Roof Waterproofing: Materials, Mounting Features Insulation

The first priority of any roof is the protection of the building from the cold, wind, sun and precipitation. The better and better the roof of the house will be performed, the greater the likelihood that in its rooms will always be dry, warm and cozy. To indoors, water and moisture did not fall, it is very important to take care of the roof waterproofing. We will tell about suitable for this material, as well as on the features of their installation in our article.

Content

Water-repellent materials: Requirements and specifications

It is possible to perform high-quality waterproofing of the roof in the event that the materials used will meet the following requirements:

- They must be waterproof - this is perhaps the most important of their characteristics.

- It is desirable that the waterproofing tools have been sufficiently elastic, since the rigid elements are very inconvenient to use the roofs of a complex figure design.

- If water-repellent materials are also in the heat-insulating properties - this will significantly save on a roof insulation.

- Strength is another important characteristic of the waterproofing layer. The means used for waterproofing should well withstand physical exertion and be resistant to mechanical damage. Fragile materials for a similar purpose are simply unsuitable, because even through the slightest damage to the moisture coating will penetrate inside the design, destroying it.

- For some types of roofs, it is worth picking materials with good vapor permeability. This parameter is very important if there is a residential premises under the roof of the house, for example, attic.

Some people want to save, strive to separate the roof only with high-quality roofing material, thinking that its strength will be enough to protect the construction from all adverse natural factors. Meanwhile, roofing material is able to protect the building from the effects of wind, cold or hot sun, water freely penetrates the gaps and the slots of such a coating, destroying the roof design from the inside. That is why roof waterproofing is very important, and to choose the appropriate material, it is necessary to take into account its technical characteristics:

- An important indicator of the quality of the waterproofing layer is its vapor permeability, especially if we are talking about a warmed roof. The vapor permeability of the material allows moisture from the heater of the insulation into the underpants space, subsequently weathered from there with a natural way. In the event that this indicator is relatively low, the moisture will gradually condense in the insulation, which will deteriorate and will lose its useful qualities. The superdiffusion membrane is considered material with increased vapor permeability, which can be mounted directly on the insulation layer, without creating any intermediate frame. As for the lavetled roofs, it is permissible to hydroize the means having low vapor permeability.

- The technical characteristics of such materials also include their waterproof, which consists in the ability to withstand direct contact with water for a certain time. When finishing a flat roof it is very important that the water-repellent ability of the material was high, because water is delayed on the roof during precipitation. For the pitched roof, the waterproof indicator is also important, because sometimes the roofing material itself can have a depression or provisions. It is desirable that the waterproofing layer has withstood the pressure of at least 1.5 m of aqueous pillar, and the membrane with an indicator of 4 m of aqueous pillar can even be used as a temporary roof.

- An important technical characteristic of the waterproofing material is the mechanical strength, since in the process of laying roofing material, its individual elements may damage the integrity of the film. Where it has been broken, subsequently the places of leaks may subsequently. The tensile strength is measured in 1 m² weight units. The film is considered to be a reliable material that can withstand 100 g / 1 m².

- If the waterproofing film acts as a temporary roof, it should also be resistant to solar studies.

Types of water-repellent materials for roofing

Polymer membranes

The membrane of polymeric materials is considered a popular means for waterproofing the roof. Such a film is rather durable and is capable of listening for at least 25 years. In addition, waterproofing membranes are durable, environmentally friendly and not combustible.

There are several varieties of such material:

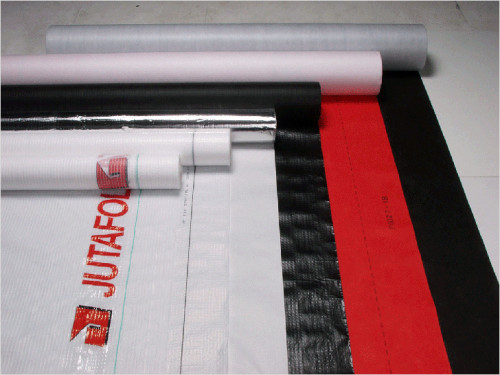

- Perforated membranes are materials having microquosity. Such waterproofing is used on roofing any configuration, but it is impossible to lay it directly on the insulation layer. Between the heat insulating material and the hydrophobic membrane, it is necessary to leave a small space for air penetration.

- Superdiffusion membranes, in contrast to the previous species, can be mounted on the insulation itself. Such a film is made of nonwoven material and is most often used in the decoration of the attic roofs.

- Anti-condensate membranes are made of nonwoven material that can absorb moisture particles. This film, on which condensate, is not formed, is most often used in the finishing of metal tile roofs.

- Polyvinyl chloride membranes are dense waterproof films consisting of 3 layers: 2 external layers are made of polyvinyl chloride, and in the middle there is a layer of reinforced polyester.

