Installing a boiler. Step-by-step instruction Plumbing

It is incredibly imagining a comfortable stay in the house without hot water. Her uninterrupted admission provides water heaters. Our article will talk about the nuances of the installation and connecting the boiler.

Content

Preparatory stage of the installation of the boiler

Before purchasing a water heater, it is necessary to determine the installation site of the equipment. It must comply with the following requirements:

- Free access to the boiler during the entire operational period.

- The wall must withstand the conditional double load. If the water heater accommodates 80 l, the wall must withstand the load of 160 kg.

Be sure to check the state of the wiring. It should be trigger with optimal thick. If a boiler is used with a capacity of 2 thousand W, then the copper wire must have a minimum of 2.5 mm². The cable is desirable to lay from a separate protective machine.

To the place of installation of the boiler should be pre-suspending the water pipes and make output points. Otherwise, you can encounter such a problem: the boiler will be installed, and the state of the insertion does not allow you to join it. We will have to additionally engage in the replacement of pipes.

Types of electric boilers

Water heaters are divided into two main types:

- flowing;

- cumulative.

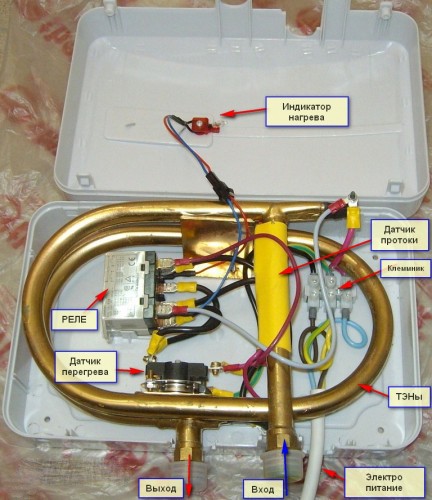

The main element of the flow boiler is a flask, inside which is a tubular electric heater (TEN). Water passes through the flask and heats up. The main advantages of the flow water heater:

- compactness;

- fast water heating.

The most economical flowing water heater will be in consumption of a small amount of hot water. This is explained by the fact that the inclusion of the TEN occurs when water moves.

Cumulative boilers are the tanks that have a different volume (from 10 l to 1 thousand liters). The flow of water in them is made from the water pipeline. The enabled heating element, which is located inside the equipment, maintains a constant temperature. The main "plus" of the cumulative water heater is to ensure hot water of several water points.

Installation of flow boiler

Due to the rapid heating of water, the flow boilers are equipped with rather powerful Tanes. For this reason, special attention is paid to the wiring. The cable cross section should exceed 4 mm². Be sure to find out the power of the automaton current to which the wiring is stacked. The strength of the current for one water heater should be within 32-40 A.

Installation of the electric boiler provides two ways to connect:

- temporary;

- stationary.

The temporary method of installing the boiler involves the use of a conventional shower hose. The algorithm for connecting the time water heater is as follows:

- a tee crashed into a cold water pipe;

- installation of a shut-off crane;

- the flexible hose crane is connected to the input of the boiler;

- the crane and water heater turns on;

- the boiler opens;

- after 30-40 seconds, hot water will be pulled out of it.

The stationary scheme of the boiler installation is in parallel water supply relative to the water supply system. The following actions are performed:

- two tees are crashed into a cold and hot water pipe;

- cranes are mounted;

- for a high-quality device of all connections, a tape of a FMU or a pacle with paste is used;

- the input of the boiler is connected to the pipe supplying cold water;

- the outlet of the hot water is connected to the locking crane;

- checking the tightness of the compounds is carried out by opening the mixer and cranes;

- if everything is in order, the water heater is connected to the electrical network.

The owners of the apartment in an apartment building need to be overlapped with hot water. Otherwise, hot water will go into the plumbing system of neighbors.

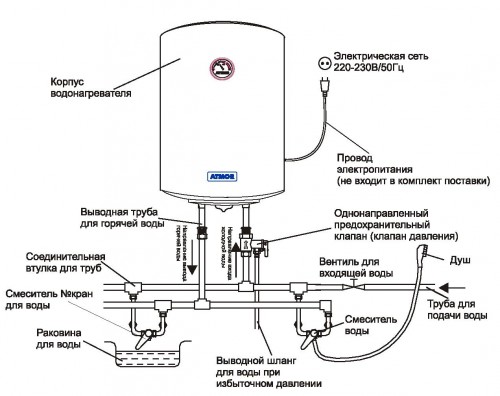

Installation of a cumulative water heater

Cumulative type boilers are more common equipment. This is explained by the fact that they are cheaper and do not need to use powerful wiring.

