Puzzle plates (PGP): Characteristics and installation Building materials

Puzzle plates are widely used for partition devices and for facing the outer walls indoors. Thanks to the environmental purity of plates and ease of installation, the PGP serve as a good replacement of plasterboard.

Content

What are the puzzle plates

In the production of PGP, plaster and plastic additives are used. The absence of harmful impurities allows you to get an environmentally friendly material.

Gypsum puzzle plates are produced two types:

- ordinary;

- moisture-resistant (hydrophobized).

The composition of the molding mass for the manufacture of moisture-resistant plates is introduced hydrophobic additives, which reduce water absorption. Low water absorption allows you to use such plates in rooms having a humidity of more than 60%. Conventional PGPs are used in dry rooms and indoors with normal humidity.

The plates have the same dimensions and design and differ only in externally - moisture-resistant plates have a green color.

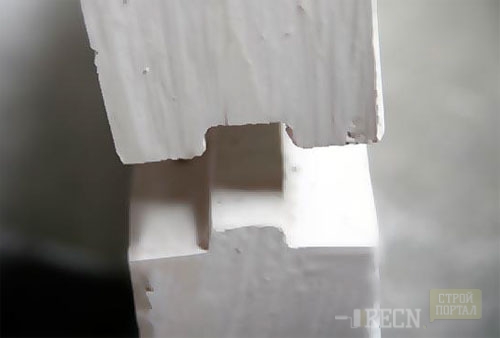

The name of the plates comes from their design - there are grooves and ridges on the ends, thanks to which the partitions are installed easily.

Both ordinary and moisture-resistant plates are produced two species - hollow and full-scale.

- Hollow boards have less weight compared to full, so it's easier to work with them.

- Hollow PGPs provide better sound insulation and have lower thermal conductivity.

- The disadvantages of hollow plates include the difficulties that occur when shelves hanging. For fastening the shelves, use special spacer dowels with a metal rod.

Buy the puzzle plates are better in reliable manufacturers who are Knauf, the Volga, Rusean. Also, these firms produce gypsum glue for the installation of PGP.

Buy the puzzle plates are better in reliable manufacturers who are Knauf, the Volga, Rusean. Also, these firms produce gypsum glue for the installation of PGP.

The thickness of the puzzle plates 80 and 100 mm with a standard size - 667x500 mm. The weight depends on the thickness and type of plates - the hollows have a weight of 20 to 30 kg, full of 30-35 kg, moisture-resistant with a thickness of 100 mm weigh 49 kg.

The price of puzzle plates depends on the type of plate and its thickness. At various manufacturers' firms, it ranges from 250 to 700 rubles.

Advantages of puzzle plates

- Speed \u200b\u200bmounting. The partition can be erected in 1 day. The construction of walls of brick requires much more time and qualifications of the master. With gypsum glue, which is used for mounting PGP work easier and more pleasant than with cement mortar for brickwork.

- Ease of operation and further operation - the plates are easily cut and drilled by an unstressed method.

- With further finish, plaster and wall leveling is required.

- To putten the walls can be started the day after it is erected.

- High thermal insulation.

- The material does not support burning.

- Easy installation of wiring.

- When the door opening device, up to 80 cm width does not require the installation of support beams.

- Plates have high vapor permeability, which allows the walls to breathe and does not prevent the formation of condensate.

- In contrast to the drywall, the PGP is not deformed when the moisture change, the walls are not afraid of flooding from the neighbors from above.

- Have high strength - 2 dowels are able to withstand the weight shelves with a load of up to 200 kg. This is advantageous distinguishes the walls of the PGP from plasterboard. When equipped with plasterboard partitions, you must think in advance where the shelves will be attached and strengthen the design with wooden bars or metal profile.

How to perform the installation of puzzle plates

When applying partitions from PGP, it is necessary to take into account that the length of the wall should not exceed 6m, and the height is 3, 6 m. If necessary, installation of partitions exceeding the permissible dimensions, the installation of a frame that is mounted on the supporting structures of the building is necessary.

Tools and materials

For the installation of PGP, expensive tools and fixtures are required. You will need:

- Gypsum puzzle plates.

- Glue for mounting plates on a plaster basis.

- Putty for gluing gasket.

- Laying from traffic or bituminous felt.

- Hacksaw.

- Capacity, drill and mixer for kneading glue.

- Level, plumb.

- Rule.

- Rubber hammer.

- Twine.

- Roulette, pencil or marker.

- Putty knife.

- Wedges for adjusting the horizontal of the first row.

Operating procedure

- Alone align the floor.

- Make marking on the floor and wall.

- Paul, walls and ceiling should be cleaned of dust and dirt. Treat the primer of the septum adjacent to the bearing wall, floor and ceiling.

- Check out a small amount of putty fugenfuller and use it with it with a gasket along the places of the septum adjoining. This is necessary for elastic adjustment. Hold the time that is required to set the putty - 30-40 minutes. After that, you can proceed directly to the installation of plates.

- Installation of plates is made on plaster glue or putty. Time to set the released mixture of 30-40 minutes. The mixture consumption is not very large. For mounting 1 m² walls, 1 kg of mixture will be required. Six the mixture with such a calculation so that you have time to work out. The speed of setting the gypsum glue or putty depends on the purity of the tools.

- For a better distribution of glue or putty in the groove, the plates are stacked up. It is allowed to lay a groove down, but it affects the quality of work. Pluckle filled plates grooves - vertical and horizontal.

- Install the first row plates. If the floor has deviations from the horizontal - use plastic wedges to align the plates. The location of the PGP in the same plane is monitored using the rule.

- Before laying the second row, saw the first plates in half - the vertical joints of the slabs of each row should be placed in a checker order. This location gives the stiffness of the structure.

- Use a rubber mallet to comb exactly in the groove previous board. Protruding from the joints immediately remove the glue with a spatula, without waiting for it dry. The width of the horizontal and vertical joints should be identical.

- When installing the last row adjacent to the ceiling, cut the slab height and grind off the edge angle. The beveled edge can reliably fill filler space between the plate and the ceiling.

- If you need to perform the doorway more than 80 cm, install a jumper beam, which will serve as a support for a row of plates above the opening. The jumper should enter the edge of the opening of at least 40 cm.

- For further decoration of the wall - putting the seams and alignment of minor deviations, you can begin the next day.