Wood Furnaces - Fireplaces of Long Burning For Dacha With Your Hands Climate,Useful advice

Small ovens of long combustion that work on firewood are an excellent alternative to gas and electrical heating devices. In places where traditional heating systems make no sense, for example, in garages or dachas, small ovens will become an excellent solution.

Content

Currently, dozens of different bourgeoke designs have been developed, with different fuel combustion schemes and heat removal. A small cost of manufacture, unpretentiousness to the use of various fuels made metal furnaces quite popular. It is especially worth noting heating fireplaces, which, along with heat generation, carry aesthetic load. Fire is one of the things to which you can watch forever, relaxing after a hard hard day.

One of the problems using wood-haired furnaces is their low level of automation. If the owner may not think about the operation of a gas or electric boiler for a long time, then loading fuel into wood ovens must be performed constantly. It's not entirely convenient if you have to get up at night to throw firewood into the furnace. Currently, several designs of long-burning furnaces are developed, which can work without additional downloads for 12-18 hours. About how to make a furnace-fireplace for giving with your own hands - further in the article.

Options for low-cost fireplaces for giving

The designs of wood stoves are quite a lot, from small bourgeoque, the production of which even at home does not occupy a lot of time and means, to the fireplaces of long burning and bulers, the designs of which are quite complex.

- Bourgehogs. Simple ovens, which can be made of any girlfriend, be it old steel barrels or cuts of pipes of large diameter. They are distinguished by simplicity of the design, high fuel combustion and low efficiency. Usually burzhuyki installed in places where the heated area is not too big as the time of its work. It can be garages, warehouses, sheds, etc.

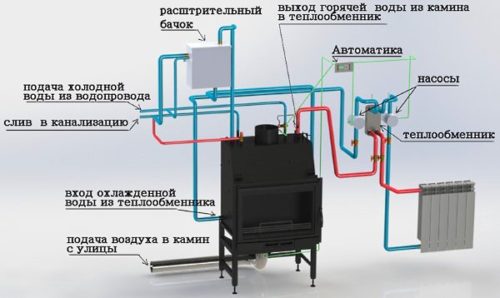

- Buleryan. The design of such a furnace resembles a bourgeitogo, however, to improve convection, its casing is rejected by several pipes. Due to the heating of air in the pipe, it becomes easier and comes out, with the cold air due to the vacuum formed sucking into the pipe. Due to the improved convection, even with small oven the oven itself, it can be heated by large areas. Booleries are used mainly for industrial premises. However, sometimes they are used in private homes, while mounting the air duct system in the building, or a liquid heating system with forced circulation. True, for this you will have to do the oven pipes to do a full-fledged water shirt.

- Furnaces of long burning. There are wood-burning fireplaces of long burning relatively recently. The principle of combustion of fuel in them differs from the above structures. If the bourgeois and buleries are lit down from the bottom, as the air is fed through the located at the bottom, then in the crops of long burning, its feed occurs from above. Due to this, the combustion of coal or firewood occurs. Such furnaces are made high with a massive loading hatch, due to which the combustion process continues for quite a long time. Another important feature of these structures is the possibility of afterburning combustible gases, due to which their efficiency increases. Such furnaces are perfect for giving, since the loading of fuel in them can be carried out in 10-16 hours depending on the volume of the furnace and its height.

Wood Furnaces - Long Burning Fireplaces - Design

The furnace consists of several main parts:

- The furnace is a place where fuel burns directly.

- Infused - the space from the bottom of the furnace, thanks to which the thrust is created.

- The cast iron grate - the lattice between the confusion and the furnace, on which fuel lies during the burning.

- Water tank. The tank made of steel, most often stainless, which is installed above the furnace. Usually the smoke tube passes through it.

- Chimney. It serves to remove burning products outside the room.

- Capacities for stones. Quite often is installed between the firebox and water tank. Stones can maintain heat longer, which increases the design efficiency.

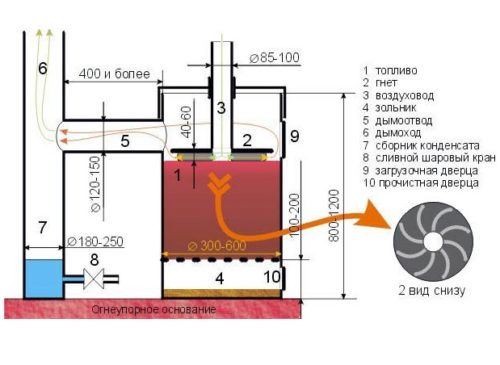

The main design of the ovens of long burning, which is used for home production of heating devices, was borrowed from the boilers of Stropuva. It is in a large amount of firebox, which loads fuel. The furnace window is at high height from the floor. At the beginning of the combustion of fuel after the ignition, the process proceeds with a large air supply through the firebox door. After the firewood or coal is spoiled, the access of oxygen through the furnace stops (its door closes tightly) and serves it through a special tube on which nozzles have. By pipe, air passes through the upper furnace, into which the hot flue gases come, due to which it is heated to a temperature of 400 ° C. Due to this temperature of the incoming air, the combustion process occurs with a large efficiency. When the furnace is output to the operating mode, the temperature in the combustion chamber increases, which contributes to a deeper joy of pyrolysis gases. Also in this chamber is an element that switches the unit from work on firewood - to work on the corner or coke.