- EPDM membranes are a material produced from a thermoplastic rubber. Such waterproofing is conveniently used on the roofs of any configuration, even on the most complex in the form of structures. The service life of such membranes is 25-50 years. Separate sheets join themselves without adhesion, and the connection places are sampled by a special tape. EPDM membranes have high strength and elasticity, well tolerate frosts, heat, sharp change change and direct exposure to sunlight. Such films are very well stretched, increasing by about 2-3 times, so that they can be placed on the roof of any form. You can only damage the EPDM membrane only with an acute subject or chemical solvent. For better protection of waterproofing, it is desirable to operate with acrylic composition.

Roll materials are mounted on the roof in several ways:

- The mechanical method of attachment involves the use of screws, bracket or nails. Such a method is used to finish light roofs, which cannot be created excess weight loads.

- Another method of fastening membranes is ballast. It can only be used on those roofs where the angle of the skate does not exceed 10 °. With a ballast method, the waterproofing film is first attached to the perimeter of the roof, and then sprinkled with a layer of rubble or gravel.

- In case the roof has a complex structure, the hydrophobic material is most convenient to lay everything by gluing it to the surface.

Fooling materials for waterproofing roofing

Refractory waterproofing materials have a sufficiently liquid consistency and are applied to the surface by sprinkling. One of the most popular means of this type is the bituminous mastic for roof waterproofing. Such mastic has a long service life, which is about 20 years. However, the material is not enough high quality with time loses plasticity and becomes vulnerable to physical influences.

Bituminous waterproofing of the roof is carried out by applying material to the surface of the roof of the layer, the thickness of which is at least 5 mm. It is possible to use a similar tool on flat and on pitched roofs with a slight inclination. Depending on the component composition, the hydrophobic masts are bitumen rubber, bitumen-polymeric and simply polymer. And depending on how to use, there are 2 types of mastic: hot and cold. Hot are distinguished by the fact that before applying to the surface, they should be heated to a temperature of 160 ° C. Cold mastic can be used in two ways: if the air temperature is more than 5 ° C, the mass is applied to the roof in a cold form, but if the work is carried out at lower temperatures, the mastic must be heated to 70 ° C.

Mastic for waterproofing roof has many advantages:

- It has high adhesion and is perfectly engaged with the surface of any structure. Such material can be applied on roofs made of stone, wood, concrete, metal or bricks.

- The coating material allows you to create a solid seamless coating on the treated surface. It will not be cracks, cracks and gaps, through which moisture can penetrate the room.

- Working with waterproofing mastic is easy, it is suitable for processing the roofs of any configuration and does not require the creation of an additional framework.

Painting roofing waterproofing

Among the materials for waterproofing the roof there are painting agents represented by various emulsions, varnishes on the bituminous and polymer bases, as well as special colors. Very often, such fluids are not used as the only defense, they are rather designed to extend the life of the roofing material and are applied directly to its surface.

Paints are suitable for roofs of any type and shape. In the process of operation, the mass is applied to a surface with a wide brush or sprayer. The layer thickness ranges from 3 to 5 mm. The service life of such funds is short and amounts to no more than 5 years. After this time, the layer of such waterproofing should be applied again.

Hydrophobic hydrophobic materials

Affordable and relatively inexpensive way of protection against moisture is considered waterproofing the roof of a film on an adhesive basis. Such films are available in the form of rolls made of rubberoid, fiberglass, pergine or polyester. A plus of such a material is the simplicity of its application, besides, the price of inlet waterproofing for the roof is not as high as some counterparts. Despite the available cost, similar funds have good strength, high quality and long service life.

Some of the materials can be used not only as waterproofing, but also as the main roofing coating. Such materials include rubberoids that cover the roofs of a flat type.

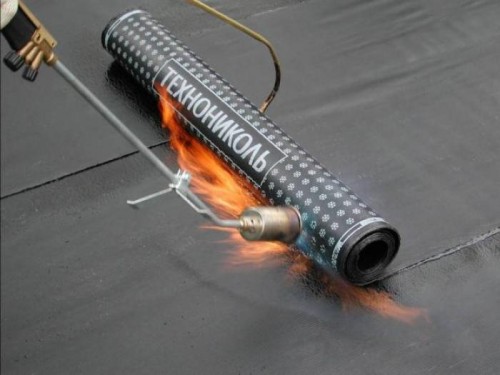

Half agents are fixed on the working surface in two ways. The first of them is carried out by heating the material, and the second implies the sticking of the film under pressure. Sometimes the sheets are additionally attached to the roof with screws or nails.

Flexible bituminous tile

Sometimes the waterproofing material can simultaneously play the role of the finish decorative roof decoration. This means include flexible tile, which performs the functions of roofing material. Among its advantages can be called such:

- Speed \u200b\u200bin work. The bituminous tile is fixed on the crate made of plywood or chipboard.

