Installation of the recovery Climate

The air recuperator is a subtle-exhaust device, with which the exhaust air is output from the room and fresh from the outside. The device is arranged in such a way that it takes the heat from the outdoor air and gives it to the street from the street.

Content

Principle of operation of the recovery

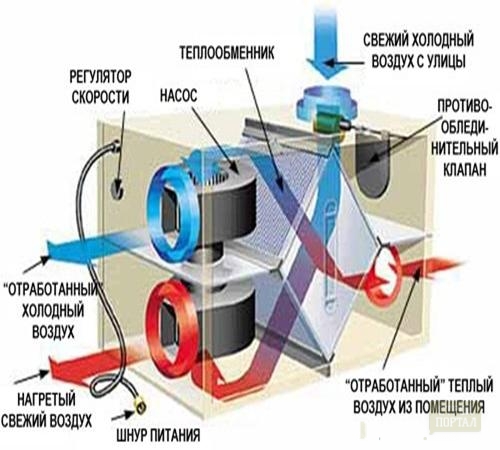

A very important point is that the air-introduced and the air injected is practically not mixed. This is ensured by equipping the design by a special separator, which can be made of plastic, copper, aluminum or galvanized. The air is a trimmed, the recuperator promotes parallel with exhaust, and its heating occurs when the stream energy is transmitted.

Also, the design of the recovery provides for the presence of lattices on the hole, through which the air falls from the street into the room. It delays dust, dirt, floral pollen, small insects, which storing to penetrate someone else's territory.

When the device displays the air out of the room, along with it it takes room dust and bacteria. Thus, we see that due to the recuperator, the suppress and exhaust air in the house is updated, cleared, heated.

Almost all models of these devices can work in a quiet mode, without interfering with rest and sleep or children nor adults. Modern recovers released in recent years have a small size, simply mounted, have a wide range of additional functions, in addition it is attached to them, which makes it possible to turn on and off the device at a distance.

Varieties of recuperators

Existing models of recuperators have different characteristics. Depending on them, devices are divided into the following types:

- recuperator plate;

- rotary recuperator;

- camera recuperator;

- recuperator equipped with an additional built-in heat exchanger;

- combined thermal tubes.

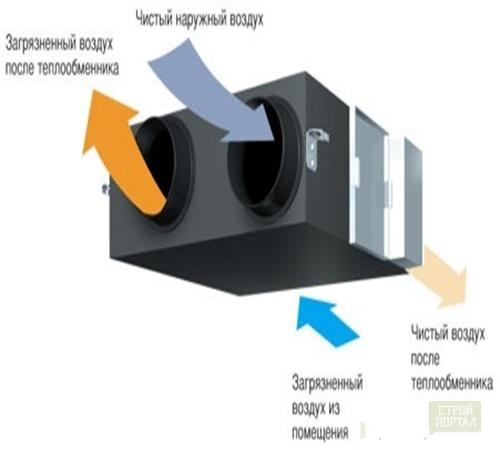

1. In the first case, the heat exchanger is one or more stationary installed plates: copper, aluminum, plastic, etc. Air passes through them, and due to the temperature difference of the oncoming flows, condensate is formed, which in the cold season can turn into ice. Most often in the design of the device included elements that remove moisture and preventing icing due to reinforced heat supply.

As for recuperators with a heat exchanger from one plate, then when the moisture begins to accumulate in them, the device directs the air flow bypass, while displaying condensate through a specially spaced opening.

In case of icing, the valve inside the recuperator closes the flow of air masses, and the heat emanating from the plates, heats the structural elements.

The peculiarity of the plate devices is that air flows in them cannot be mixed, and the filtration system produces high-quality air purification from various kinds of contaminants.

Use in the design of ribbed plates gives her the opportunity to work more productively, increasing reliability and increasing service life.

The scope of lamellar recoveors is quite wide. They can be seen in residential and office premises, hospitals, categories and other places.

