Connecting a solid fuel boiler Climate

Despite the appearance on the current market more convenient and perfect, at first glance, gas and electric boilers, solid fuel equipment always remains relevant and in demand for private construction. In some situations, for example, in the absence of access to centralized communications, solid fuel boilers are at all the only available option.

Content

Types of solid fuel boilers

To install and connect a solid fuel boiler to be performed correctly, and the equipment itself fully complied with the specified requirements, first decide on the correct type of unit. To date, the species line is wide enough, so the classification is performed on 2 signs:

Types of boilers for fuel quality

In accordance with this criterion, the following equipment modifications are distinguished:

- Wood. In such systems, it is permissible to use exclusively wood to 20% humidity.

- Pellet. Relatively new development that has gained popularity due to increased ease of use, high efficiency and availability of consumable material - granulated fuel.

- Boilers on fossil corner. The oldest option, which is also very economical when servicing.

- Combined. This category includes improved models whose functioning can be provided by any type of solid fuel.

Important! Understand how it is the connection of solid fuel boilers, a photo and video instructions from professionals will help. It is not difficult to find such benefits today.

Types of boilers on the principle of operation

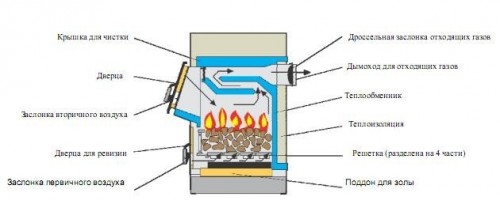

Depending on exactly how the fuel combustion system works, the following types of structures distinguish:

- Solid fuel boilers of long burning. The principle of processing of raw materials in such systems is based on a consecutive combustion process, which occurs in the direction from top to bottom. Thus, even with one bunch of portion of the fuel, the result becomes a longer and uniform heating of the coolant, due to which the desired temperature in the room with minor costs is maintained.

- Natural traction mechanism. The models of this category function at the expense of a thermostatic traction regulator. At the same time, artificial additional air supply does not occur to maintain the combustion process.

- Systems with forced taiga. A special fan is embedded in such solid fuel boilers, which carries out air into the furnace. By adjusting the intensity of the fan operation, you can independently control the speed of fuel processing, and accordingly the productivity of the unit at a particular time interval.

- Pyrolysis. Such structures are the most complex, but at the same time and effective in relation to the ratio of efficiency and performance (efficiency of some models is nearing 100%). The principle of their work is that initially the raw material is subjected to a combustion process in the primary chamber with a low oxygen medium. Processing products are a combustible gas that is the reason for ignition in the secondary chamber.

Important! Given the specific features of the maintenance of solid fuel boilers, they are made solely for the floor installation.

Solid fuel boilers - pros and cons

Before you connect the solid fuel boiler with your own hands, it will be worth familiar with the advantages and disadvantages that will bring such a solution.

Dignity

- Acceptable price of equipment itself.

- The possibility of using different raw materials as the main combustion product.

- The cheapness of the fuel itself.

- Full autonomy that does not require connecting to centralized energy seals.

- High performance indicator with single loading (80-99%).

disadvantages

- Short-range operation when blocking.

- The need for personal participation in the operation of the system is an independent loading of the furnace.

- The need to isolate the premises for storing fuel raw materials and its preparation.

Connecting a solid fuel boiler

Despite the seeming lightness, the procedure for the installation of such equipment is not easy. For this work, to ensure further uninterrupted functioning, as well as eliminate the likelihood of an emergency, bordering the risk to the life of all households, it is necessary to have a spectrum of certain skills and knowledge. Some rules and scheme for connecting a solid fuel boiler you will find below in this article. But, if you are not sure of your own, be sure to ask for help from specialists.

Stages of mounting

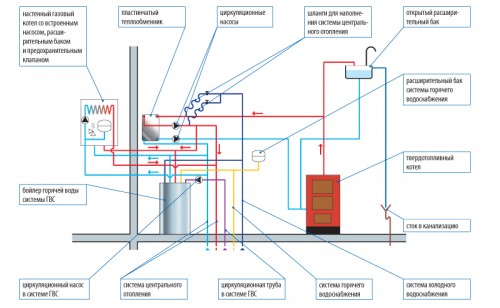

The entire process of connecting the heating solid fuel boiler with their own hands consists of several consecutive steps, ignore which is unacceptable:

- Preparation. This process includes a number of procedures aimed at preparing the boiler room and checking the already installed equipment of the heating system - the choice of premises, the preparation of the floor, the preparation of the ventilation removal and the chimney.

