities.

How to flexing metalplastic pipes with your own hands: photo