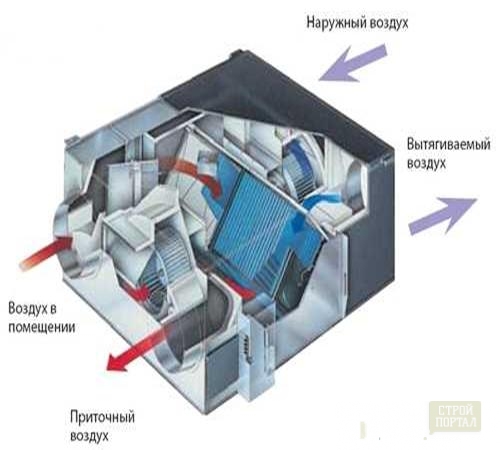

2. The rotary recuperator has its own characteristics. They are in the presence of one or pair of rotors with rotating blades, thanks to which air flows are moving. This recuperator usually has a cylinder form. Its design includes a rotating drum, thanks to which the air movement occurs. Moreover, the movement takes place first, then in the other direction, and air flows move accordingly.

The rotary heat recuperator is much more productive with a plate, but it is very cumbersome and most suitable for industrial premises. In medical institutions and the organizations of catering, it is also not installed, since The device allows mixing of opposite air flows by 5-7%.

3. Chamber recuperators work differently. Exhaust air masses are sent to a special compartment, the walls of which they give their heat and are outward. The air from the street, although it passes into another separation of the device, takes heat from the borders and enters the room.

4. Recoverators with an additional heat exchanger are not as good as previous species. They have a very small productivity, and the reinforced heat transfer provokes the appearance of a large amount of condensate.

5. A device consisting of several tubes works as follows: an additional heated room air occurs, it turns into pairs, after reverse condensation occurs. Such devices are good in that the air from bacteria is completely protected.

The criteria for which the recovery model selection should be as follows:

- room size;

- degree of humidity in the room;

- purpose of the room;

- the need to comply with silence indoors;

- device performance;

- the cost of the device along with installation.

If someone wants to purchase, but cannot decide on the type of recovery, the reviews left on the Internet may be very useful.

The main functions of the recuperator

Consider more this topic on the example of the MARLEY device. The recuperator of this manufacturer is very effective and has a high efficiency. Its main functions:

- significant reduction in electricity costs;

- air renewal, as well as its cleaning from humidity, pollution, various odors;

- air temperature control indoor;

- derivation of used air masses;

- there is no need to ventilat, in connection with the indoors there are no drafts, dust, insects, does not prevent street noise;

- a high-quality device, for example, the German company Marley, will serve as faithfully for many years.

But the main, the very first function of the recovery is ventilation.

Production and installation of the recovery with their own hands

There are cases when a cheap and practical recuperator is needed, for example, in the garage, because for such purposes it is a pity to spend too much, but at the same time the ventilation is still needed.

If you buy a ready-made recuperator, it can be rather tangible, especially if a person does not have a big budget. In order to save it, it is quite possible to build a simple lamellar device, with an average efficiency, but at the same time very inexpensive.

Formula for calculating the power of the self-made device: 0.36xqxdt. In it, DT is a temperature measured in degrees; Q is the number of cube. meters per second.

In order to independently make the recuperator, the following materials will be required:

- roofing galvanized - 4 sq.m;

- technical cork - strips in 2-3 mm thick;

- plastic flanges, whose cross section is equal to the section of the air pipeline;

- neutral sealant;

- silicone;

- insulation;

- MDF or wood timber.

Sequencing:

- Take MDF and make a box from it by posting it from the insulation insulation. It is quite suitable for fiberglass or minvat with a thickness of 5 cm. After you need to make holes for the flanges and insert them. When the box is fully assembled, we will treat all the slots with silicone.

- Now divide the material on the fragments of 20x30 cm and fold into the stack of 3 units. Remember that the segments should be perfectly even and the same.

- Implement the design, use a sealant for this. For the efficient operation of the heat exchanger, its plates must have an area of \u200b\u200bat least 3 sq. M, while the gap between them should be left for less than 4 mm. The material for the frames between the plates is the technical cork. Her strips secure polyurethane glue.

After the actions described, the device can be operated in principle, but for ideal work it is better to still install the sensor that locks the pressure drops and the box from the waterproof GLC. Thanks to the sensor, the recovery will occur during the winter period. The box should be mounted where the air duct is found. It is necessary to build it from two layers of the material of GLC, and inside inspire. Upon taking this measure, the system will be less noise, and more economically work.

If for someone the above-described process is quite complicated, then it is better not to bother myself, but just buy a recuperator. Make it is pretty easy, just open the Internet and go to sites of specialized shops and firms.