- Installation. The aggregates of this category differ quite large weight, so even the installation in the desired place of the boiler can become a problematic procedure for you. Therefore, enlist the support of assistants, and after placing the boiler, carefully close all the places of the adjoints and joints with the floor using the silicone sealant.

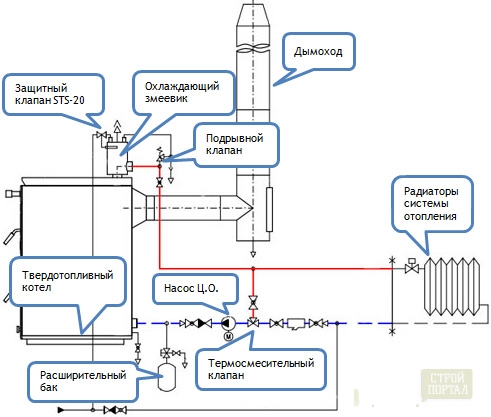

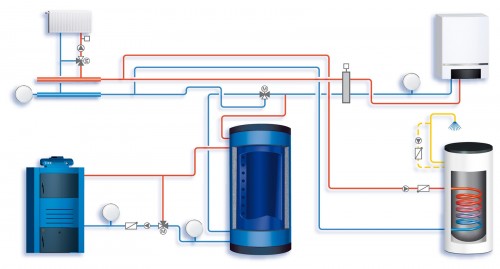

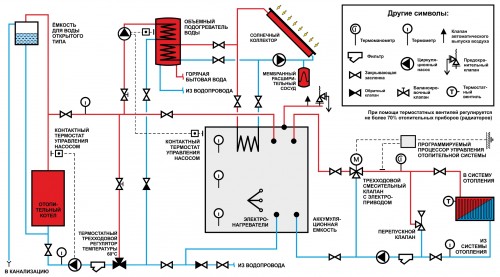

- Connecting the boiler to the heating system and DHW. At this stage, perform installation of the feed and reverse tube to the boiler, given the recommendations of the equipment manufacturer and the designation on the connection scheme.

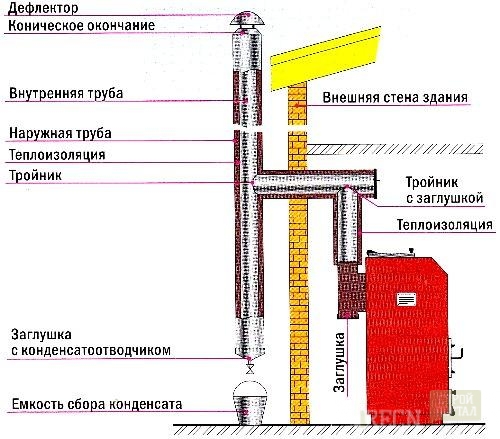

- Decoration of chimney. For the competent implementation of this work, mount the smoke pipe of the suitable cross section using the transition nozzle.

- Completion. This stage does not mean the inclusion of the system and its full loading to work without control. In order to ensure its stable functioning and immediately identify all the shortcomings of the installation procedures performed, conducting commissioning works, in other words, testing the system.

Rules for choosing premises

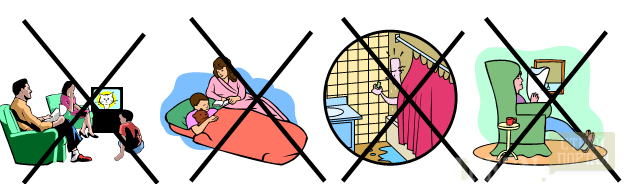

In order not to make a common mistakes that are committing a construction amateurs, be sure to consider the following requirements and recommendations that meet SNiP and Sanpine standards:

- You can not choose to install a cupboard living room - kitchen, living room, bath.

