Steam generator with your own hands Climate

Purpose of the steam generator is to produce water vapor in the required quantity, which is required for bathrooms. Wet air is a necessary condition for bath procedures. The cost of such equipment can be several thousand dollars, which makes it think about how to make a steam generator with your own hands. The information set out in this article will be useful.

Content

Steam generator: characteristics and design

The size and weight of this device is not large: it can be installed in any place even a small steam room. One person will be able to transfer it. The steam generator from the following elements:

- evaporation chamber;

- nozzle;

- heating elements (Teni);

- flavoring.

Such a design for the simplest device for the production of steam. The circuit of the steam generator is more complex consists of (optional):

- control panels (remote element);

- temperature sensor;

- steam pipes (in case of installation outside the steam room);

- plumbing pipe with a locking valve;

- drain pipe;

- manual or automatic drainage valve;

- power cable.

The evaporation chamber material must have heat resistance (withstand temperatures up to 5000 ° C). For a small room (up to 4 m²), the steam generator can serve as heating equipment.

How to make a steam generator for a bath

Preparatory stage

The homemade steam generator is the best solution for those who cannot afford the factory production device. It is necessary to purchase an old propane cylinder of a suitable size (depends on the planned performance) and prepare it as follows.

- Fully empty a balloon, for what you need to open the valve, release gas.

- Unscrew the valve, turn the balloon and merge the gas condensate.

- Thoroughly wash it from the inside with the help of an ordinary household chemical for dishes. The smell of gas after that can not be felt.

- Wipe the cylinder from the inside with a dry cloth and give it to dry completely.

Installing Tanov

To work, you will need a welding machine, with the help of which the fastening for the Balon is welded to the body from the cylinder. The design of the attachment should allow the heater dismantling to replace it (or repair) and the installation.

The power of electric Tan is chosen based on the calculation of 10 liters of water - 3 kW. The steam generators of this type are more convenient than wood-haired, especially in the conditions of the ardent space of the nursery bath.

Tubbing

- Four tubes with a diameter ½ inches with threads and welded at the top of the cylinder.

- Using nuts to the tubes, automatics and other devices (pressure sensors, temperature) are joined.

- A tube with an attached ball valve is welded to the side part. It must be at no further 100 mm from the tip of the cylinder. The crane will serve as a pointer to the amount of water: after it starts to flow from it, the filling of the container should be stopped.

Alteration of valve

- The dismantled brass valve must be cut into two parts.

- The upper rod is extracted, the holes with a diameter of 15 mm are drilled to half thewithy.

- Cutting thread.

- A ball crane for the release of steam is installed.

- For control of temperature and pressure, the arrow measuring instruments are attached (sequentially to turn on the automation of the protective shutdown after the restricters is triggered). The load will serve the retractor coil.

Steam generator device: Some nuances

General installation rules

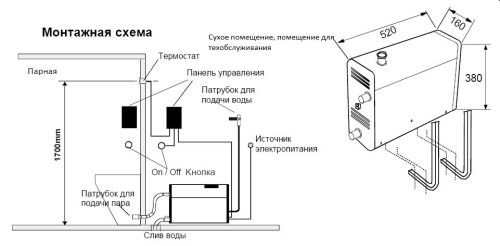

When designing a steam generator, it is necessary to consider:

- location of the device in the bath: the room must be provided with ventilation to prevent excessive humidity;

- the length of the steam pipeline should be chosen so that the condensate is not formed (it is paired along the shortest path).

Mounting Features in Shower Cab

The following rules should be followed for the shower cabin.

- Forced air ventilation should be provided (with the help of reduced voltage coolers), as well as tightness of the cabin. A special cap is installed on top of sliding and stationary partitions.

- To install the steam generator, a separate dry place is selected.

- The device must be maximally automated: in this case it will be more compact.

On the causes of the failure of steam generators

The design of the steam generator (even fully automated) is the simplest, but in some cases this device fails due to impurities contained in water. Chlorine, metal salts, iron particles cause the formation of scale on the walls of the container and pipelines.

To reduce the harmful effects of scale, it is recommended to perform the following.

- The prevention of this phenomenon is the use of water purification filters that are installed on the feed pipe.

- After bath procedures, water remains in the reservoir.

- Periodically remove the inner surfaces of the steam generator, falling asleep with citric acid, after which it is thoroughly rinse the device.

Following these rules and recommendations, you can independently make a steam generator (some options can be seen in this article), which will last for many years, provided it is properly operating.

At the end of the article, we suggest familiarizing yourself with the video tutorial, clearly demonstrating the process of manufacturing the steam generator.