Device of concrete wells Construction

On a private site, during the construction of a house or cottage, the issue of water supply often arises. Options for solving this problem There are several and one of them is the installation of a concrete well. Depending on the material used for the construction, the wells are divided into several types. The design of the well made of concrete is favorably different from other species in terms of strength, durability and sanitary and hygienic standards.

Content

Features and device of monolithic wells

The well concrete is divided into two types - the prefabricated and monolithic. Special distribution today received structures of a monolithic species. Concrete, which is a material for mounting wells, is a stone of artificial origin. Get it out of a mixture of rubble, cement, sand and water as a result of a hole. Prefabricated structures are made by mounting the rings from concrete or reinforced concrete material.

A well construction is built by solid concreting method. In order for the design to have greater strength, the mass after the fill immediately needs to be sealing. This is done by means of a special unit. This device acts as follows: it transmits mechanical vibrations to the mass of concrete, as a result of which the composition is sealing.

The method of structures of the monolithic view of the well is as follows:

- Beginning the work process is needed from the preparation of the mine up to 1.5 meters. The depth of the mine, if necessary, can be more and more, but for safety reasons, work should be carried out in parts and it is mandatory to strengthen the walls as shut down.

- Next, to facilitate the workflow on a concrete mount, you need to install a cutting shoe, the ring of which will be required to install the reinforcement frame and two formwork. It is installed next to the deepening deepening. The formwork differs in its type - the outer formwork is a solid product, and the inner consists of the bands.

- Then the design must be pouring into a concrete composition and omit into the prepared recess.

- Next, the reinforcement frame is increasing and an internal formwork is exhibited.

- After concreting the second rings, 1 meter in height, the deepening of the mine should be evenly undermined on all parties.

- Next, the workflow continues by increasing the reinforcement and formwork, accompanied by concreting.

- When the well reaches aquifer, you should form a bottom filter for water from sand and rubble. In the upper portion of the well, above the ground surface, equipment for a water set, for example, a pump is installed.

- Construction of a monolithic type well takes longer than the installation of the collection structure, but in this case the use of lifting equipment will not need. In addition, in this way, both traditional round structures and wells are concrete squares can be made.

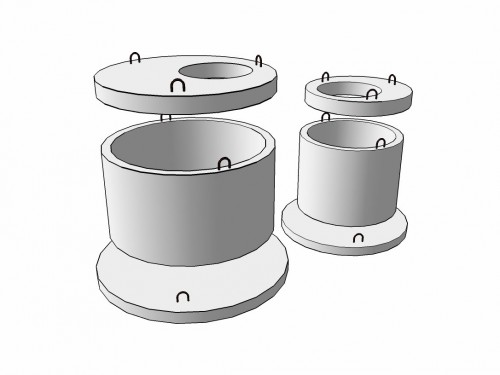

Collened well

Construction of the prefabricated design is relatively with a monolithic well takes less time and the process itself is more convenient. Such a well-being concrete at a price is obtained by budget, and performance features meet high requirements. Formwork in this case is mounted from two collapsible rings that need to be installed in another one. Such fragments can be wooden or metal. You can purchase ready-made rings of factory production, and you can make them on your own.

When the device, a well made of concrete rings uses special forms that are two cylinders. Each of these fragments has a different diameter. The concrete composition is poured into the gap, which is formed between these cylinders. To increase the density of the rings of concrete for the well, the crushed stone of granite is used.

Installation of this type of construction is carried out in the following way:

- Before starting work, it is necessary to align the bottom in the pit, then omit the ring. This is the first ring, which in diameter should be more followed by 5 cm.

- On the underside of such a ring there is a knife with pins. It provides easier penetration of the product into the soil. With a weak soil, the use of such a knife is not necessary.

- At the aquifer under the lower ring, the stove is placed from reinforced concrete material, then the walls of the well are undermined.

- Next, the ring on the edges must be hooed in the ears or brackets located on the sides of the vertical way, and omit into the deepening of the future well.

- Subsequently, the ears and brackets are cut with a gas cutter. But you can do without this action if the ring will be a sinus with a hole that goes out and through which the sinus sinus is filling. To fasten the rings of the concrete well rectangular use steel brackets.