- The material looks attractive, has a wide variety of shades.

- Such a coating does not require additional care, and also has good strength, because the upper layer of the tiles consists of stone crumbs.

- A similar means saves money without conducting additional waterproofing of the roof.

- Tile is durable and during operation does not lose its decorativeness.

Waterproofing roof sheet materials

Sometimes roof waterproofing is carried out by laying sheet materials made of metal or plastic. Metal sheets can be made of lead, aluminum, copper or stainless steel. Plastic waterproofing is made of vinylplast or plastic.

Depending on which the configuration is roofing, the material is fixed on the working surface with screws or welding. Most often, similar waterproofing is used in public or industrial buildings, since not all owners of private houses can afford its cost.

Roof Waterproofing Plastering Mix

In some cases, the protection of the roof from water and moisture is provided by applying a special plastering composition. This means consists of cement and various polymer fillers. Such plaster does not let moisture, prevents the formation of condensate and is an environmentally friendly and safe material.

However, there is a substantial minus in such a waterproofing. A few years later, the material loses the plasticity, becomes more fragile, cracks and places sat down. Fix the similar problem is the easiest way to fully replace the plaster layer or using another hydrophobic material.

Waterproofing penetrating type

If the roof of the building is made of porous material, penetrating compositions can be used for its waterproofing. Such materials are used to cover surfaces from concrete, limestone, brick, foam blocks, etc. Before applying the hydrophobic layer, the working base should be prepared, carefully cleaned it from dirt and degreasing.

A huge advantage of such compositions is considered to be their ability to penetrate even the smallest cracks and pores, filling and strengthening the processed material from the inside. For such waterproofing, liquid rubber, liquid glass or special synthetic resins are used. It is easy to work with such compositions, they are applied to the surface using a pulverizer.

Features of the choice of waterproofing material for the roof

Determining with what kind of waterproofing is to purchase, it is worth considering the following:

- the shape and configuration of the roof;

- the purpose of the roof;

- view of the insulation, which is used for thermal insulation of the structure;

- the type of roofing material to which the roof is finished.

Choosing a hydrophobic coating, listen to some recommendations:

- If the roof from the inside is insulated with foam, you can do without a waterproofing layer in general. It is enough just to close the joints between the sheets of the insulation, so that water and dampness did not fall under them under the roof.

- On the roofs of flat and inversion types, it is more convenient to lay membrane waterproofing, combining it with insulation. For such structures, various mastic, painting and coating materials, as well as waterproofing penetrating action are also suitable. Such materials can be used both for processing the entire roof area and for embedding seams, cracks and gaps.

- As a roll material, it is cheaper to use runneroid or more modern its counterparts: EuroRuberoid and a ruble.

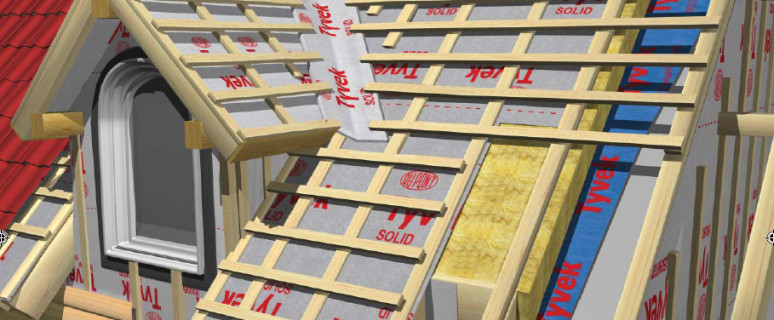

- Residential attics and attics are best waterproof using superdiffusion membranes. They are used with the layer of insulation and vaporizolation. In general, membrane materials are better than everyone else suitable for finishing the roofing of complex shape.

- Some time ago, the roofs decorated with slate were waterproof using a rubberoid, but recently a more popular tool for such structures is considered a hydrobarrier or perforated film. The same film is placed under the metal tile, fixing it on the rafted nails or brackets. For the installation of the film, a doomlet of wooden plates is used. By the way, for disgraced attics, a perforated film in combination with the insulation is considered the cheapest and practical option.

- Fold roofs, as well as structures decorated with metal roofing materials, are best waterproof using an anti-condensate membrane. When installing such a membrane, two ventilation gaps should be provided, and this should additionally do the crate.

Waterproofing roofing with their own hands

Flat roof finish

Waterproofing of the roof of a flat design is most often performed on a concrete base. The material for such work should be selected with special care, because it is on the roofs of such configuration that leaks occur most often. The thing is that the flat design does not allow to make slopes for the water lead, and even the sludge puddle on the surface will definitely find a path through a poorly performed waterproofing layer.

