How to repair the screwdriver Instruments

The screwdriver is such a tool that is needed not only to professional builders, but also to home crafts. It is indispensable if you need to collect furniture, make small repair or other home work. But how to be if the tool failed, and his host has no money for repair or waiting time? In addition, it sometimes happens that the purchase of details along with the cost of work equates to the price of the new screwdriver.

Content

How the screwdrove is arranged

Before repairing the tool, you must figure it out in its device. The main elements of the design of the screwdriver and their functions:

1. Button "Start". Thanks to it, the electric motor is turned on, as well as the revolver regulator. When you press the button to stop, the engine is closed by its contacts, and the tool starts working with the maximum power with the highest number of revolutions. If you put the button weaker, the screwdriver will also work, but with less power.

2. Rotation direction switch. Switching occurs when the polarity is changed on terminals by increasing the flip contacts when you press the button.

3. Electric engine. It consists of a housing, magnets and armature and brushes located on it. Usually the screwdriver engine is collective, single-phase.

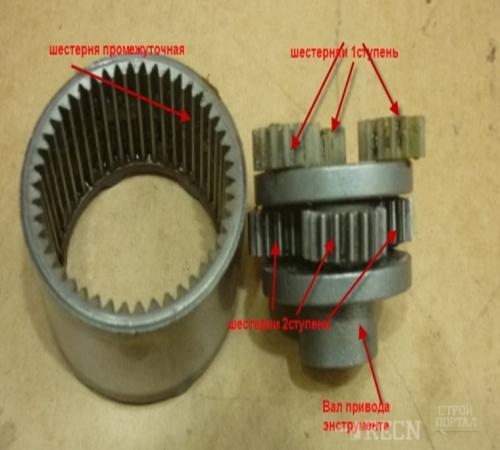

4. Reducer. It converts high turns of the electric motor shaft into low rollers of the shaft of the cartridge.

5. The tape regulator transmitted to the screw. Most often, the design of this element allows you to choose one of the sixteen tightening rates. Due to this, it appears the possibility by selecting the speed to tighten the screws on fragile materials, without damaging them.

The most common breakdowns of the electrical part of the screwdriver

Most often in the electrical part there are the following faults:

- screwdriver ceases to turn on;

- the rotational direction switch does not work;

- the revolt regulator does not work.

1. If the tool does not turn on, the first one must check the battery, in case it is simply discharged. If the reason is not in this, then the screwdriver should be tested using a multimeter.

Measure the battery voltage. It should not be lower than the figures indicated on its housing. It can be understood for two reasons:

- faulty battery;

- faulty charger.

To check the fee, connect it to the network and check the idle multimeter. The voltage on the terminals should exceed the nominal specified on the device body, for a couple of volts. If it is missing - charging is "to blame". Repair the charger for a screwdriver without special knowledge of electronics will not work, so it is better to purchase a new one.

If it is working in the battery, then, first of all, its housing should be promoted. After that, carefully examine all the wiring, especially in places of connection with each other. Perhaps somewhere they simply combined thanks to the poor-quality soldering. If they are intact, check the multimeter of the voltage of each element. It should be 0.9-1V, not less. Those elements, voltage in which will be less, have to be changed. Before repairing the accumulator of the screwdriver, we should weigh the level of your knowledge and skills, otherwise it may turn out that the device will be finally spoiled.

If the check showed that charging and battery in working condition, it means that the problem lies in the screwdriver itself - it is necessary to disassemble it.

Battery terminals are connected to the two wiring button. Using a multimeter, measure the output voltage from it. If it is present, pull out the battery and, using the "crocodile" clamps, shorter its wires. Now measure the resistance in OM at the output of the button. This indicator should strive for zero, it will mean that the button is proper. If the testing device showed a break, then the button will have to be either changed or repair. If the malfunction arose due to the fact that the contacts were burnt, a sufficient measure would be cleaned using ease and subsequent assembly. Well, if the matter is in something else, it is easier to simply replace the button.

2. If the rotation direction switch does not work, also use the multimeter. Put it on its probe on the button input wire, and the other either to the output of the button or the contact of the electrical engine. Press the switch button, see what it shows. If some resistance is recorded, this means that this node is working if the reaction is no - the conductivity of the contact contacts is violated. Eliminate this malfunction should be in the same way as in the previous paragraph.

3. If the electric motor operates at a maximum, and there is no revolutions adjustment, then there may be several reasons:

- fault buttons;

- the regulating transistor failed;

- worn brushes.

To begin with, it is necessary to estimate the status of the brushes. The fact is that over time they are erased and this is precisely this sometimes causes failures in the work of the instrument. If it is established that the brushes are in order or recently changed, it means that the problem is in other parts of the engine. To check it out, disconnect the wiring from the button and measure the resistance on the contacts of their mounting. If this indicator is close to zero, it means that the winding is cut - the engine is necessary or rewinding.

It is also necessary to establish whether the anchor winding is well. To do this, measure the resistance of the adjacent collector plates. Moreover, "0" will be the norm. And in case of exceeding this indicator, it should be repaired or replaced anchor.

The most common breakdowns of the mechanical part of the screwdriver

Violation of the work of the mechanical part of the screwdriver is often accompanied by the following "symptoms":

- in the included state, the tool makes earlier absent outside sounds;

- the screwdriver strongly vibrates, the bout of the clamping cartridge is observed;

- when you turn on the tool encourages.

1. The appearance of unnatural sounds can mean that or sleeves, or the anchor bearings were worn out. To install this for sure, you should disassemble the engine and inspect these parts. Anchor should stand smoothly, turning easily, the slopes and friction are unacceptable here. If the opposite picture is observed, then repair the screwdriver does not take much time and effort. It is only necessary to purchase the desired detail in the store and install in place old.

2. Sometimes trouble happens to the gearbox. Most often such:

- the shaft twisted;

- the working surface of the gear was worn out;

- the support sleeve or bearing was worn out;

- they broke the pin to which the satellite is attached.

To eliminate all these malfunctions, you need to change the broken structural elements.

Repair of screwdrivers requires marginal attention and consistent actions during assembly and disassembly. Inactivity in this business may entail additional troubles and malfunctions in the instrument.

Before repaired the screwdriver, you need to think and weigh, whether there will be enough knowledge and skills. If not, it is better not to risk and seek help in a service center.

Tools of all known brands are arranged approximately equally. If the homemade sample does not know how to repair the Mcita screwdriver, it is quite possible to use the instructions described above. To the question "How to repair an intercol screwdriver, the answer may be the same.

Screwdriver repair, video:

New comments

Add a comment

To send a comment you need authorize.

hello. Help please where you can buy a spare parts for Schupurovet.