Installing the boiler with their own hands begins with the markup of the place of its attachment. The distance between the elements of the water heater fastening is measured. It is transferred to the wall. 2 holes are drilled (depending on the boiler model, 4 holes may be needed), the dowels are inserted into them and the hooks are twisted. The boiler hangs on the hooks.

Connecting a boiler to the water supply system is carried out depending on whether the elements of the pipe connection with the water heater are displayed or not. If the connection location is already prepared, it is possible to use flexible hoses to connect pipes with the entrance and access of equipment, which are equipped with rubber sealing gaskets.

Installation of a cumulative water heater involves the use of the valve, with which reduced overpressure in the system. It is recommended to use a tee that is placed before the shut-off valve. A crane is connected to the tee that is designed to descend the water when the boiler is maintained.

In the absence of conclusions, they need to be done. In the presence of plastic tubing pipes of the connecting elements, a maximum of 15-20 minutes is made. If the pipes are made of metal, then besides tees, you will need a dice, which should be coincided with the pipe diameter. In some cases, the adapter of the appropriate size is also required.

The sequence of actions is as follows:

- water supply is turned off;

- in the place of attachment of the tee, trimming pipes;

- with the help of the dice, thread is cut;

- the panel threads are winding;

- tees (or adapters) are connected to the pipe;

- cranes are installed.

By connecting cold water, you need to connect the outlet opening of the boiler with a crane that will adjust the supply of hot water. By connecting the water supply, the cranes are open and cold water. It is expected until all the air will be released from the hot water crane and water will not begin to flow. Immediately for the presence of leaks, all connections are inspected.

After the batter of all air boiler is connected to the electrical network. As a source, it can act as a socket and a separate automatic. The sensor that burns on the boiler will indicate the normal supply voltage. Temperature adjustment is carried out according to the instruction manual.

Installation of gas equipment

Naturally, it is prohibited to make the installation of a gas boiler with a "zero". It would be for the gas workers service. Independently carry out replacement of the gas cylinder can, when installed service representatives gas meter.

When installing a gas cylinder produced the following works:

- are marked places for holes for dowels;

- drilled holes and the hooks are mounted;

- hung gas boiler;

- fastening occurs corrugations which removes carbon monoxide in the flue;

- a gas pipe connected to the port through which gas enters the boiler;

- compounds is checked;

- is supplied to the boiler water and verified by normal system operation.

When installing bellows one end should fit dock with chimney. The other end of the bellows is worn on the outlet of the water heater. Before purchasing corrugations carefully made all measurements. Its inner diameter should match the outside dimensions of the boiler opening.

For connecting the gas pipe to the inlet hose using a special rubber. After a secure fit all hose joints are covered with a soap solution. Opens the gas valve.

As long as the gas is directed to the boiler, you need to carefully inspect the joints. If at a certain site were soap bubbles, this indicates a gas leak. With the key are pressed nuts on the "problematic" areas. If the leak could not be eliminated, it is best to contact the experts of the gas service.

After connecting the gas to the boiler is necessary to bring him water. It also uses a flexible hose. The water supply to the gas water heater is carried out in the same manner as the electric heater is connected.

Schematically sequence elements shown as follows: "pipe adapter crane-pipe-hose-heater". The inlet of cold water is indicated in blue, the output from the hot - red. To increase the operational period of the boiler on the pipe which supplies cold water, saline installed filter.

Unfold taps with hot and cold water. Check all connections. If there is a leak, they should be eliminated by tightening the screws or use new tow. Gas is supplied and opens hot water valve. After 20-30 seconds of mixing hot water has to go.

Features horizontal boilers

The most optimal solution for premises that have limited vertical space are horizontal installation boilers. This equipment is characterized by simplicity of installation and rapid water heating. They are ideal for rooms in which there is a niche.

Horizontal household water heaters have a tank of 30 to 100 liters. The inner part of the equipment is made of stabilized steel, which is covered with a biostocloofarfor. Most boiler models have an environmentally friendly polyurethane foam layer, thanks to which thermal losses are prevented. The power of the Tan horizontal boiler is 0.8-2 kW. The magnesium anode located near the Tan will increase the service life of the equipment.

Mounting and connecting the horizontal water heater is largely similar to the installation of an electric boiler. The presence of a steel flange that is attached to the body bolts makes the installation even easier. On the flange there is a fastening of heating elements with anode. A thermostat that has double protection is used. It is designed to adjust the temperature.

A distinctive feature of the horizontal boiler is the process of mixing cold and hot water in the tank. This is due to the fact that the upper (with warm water) and the lower (with cold water) nozzles are too close to each other. This design feature is the cause of rapid cooling of water, which is supplied from a hot crane. Therefore, it is better to acquire a water heater, which has a heat exchanger.