Flat roof waterproofing agents are somewhat, most often used materials:

- rolled bitumen membranes;

- liquid rubber and bitumen mastics;

- painting formulations;

- liquid glass;

- polymer membranes.

Work on waterproofing of a flat roof can be described in stages:

- Before starting the roof waterproofing process, the working base must be prepared. All the gaps and joints between concrete slabs should be thoroughly smeared with a mortar, which is also desirable to add some liquid glass. At 1 kg of cement mortar should account for about 30 g of substance.

- The intermitted joints must be left for a while that the cement mixture is completely dried.

- After that, you can lay the first layer of waterproofing - rubberoid. Ruberoid is a dense cardboard impregnated with bitumen and covered on one side with shallow quartz chunks. Installation of waterproofing of the roof is made of pearls, separate sheets are overlapped with joints by about 10 cm.

- A layer of a sandy-cement solution is styled on top of the runneroid, the thickness of such a layer should be about 2-3 cm. If you have a screed for all the rules, it will be homogeneous, without cracks and can protect the roof from moisture and dampness. So that the solution did not crack in the drying process, it is covered with a reinforcing grid 5x5 or 10x10 cm. Crude surface is covered with a polyethylene film and moisturized every 3 days for 2-3 weeks.

- After complete drying, the screed should be thoroughly projected. The means for primer can be purchased ready, but you can make it with your own hands, mixing the building bitumen with gasoline.

- On top of the dried primer, it is possible to lay the last layer of waterproofing, for this purpose it is convenient to use rolled colore materials. They are fixed on the surface by heating with a gas burner or a soldering lamp. Initially heated the screed in the place where the material will be laid. Then heated one side of the roll, put it on the processed area and put it tightly, trying to simultaneously drive out air bubbles from under the waterproofing layer.

- In the same way, the remaining bands are laid, making a total of 10 cm.

- In those places where walls, parapets or other barriers are towers over the roof, the waterproofing roll should be started on a vertical surface of about 20 cm in height, then glue it at this level. And so that the moisture did not hit the material sheet, its end is protected by galvanized with a tide. The gap between the tint and the wall is poured by bitumen or water-repellent sealant.

You can additionally protect the roof from moisture using a paint material that is applied on top of the main waterproofing with roller, brush, spatula or sprayer. The layer of the painting material should not exceed 5 mm.

Roll facilities for waterproofing roofing are quite reliable, but through poorly, the cocned joints can leak water, which reduces all efforts from the work performed. Alternative rolled materials can be liquid masts. They allow you to create a smooth seamless layer on the surface, which is guaranteed to protect the building from dampness. Consider the subtleties of the application of bitumen mastic on the roof:

- To work with such material, use a compressor, roller or brush. The layer of such waterproofing should be approximately 3-4 mm.

- Before processing the roof, its surface must be cleaned and degreased, then cover the primer and let dry. The primer is better to choose the one that is recommended by the manufacturer of the mastic used.

- The bitumen mastic drying period is approximately 5-6 hours. In many cases, the material is applied in several layers, giving each new layer to dry for 3-4 hours. As a rule, the exact time is indicated in the instructions for the product. If you do not comply with the technology, the material may be stamped and lose its water-repellent properties.

- In the case when a cold composition is used for waterproofing, its density can be changed by making a certain amount of solvent. Such solvent can be low-fledged gasoline. Often, cold mastic is bred by gasoline when they want to reduce its viscosity and facilitate the process of applying material in cold weather. It is important to know that the divorced mastic dries out several times longer.

- Sometimes the waterproofing of a flat roof is carried out with liquid glass. To do this, use a pulverizer or compressor. Such a coating penetrates all concrete pores well, but it is short-lived and will require a replacement after 5 years.

Waterproofing of the roof of a bunk type

Rolled materials are best used as water-repellent means for a bone roof. If the bias of the roof is quite large, coating and painting agents for such a work will not rise, as they will flock down, do not have time to dry.

Consider in more detail the technology of waterproofing of the bartal roof on the example of using the runneroid:

- The roll of the material starts to roll and fixate, heading from the bottom-up. The edge of the rubber belt is attached to the edge of the roof, then the roll is rolled until the skate reaches. In this place the material is also fixed reliably.

- Separate sheets of rubberoid are superimposed by each other, which is approximately 15-20 cm.

- Waterproofing the roof of such a configuration is carried out perpendicular to the rafters, to which the material is attached using a construction stapler. Along the rafted sheets are fixed by the counterbours.

- To create a gap for penetration of air between the roofing material and the waterproofing layer, perpendicular to the rafters is set by a counterclaim.

- On the trimmed roof can be laid slate.

- On the inner surface of the roof, a vapor insulation layer performed from polyethylene or pergamine is mounted.