- It is impossible to mount a solid fuel boiler in a closed room.

- It is impossible to install such equipment in the immediate vicinity of explosive substances.

Recommendations for the creation of the right boiler

When arranging the boiler room itself, be sure to perform the following miscalculations:

- the total area of \u200b\u200bthe room is not less than 7 m2;

- installation location - at a distance of 0.5 m from the walls;

- the diameter of the chimney is to comply with the requirements of the manufacturer, meaning in the instructions for the boiler;

- chatting of the floor from concrete - 5-7 cm.

Important! Separately, note that the floor and walls you must arrange from non-combustible materials, and the flooring should be as smooth as possible, with no more than 2 mm / 1 m2. Before the furnace, be sure to install a metal sheet on the floor.

Ventilation rules

High-quality ventilation will provide timely removal of harmful substances - products of the combustion process of raw materials, and accordingly, your health will save, so you will certainly consider the following requirements when planning a boiler room:

- the area of \u200b\u200bthe ventilation removal cross section is from 8 cm2 for each 1 kW of the power of the boiler aggregate;

- the location of the ventilation holes: one - 40 cm from the ceiling with dimensions 40 * 40 cm, the second - 50 cm from the floor with dimensions of 30 * 30 cm;

- ventilation channels should always be opened for good air circulation indoors.

Design and Connection Rules System Elements

The system of connecting a solid fuel boiler has many nuances, the complex of which will be somewhat different depending on the specific view of the equipment you have chosen. But there are general rules applicable to the boilers of all categories that are as follows:

- Designing the heating system on a solid fuel type boiler, desigh in such a way that the temperature of the incoming and outgoing technical water is in the difference not more than 20 ° C.

- Solid fuel boiler strapping line is thinking out in such a way as to prevent the cold fluid to get into the well-hot parts of the central element. Otherwise, this can lead to cracks.

- If you choose the most acceptable type of expansion tank - open, the location of its installation is determined by the upper point of the system.

- If you use a closed heating system with a membrane (closed) expansion tank, its volume must be from 10% of the total system with the boiler.

- On the outlet pipe between the tank and the boiler, create a safety line that will be the most briefly as possible to connect these two system elements. In no case do not equip this section of the chain valves or cranes.

- The choice of a suitable installation place is determined on the reverse tube area to exclude overheating.

- On the pipe of the water supply, install the reverse siphon drainage and check valve to protect the system failure due to return pressure.

Important! The allowable rigidity of water, which is used as a coolant - 1.3 mol per 1 m3 at the level of acidity up to 8-9.5 pH. Otherwise, the likelihood of a quick output of the system under the influence of an aggressive medium is high.

Chimney Mounting and Service Rules

At the stage of the decoration of the chimney, follow these rules:

- Insert the protective liner from the stainless steel cut into the chimney from the inside.

- Determine the easily accessible places on the highway.

- Leave the holes on these sections to ensure that you continue to easily and quickly remove soot.

- At the bottom of the pipe, create a receiver for condensate.

- If the part of the chimney highway passes through the cold plot in the attic, insulate the pipe itself.

Important! All rules for servicing this part of the system are reduced to regular cleaning from the resulting soot and resinous sediments 1 time per year. Perform this procedure according to the scheme proposed in the passport to the equipment.

Rules of system testing

So that all the work did not go to the Nammark, and you were completely confident that it was done correctly before proceeding with the preventive preliminary functioning, do the following:

- Check the quality of the thrust in the chimney.

- Check the level of chimney tightness over the entire length of the highway.

- Lay the boiler only when you close the front doors.

- Do not open the doors when the fan is turned on.

Connecting a solid fuel boiler - Video

Conclusion

Competently performed installation of a solid fuel boiler is not only a guarantee of high-quality microclimate in your home, but also health. Therefore, do not ignore the above rules, check the pressure level in the heating system regularly and eliminate all current defects. So that you also do not have any questions about the compliance with the manufacturer of the CPD of a solid fuel boiler and your indicator, note that the following factors affect the effectiveness of its operation:

- the quality of raw materials;

- the quality of fuel itself;

- the quality of thermal insulation at home;

- speed, frequency and focus of wind.