How to set foundation Useful advice,Construction

The basis of any building is the foundation. Those, the well-being and life of the whole house directly depends on its integrity. Therefore, this part of the building is usually initially made of durable and wear-resistant. But even such a solid component of the construction of the house over time begins to collapse under the action of atmospheric moisture and precipitation, if not bothering about its protection at the construction stage.

Content

The sampling for the foundation is the one insignificant, it would seem that the element that protecting the foundation from snow and the rain ensures the preservation of the structure, increases its resistance to various kinds of deformations.

Functions and types of sings for foundation

Why do you need a cast?

- From aesthetic considerations. The tump is a trifle, without which the building looks unfinished, the scene is inaccier.

- With trickening purposes. This element protects the foundation from the negative impact of atmospheric phenomena, preventing its deformation and destruction.

Molding form

The design is a kind of "visor" of the base, adjacent by one cut to the wall. The other of its curved slice covers the foundation.

What are the flows?

The construction market presents a wide range of sings for the foundation, the price and qualitative characteristics of which vary. What is the difference?

- Metal with polymer coating. Such sifts are covered with a special protective film that makes them durable. There may be different colors.

- Plastic. Durable with a term of use equal to several dozen years, but fragile. Spring icicle, falling from the roof, leaves a hole in low tide. In addition, the price is a bit higher than the metal.

- From galvanized metal. This material is available, durable, easily cuts. The workpiece of it is simply without much effort to give the desired form. The main disadvantage of any metal is the subject of corrosion proceedings. In addition, they are more expensive than metal.

- Copper. Films from copper are now not very popular, but used so far, for more, in the construction of multi-storey houses. But such fetches are difficult to install, they need special processing before mounting.

- Concrete. Such lowers are quite heavy, so they are used, mainly for the foundations of fences and fences.

The so-called, radial flows for the foundation repeat each bending to the building, as can be seen in the photo.

Preparation, manufacture and installation of siblings for the foundation

Preparatory activities

- Survey the walls, look for cracks and other traces of destruction.

- Correct such flaws with water-repellent construction gels or facade putty.

- Swipe thermal insulation activities if such are provided for by the project.

- Make the desired measurements of the size of the foundation.

What do you need?

- Hammer

- Scissors for metal (knife)

- Pastern

- Rubber Kiyanka (or Wooden)

- Perforator and drill

- Construction chopping cord

Today it is easier to buy any fits in specialized stores or on the market. But not always ready-made products are suitable for a particular construction project. Sometimes the specifics of the buildings or the preferences of the owner require the production of protective structures to order.

In the manufacture of ties there is nothing supernatural, which a person who has at least some skills in carrying out repair work (the use of hammer, drill, etc.) could not be mastered.

The process of manufacturing treads for the foundation with your own hands

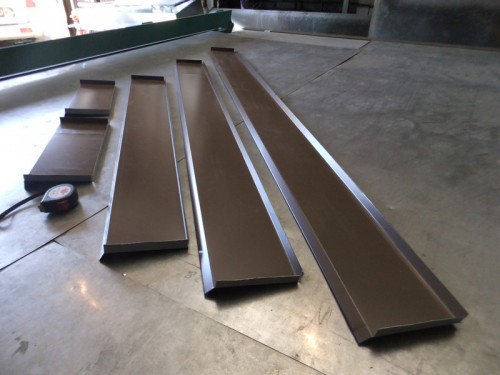

- Metal sheets or other material cut into strips of the desired width.

- Make markup in level.

- Put the workpiece on the corner and, tapping, give the necessary shape. From the side in contact with the wall, the bending is narrow and directed upwards. From the opposite side - a wide strip bend down.

Length is equal to the length of the entire foundation (basement). The size of the product width varies: narrow - to protect the foundation and wider - for the base.

Installation measures

Before mounting, mark the points of contamination with the wall.

- Determine the degree of slope by means using a level.

- Make markup.

- Note by applying a folding cord and a special coloring substance for marking cords, installation line. The painted twine for this is fixed in two places in the stretch. Pull in the center and let go, getting a flat line on the wall. On this notice and focus, mounting the sampling.

What to pay attention to?

- Carefully tighten the fasteners, avoiding the distortion and the transfers.

- When the billet from the metal with a polymer coating is not knocking on an unprotected surface. Place under the hammer rubber or felt "shock absorber" to mitigate the impact. Otherwise, it is easy to damage the protective polymer layer.

- Single should not be longer than 5 m

- Getting Starting with the arrangement of the ties only at the end of all other construction and installation work, to avoid accidental damage to the structure.

- Preparing the holes for fastenings in the wall, simultaneously mark their location and on the billet.

- With the arrangement of buildings from a tree in the array, cut the grooves in which the unscrewed, in contact with the wall, the side of the low tide. The board, subplated, will provide additional stiffness of the structure.

- To the measurements, proceed after the arrangement of the facade crate.

- The gap between the tint and wall is isolated by a sealant.

- To enhance the waterproofing effect between and the tump and the foundation, lay foam plates, or blend the resulting clearance of the foam for mounting, removing its excess.

Remember that all the production and installation measures are aimed at strengthening moisture insulation of the foundation and the building as a whole. Salves must be made so as to maximize it efficiently to remove the stormwater from the building.