Unlike the factory unit, homemade fireplaces for the cottage of long burning do not have a water shirt, so they cannot be used for heating large houses, but for giving they come perfectly. Another significant difference between the homemade stove from the STROPUVA boiler is the design of the air supply system in the furnace.

The most successful design of the self-made ovens of long burning is bunch. Experimed by the designer of this heating device, the most optimal parameters picked up to achieve maximum efficiency.

In order for a long-term burning oven with their own hands, it worked perfectly, with its production it is necessary to observe the structural parameters.

So, the ratio of the height of the furnace to its diameter is of great importance for the normal combustion process. This ratio should be from 5: 1 to 3: 1. If the diameter of the unit is greater, then the burning of fuel will occur only in the middle. This will not only lead to greater fuel consumption, but can cause a breakdown of its mechanism. Air supply in the Furnace Foren for the cottage giving is made through a metal pancake, which has a look like a piston. It is connected to the pipe through which air is served under it. With uneven burning, it can be taught from temperature and just jammed. The small diameter of the furnace will be the reason for the lack of air, because of which it will simply begin to "choke." The optimal diameter of the unit is from 350 to 750 mm.

Depending on the features of the furnace, the thickness of the metal is selected for its manufacture. In principle, it can be made of a pipe with a thickness of the wall from 3-4 mm. Some craftsmen made bubfoni from old metal barrels, however, due to the small metal thickness, such a design is difficult to call reliable.

The most common material for the manufacture of metal furnaces is the pipe rental of the average diameter of more than 500 mm, and the wall thickness of at least 8 mm. The fact is that the construction of a tubular furnace is a less labor-intensive process, in comparison with the designs of sheet metal due to a smaller number of welds. In addition, due to the rounded form, the furnace heatsily heats up evenly, which reduces the likelihood of the rogs in its case. With such a furnace design, if you do from the pipe, you can easily mount the water heating tank, then the entire installation will be monolithic.

The main element of the design of the furnace are the dimensions of the air supply disk. Its diameter should be 5% less than the inner diameter of the furnace. Such a gap will ensure optimal burning of fuel. So, in the case of too heavy item, the fuel can be strongly compressed, which will make the combustion process uneven. With too easy disk, it is possible to ignite the lower fuel layers and the occurrence of the reverse thrust effect, which can lead to sad consequences.

Distribution ribs are welded at the bottom of the disk. They direct the air flow on the sides, which comes through the pipe. If the height of the ribs is at least 10% of the diameter of the furnace, then the optimal oxygen access for fuel burning will be ensured. Ribs can be made straight or curved in the form of blades. Such a configuration, as practice shows, more efficient. The pipe supply pipe into the furnace to which damn is welded, should be a diameter of at least 75 mm. With a smaller cross section for good burning, it will not be enough.

During the construction of this design, special attention should be paid to the diameter of the chimney outlet. It is calculated depending on the energy estimation of the furnace. The latter is calculated as a mass of fuel multiplied by the specific heat of its combustion, and the mass, in turn, is determined by multiplying the volume of the furnace on the specific fuel loading coefficient. To obtain the diameter of the emerging nozzle, it is sufficient to multiply the energy estimation of the furnace to the coefficient of 1.75.

Manufacturing and installation of a latter burning fireplace

Depending on the parameters of the furnace, the necessary blanks are made of metal. Welding work should be carried out very carefully. There should be no gaps in the furnace housing. Otherwise, there is a high probability of penetration into the premises of carbon monoxide gases. After the completion of the work, it preparations of the place to install the furnace. The principle of operation of long-burning furnaces implies fuel hurning at the bottom of the heat chamber. This means that at its bottom there will be a rather high temperature. Therefore, such models of furnaces should be installed only on the prepared foundation, regardless of whether it has legs.

The chimney of the fireplace furnace for the extension of long burning should have a height of at least 4.2 m from the horizontal nozzle until its end. This will create the necessary traction. The horizontal pipe itself, which connects the nozzle with chimney, should be a length of no more than 0.4 m. However, it is worth remembering that too short distance from the chimney to the oven may disrupt its balance.

To remove condensate chimney from the pipe, its lower end is brewing and installed a ball valve.

Furnaces Fireplaces with water contour for giving: Photo