- Next, on the top of the circle, it is necessary to put the seal. It can be any material with a fibrous structure, such as a rope. The purpose of this action is the creation of a safety barrier in order to prevent the flow of polluted water into the well. As a result of the use of sealing seals between rings expands. For this reason, one of the rings should be round, and the other is ellipsoid. The length of the ellipse is two diameters of the bracket, regardless of the size of the concrete well.

- By installing the second ring you need to clean the internal seams, brackets or ears with water. It is necessary to wait for the concrete to dry and then fill the seams with cement mortar.

- External seams are also sealed with such a solution, but after installing pipes.

- To achieve the strength of the design, it is recommended to strengthen the rings by brackets on both sides. To do this, the components with oil coloring composition having water resistant qualities should be treated.

- In the absence of the necessary grooves in the rings for the bracket, they should be drilled using the electric drill.

Concrete Mix Production Rules

The volume of water added to the mixture determines the consistency of the solution. So as a result of adding a minimum amount of fluid, we will get a thick hard composition, which will increase the weight of the concrete ring for the well. When adding a slightly larger amount of water, the solution will acquire plasticity, it will become not so thick and more movable. If the composition is a sufficient amount of water, it turns out the cast movable mixture, which will fill in the form of gravity. All three types of mixture requires a different degree of seal.

Making concrete solution, such features should be taken into account:

- It is necessary to ensure that the amount of water does not exceed the necessary norm. Otherwise, the density indicator will decrease, and the mixture will begin to settle. It is certainly possible to understand whether a mixture of concrete raw materials is enough by applying a special cone. This design element has two knobs in the upper part, and two stops are located in the lower cavity. They are provided for the Master to become on them. In such position, the cone should be tightly pressing the steel sheet or board.

- To determine the plasticity indicator of the composition, it is necessary to carry out the following procedure:

- place a cone on a pre-moistened sheet or board;

- next, this fragment must be fully filled with three layers of concrete, each of which needs to be gently pierced several times;

- then make a cone and arrange it next to the mass;

- in the next, we put a rack over it on top of it and look at the distance that is formed between the rail and the upper part of the mass;

- next, we focus on the following indicators: the rigid mixture should settle for 2 cm, the mass of the semi-rigid structure is settled by 2-5 cm, and plastic - by 6-14 cm, cast - by 20 cm.

When building large structures of concrete wells, where the armature has a rare location, the most suitable will be the use of a mass of tough consistency, as well as half-rig. The plastic mixture is more appropriate in the construction of small-sized structures with a frequently located reinforcing frame.

Concrete mass strength reduces dirty raw materials. Therefore, gravel, sand, crushed stone before applying should be rinsed. In addition, you need to trace the material to be ridiculous. This must be done so that the amount of emptiness in the mixture is minimal. Determine how much emptiness can be as follows:

- This will require a bucket, a capacity for example 10 liters. Fill it with a bucket of the composition, after which you need to pour water and pay attention to its volume.

- If 5 l placed in the capacity, this indicates that the amount of voids of the mixture is 50%.

- The valid index for gravel is 45%, for sand 37%, for rubble 50%.

Regarding the amount of dry mixture, the concrete mass in the finished form is slightly reduced in its quantity. So out of 1 m 3 Dry composition you can get 0.7 liters of concrete solution. This circumstance should be considered before preparing the composition to obtain the diameter of the concrete ring for the well of the desired size.

Rings made of concrete or reinforced concrete are made in a height of 1 m, and also have a diameter of the same size. The wall thickness of the ring is 10 cm. This is the optimal thickness in several indicators:

- first of all, the consumption of material in this case will be quite economical;

- it will not affect the strength of the product, providing the necessary space to place the reinforcement.

Note that the rods 8-12 mm in diameter, as well as horizontal rings, the diameter of which are 6-8 mm, are used for reinforcement rings.

Conclusion

Concrete wells, which can be used in the national team, are quite a convenient way to ensure water supply in those places where it is impossible to connect to the centralized system. Comparatively with other materials, concrete is greater durable. Accordingly, the designs made of concrete mixture have more reliable operational characteristics. A concrete well with your own hands can be made in two ways, each of which in the installation process has its own characteristics.

The device of concrete wells and installation features can be seen on the video: