Grinding machine on wood. How to choose and use Instruments

Grinding machines on a tree occupy a leading position among the most popular woodworking devices. They save the mass of time, strength, allow you to work with an accuracy of millimeters and always give an impeccable result. In this article, we will tell you how to choose a grinding machine on a tree and how to use it as efficiently as possible.

Content

Specifications

The wood grinder is an indispensable tool for repair and finishing works in a country house. If you like to work with your hands, build a house or started overhaul at the cottage, such a tool will make the work quick and pleasant. Grinder significantly accelerates the processing process, so grinding and polishing cease to be a tedious occupation. Convenience and compactness of models allow you to perform any work and align the wooden surfaces of any type.

Types of grinders

There are several types of household grinders. Their appointment is determined by the characteristics of the structure and the principle of work.

If you need a tool for repair and construction, carpentry and carpentry, you can use such types of machines:

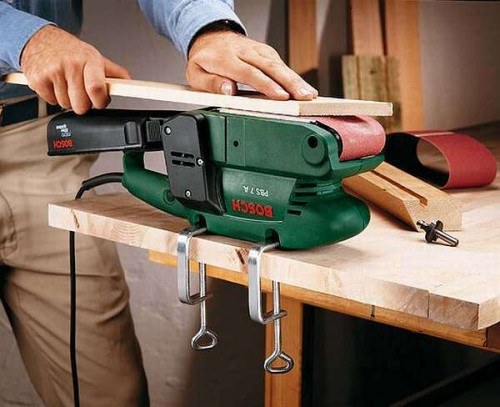

- Ribbon - designed for aggressive treatment of various surfaces, including plastic and metal. Due to its versatility, the most popular in amateur and professional circles. In this article, we will look at the features of the ribbon grinding machine on a tree in more detail.

- Vibration - with the help of vibrationlifmashin, more delicate treatment of wood is carried out. Soft circular movements with a small amplitude gently affect the wooden surface. The grinding surface is rectangular form, which is very convenient when treating corners.

- Deltashlifmashina - is a type of vibration machine, but is characterized by a triangular shape of the grinding surface. It is used to process hard-to-reach places, recesses, corners.

- Eccentric - grinding for high-quality surface grinding to polishing condition. This is achieved through the simultaneous impact of the oscillatory and rotational motions of the plate. Suitable for processing large smooth surfaces (small areas and internal corners will have to be polished manually).

- Brush - grinding machine, the working part of which is not an abrasive ribbon, but a metal brush. Used to remove old coatings (varnish, paint), rust removal or limestone plaque. The brush gripper on a tree is designed for large areas. Such a brush is convenient to clean boats, parquet, update old countertops and work with other large-sized objects.

Ribbon grinders

Ribbon grinding machines on wood are used to quickly remove rather thick layers of material, for example, for grinding boards or removing the old paint layer. They are also used to process lines of cuts and an accurate fit of various wooden parts.

The principle of operation of the ribbon grinder is quite simple - the abrasive ribbon closed in the ring is spinning on rotating rollers and removes the layer of the material being processed. The result can be compared with the work of the ruble. The thickness of the layer that you want to remove directly depends on the size of the grain on the abrasive ribbon.

Advantages

The main advantage of the handmade grinding machine on the ribbon type tree lies in its multifunctionality.

Grinding machine can be used for the following purposes:

- accurate trimming in accordance with the layout line;

- processing of very coarse surfaces;

- grinding and alignment;

- giving the right form;

- smooth rounding of elements.

Despite the high capacity of the operation, ribbon machines are characterized by a linear effect, which provides a delicate finish, even if a ribbon with large grain is installed. This features a ribbon type from vibratory or centrifugal.

If you need to quickly rush a tree, you will not think of anything better than ribbon grinders. It is ideal for smoothing irregularities and polishing.

Useful advice: Aggressive processing is better to start grinding at an angle towards the fibers, and to make the surface smooth - along the fibers. Start the operation of tape No. 80, and polished - No. 120.

How to choose

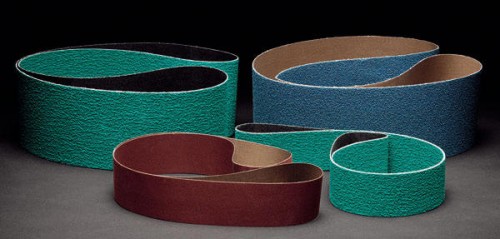

To choose a truly good grinder, first you need to familiarize yourself with the information about abrasive tapes. Models are classified in size. So, the smallest grinders can work with 6.3 cm width ribbons. These are light tools with which you can easily cope with one hand. Heavyweights work with 10 cm wide ribbons and are used to handle large items. The optimal option for a manual grinding machine on a tree - tape 7.6 cm.

The choice of tool must first depend on the target. So, if you need a repair machine or hobby, you can easily do with simple inexpensive miniature models. If you want to buy a grinding machine on a tree for construction or business (furniture workshop, for example), it is better to give preference to more large-sized models.

Also when buying a tool should be set to a set of different-caliber tapes.

Grinding tapes are two species depending on the abrasive material:

- Zirconium - coarse aggressive grinding, can form scratches that will have to remove fine-grained ribbons. Suitable for processing metal surfaces (sharpening axes, knives, etc.).

- Aluminum oxide - provides a more sparing effect on the material being processed. Suitable for grinding any wood breeds.

In addition to the dimensions of the machine and the tapes used, you should pay attention to the additional features of the device. So, in the work it is useful for smooth control of the speed of rotation of the tape, as well as the function of automatic centering of the abrasive tape (will not let it crawl from the rollers). The price of a grinding machine on a tree depends on what tapes it is intended.

Setting the grinders

If you have already chosen and bought grinders, it's time to start setting up the tool. Even the most expensive professional grinding machine on a tree need setting. This skill must have every Master Stolar, if he wants to achieve perfect results.

The grinding setting is as follows:

- Make sure the tape is installed correctly. Some types of ribbons are better to set in a certain way - usually the preferred direction of the installation is indicated by arrows on the back of the tape. If there are no such arrows, the abrasive tape can be installed as you like.

- Check if the adjustment of the location is needed - the tape must be installed clearly centered. To do this, you need to raise the tool, turn on and trace, will go to the tape or not. Fix the machine in the working mode using the guide roller and install the operating surface in the center.

- When working, additional correction will be required if, of course, the automatic tape centering feature is not provided on your grinder, which was mentioned above.

Helpful advice: All models of grinding machines on a tree are sold complete with a special reservoir for dust collection. However, in fact, its effectiveness is far from perfect - some of the dust is scattered on the workshop. To eliminate this shortcoming and not waste time cleaning, connect the grinder with a vacuum cleaner using a conventional elastic tube. So the dust will not interfere with work, and you do not have to make cleaning every time.

Safety regulations

Ribbon grinding machines on wood are considered fairly safe tools, because they are not equipped with cuttings. But despite this, working with them requires mandatory observance of safety.

How to protect yourself from injuries when working with grinders:

- Always wear sound-absorbing headphones, so as not to injury the eardrum - grinders are very noisy during operation.

- Take protective measures from dust - wear a respirator or just a wet handkerchief on your mouth and nose. Inhaling wood dust is very harmful and quite unpleasant.

- Protect your eyes from chips and dust. To do this, buy special building glasses.

- If you need to change or clean the dust collector, be sure to de-energize the grinder.

- If you use grinders for processing metal surfaces, additional protection against sparks will be required. Also make sure that you have easily flammable materials and combustible mixtures near your workplace.

- Before connecting grinding to the network, make sure that the power button on the tool itself is in the "Disabled" position.

Helpful advice: If you need to perform a large amount of work at a time, facilitates the task of a special rack, on which you can fix the grinding machine in a convenient position. This will allow you to easily wrap myself, and not a heavy tool. Of course, we are talking about professional oversized sizes. But in the case of continuous processing of small parts, it is advisable to manipulate them, and not a typewriter, substituting the surface under the tape at the desired angle.

Finally, we suggest you familiarize yourself with the review of various types of grinders on a tree: