How to build a staircase on the second floor Ladder,Construction

In our daily life, a two-storey house, an apartment, a hotel or a restaurant, you can not meet so rarely. Such buildings occupy a smaller area of \u200b\u200bthe site compared to one-storey with an equal total area of \u200b\u200bthe room, so every year, two-story buildings are becoming increasingly popular. In order to comfortably and safely rise from the first floor to the second - the staircase is necessary. We will tell you in this article about how to make such an engineering design in this article.

Content

Classification of stairs to the second floor

Preditly make a staircase to the second floor - this is a very responsible and painstaking job, requiring relevant knowledge and skills. First of all, such a design should be sufficiently strong and convenient to operate, and with all this, have a beautiful and spectacular look. Your staircase can serve you for a very long time, if to the process of creating it to approach with special enthusiasm.

Before proceeding with the case, you must first figure out what kind of design you need. The choice is suitable limited by your financial capabilities and free space for its placement. An important role is also played by the aesthetic component, which is largely depends on the architecture of the room as a whole.

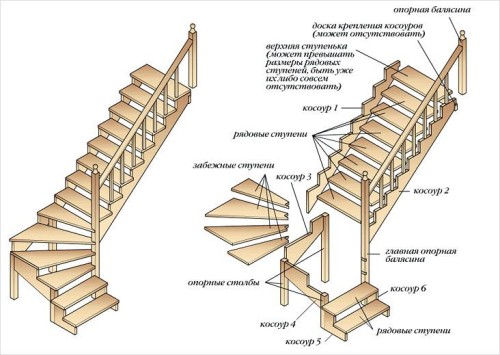

The staircase consists of:

- alternating inclined parts with steps (marches);

- horizontal parts (platforms).

There are several types of stairs to the second floor:

- form: straight, swivel, screw, rectangular;

- production material: metal, wooden, stone, reinforced concrete, combined;

- by the location of the marches on the staircase: single-hour, two-day and three-day;

- in the direction of lifting the march: Right (clocked clockwise) and left (lifting counterclockwise).

It does not matter what material the staircase is made and what kind of construction it has, the main thing is that it meets such basic requirements:

- Limit safety when lifting and when descent.

- Reliability railing.

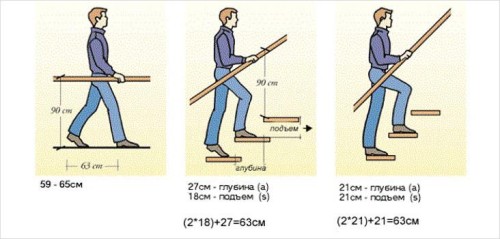

- The size of the steps matches the most comfortable lifting and the length of the step.

- Good ladder illumination.

Consider in more detail the most popular types of stairs to the second floor.

Spiral staircase

The main advantage of the staircase of this type is that there is no need for its installation. It looks very compact and convenient in the movement of one person. The design of such a staircase must be as reliable and durable as possible, so a person without a certain experience in the installation of screw stairs to cope with its assembly and installation will be quite difficult. The disadvantage of such a staircase is the impossibility of lifting on the second floor of heavy and volumetric items, such as furniture or large household appliances.

The steps of such a staircase have a trapezoid shape and are attached to the bearing rack, which can be made of wood or from metal, depending on your preferences.

Marshagian staircase

This design is most common in construction. If your room is large and space allows you to install a wide staircase, we advise you to place exactly the route. It is very convenient in movement down and up from the floor to the floor. Typically, the marching staircase includes up to 15 steps, if there are more of them, then it will be a little difficult to climb on it. If nevertheless, 15 steps can not be limited to, the staircase must be divided by a platform with a width of a march, and the length of the human step. Such stairs are single, two, three- and multi-size, straight or rotary, coordinates, theettive and on the air, are located along the wall or as an independent design in any part of the room. Marshic stairs to establish much easier than, for example, a screw.

Combined staircase

The staircase on the second floor can be not only screw or not only in Russia, but also consist of a combination of these two types of structures, for example, a marching staircase may include the elements of the screw and vice versa. During the construction of this type of stairs, a certain experience and skill are required.

Stone staircase

In the stairs of this type, the stone is used only as a facing material, because the supporting structures are mainly consisting of concrete blocks. The advantages of stone stairs are fire resistance, a fairly long service period and reliability.

Metal staircase

Nowadays, metal stairs indoors look stylish and modern. Here the metal can serve not only as decoration, but also as raw materials for the supporting structure. The designs of this type are extremely durable, durable, they will fit into absolutely any interior, from the classics to High-Tek. The metal staircase can be easily supplied with wooden steps or stone finish.

Staircase made of concrete

This design must be installed in advance, during the construction of the building itself. If the room has a small area, the ladders from concrete are installed between carrier walls, and if the room size is quite large - the staircase can be isolated as a separate part of the interior.

Staircase from a tree

Wooden stairs on the second floor at the present time are the most popular and relevant. Make a staircase to the second floor of a tree is much easier than from a stone or out of metal, because this natural material is very well processed. In the painted state, the wooden staircase is suitable for any room and any interior. This design can be constructed from one type of wood, from wood of different breeds, from simple or elite wood. Anyway, the wooden staircase will put the home atmosphere and comfort to the room. The advantages of ladders from the tree are obvious, but the flaws may be considered the creak of steps, which can not be avoided during installation and the need for periodic staining of the ladder.

A variety of materials, a variety of designs, a variety of staircase designs on the second floor. Photos of some interesting design solutions that you undoubtedly appreciate the appreciation are below:

How to build a staircase to the second floor with your own hands

So, before proceeding with the case, it is necessary to determine the type of construction and the material for the manufacture of the stairs. Then hold preliminary measurements and calculations, create a drawing or a 3D model of the design, on which you can see the location of the stairs in your room.

The first stage in the construction of the stairs to the second floor is the manufacture of details for it. Our staircase will be one-time wooden, so we need a quality tree without cracks, deformations and gray areas, with normal humidity, smooth, without bitch (or with minimal quantities) and roughness. It is best for us to be planed wood.

How to perform calculations

- To determine the size of the future staircase, it is necessary to measure the distance from the floor to the ceiling, given the thickness of the overlap - this will be our first value - height. Suppose it will be 2.7 m.

- The number of staircases can be calculated by the ratio of the height of the stairs (2.7 m) to the optimal height of the steps (18 cm or 0.18 m). It turned out we have 15 steps.

- To calculate the required surface area of \u200b\u200bthe floor to install the ladder, it is necessary to determine the magnitude of the length of the projection of the stairs to the floor plane. It is calculated by multiplying the width of the sticking (steps) on the number of steps. For the width of the sticking, we take the optimal, 25 cm (0.25 m). As a result, we had 3.75 m.

- To determine the length of the span, the Pythagora Theorem is used: where the hypotenuse is the length of the staircase, the first catt is the length of the projection of the ladder on the floor plane, the second catat is the height of the stairs. Thus, the square of hypotenuse is equal to the sum of the squares of the cathets, and the length of the stairs in our end should be 4.62 m.

Production of parts for stairs

All necessary calculations are made, go directly to the manufacture of parts for the future staircase.

- We take a wooden bar of 14 to 6 cm, we need it for the production of two cosomes (beams under steps), a 3-3 cm thick board for the manufacture of steps and a 2.5-3 cm thickness board for creating risers (parts of the stairs located perpendicular to steps and adjacent to them, determining the height of the steps themselves). The length of the steps can be chosen any, based on the size of the room in which the staircase is installed. If the boards have a smaller width than you need, you can adjust them to the required size, using instead of one wide two narrow, connecting them together with a special glue or furniture brackets. The brackets are not further than 15-20 cm from each other. To connect the boards with maximum accuracy without gaps, it is necessary to put a little on the edges in the joints of the placle.

- We try on and customize the details of the stairs, then we clean and grind them with sandpaper, especially carefully cleaned the ends. Incorrect surfaces of each wooden part with special glue (carpentry or PVA) and combine with stainless steel screws.

- Before assembling the design of the board, the vessels is missing or twice covers their hot oil. After doing this procedure, the tree is placed several times with a transparent varnish. The places for the coating of glue are closed with painting scotch, in order to protect from varnish, olifes or verses. Such processing of parts contributes to long preservation of the ladder of its original view and strength. Wood ability to resist moisture and pests increases several times.

The staircase created by this technology is somewhat cumbersome, but at the same time very simple in manufacturing and installation. For its production you will not need any special skills and tools, and the result of your work will please you very much and very long.

Stairs with mortise steps

If still, your desire is to create a more elegant design, you can make a staircase and in another way using mortise steps, and not overlays as in the previous version.

In our work, we will need to the previous set of tools. And the chisel is also, and the assembly is carried out on the bolts with a semicircular head and a slot to the slotted screwdriver of a large width.

- We begin with the fact that drilling through holes 0.9 cm in diameter in the Kosher in the center in the location of the steps.

- Insert the finished step into the right groove and put the label at the end of the stage.

- The step is removed in her end drill a hole in order to fasten the turbo house.

- The step is inserted back into the groove and fits the bolt to the turbomouff.

In this design, the staircase of the joint of wooden boards can not be lubricated with glue.

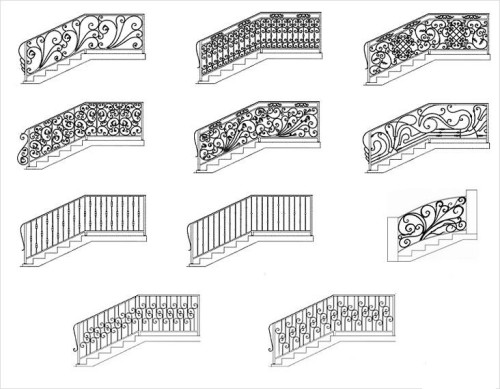

Creating peril

For the manufacture of stair railings, bales and handrails are used, which can be bought ready. Optimally, each stage is installed on one balaasine and screw them with their steps by self-drawing, setting in places of fastening the plug. The same applied with railings, fasten them with self-draws from the bottom.

What instruments are needed

What instruments we need to have in our arsenal for the manufacture of this type of stairs:

- Yardstick.

- Carpentry.

- Simple pencil.

- The usual line is not less than 0.5 m length.

- Drill (or Kollet).

- Hacksaw with large teeth and hacksaw with small teeth.

- Set of screwdrivers (or screwdriver with a set of bits).

- Chisel.

- Small hammer.

- Plane.

- Paper for grinding (coarse, mediterranean and fine-grained).

- Gloves for work.

Staircase on the second floor: video

A visual example for making a staircase to the second floor with their own hands can be this video:

We very much hope that this article will help you not only find the optimal design solution when choosing a staircase to the second floor, but also to make such a design at the minimum time and strength costs. You will definitely get the most spectacular and most reliable staircase, which will be simultaneously a convenient device for lifting and descent and undisputed decoration for your interior.