Concrete floor repair do it yourself Floors

The open floor of the concrete in the residential premises is practically not found, mostly can be seen in the garage, bath, terrace or veranda. Concrete floor apartments serves as a base for coating by other materials: wooden board, laminate, linoleum or polymer layer. In any case, situations arise when the concrete floor is required to repair. With the repair of a concrete screed, it is better not to delay, easier and cheaper to eliminate defects at an early stage. For work on restoring concrete floor, you can invite a specialist, and if the work is not too voluminous, it is quite possible to cope with our own forces, saving funds from the family budget.

Content

Where to begin?

Concrete - as an organism, only construction. Over time, it also agrees and flies. Before proceeding with the repair, it is necessary to make a "diagnosis": to investigate all defects, determine the view and volume of the upcoming repair, really evaluate your abilities and opportunities.

Repair or replace?

With a thorough inspection of concrete floor, the following defects can be detected: cracks on the screed, bulges, potholes, detachments, gaping cracks. If the concrete damage is less than 40%, then we make repairs. With more significant destruction, it is better to completely replace the concrete floor.

Typical situations

- Increased floor peel, rare small potholes and protrusions, narrow cracks. In this case, the repair by own forces will be simple and inexpensive.

- Short gaping cracks are quite simply repaired using finished repair makeup.

- Paul buggy. Alignment of such a screed is performed by a milling machine, this type of repair is accompanied by a large amount of dust.

- Long gaping diagonal or cruciform cracks require the revision of the ceiling overlap and without a feet of the floor can not do.

Tools and materials

Specialized stores have a large selection of building mixtures to restore a concrete screed. For minor work, we prepare the mixture yourself, which will cost cheaper. The composition includes: bustide or PVA, diluted with water (1: 3), a mixture of cement and sand (1: 3). All mixtures, and homemade and ready-made to be kneaded. Manually high-quality kneading, so we use a building mixer. Instead of a mixer, resourceful craftsmen use an electric drill or a perforator with a special nozzle. ATTENTION: It is forbidden to include a shock mechanism, otherwise everything will be spattered with concrete. The repair of a concrete screed will also need a spreader with a width of 1 m (rule), a Bulgarian with a diamond disc, chisel on concrete and necessarily the means of protection: respirator, glasses, gloves, deafly fastened clothes and headphones. For the overhaul of the concrete screed, the metal crooked roller will be required.

Preparatory work

Before repairing the room is fully released. First remove large garbage, then 2-3 times the floor is labeled with a wet broom. Throw and cracks after drying the floor are purged by a household vacuum cleaner. The work is greatly simplified if there is an industrial vacuum cleaner. Well, the floor is ready for repair.

Za # is a delicate matter

The strength and durability of the floor depends on the composition of the concrete solution and the quality of the knead. It is necessary to mix with a mixer. The store mixtures are diluted with water, self-made suspension from PVA. The finished solution must contain a minimum of moisture. Water or suspension is poured into a dry mixture with small portions by continuously stirring the mixer with circular motions along the tank. The time of kneading is 3-5 minutes. If with the amount of water to overdo it, it turns out inhomogeneous poor quality concrete. At the end of the mixer immediately, we have a pre-cooked bucket with clean water, turning on the tool for a few seconds.

Types of repair

All works on the repair of concrete screed are divided into 4 species, each of which has its own features of technology:

- Elimination of defects.

- Repair of gaping cracks.

- Overhaul.

- Dust.

Eliminate potholes

The elimination of the chosel is carried out according to the following scheme: the damaged part of the floor is cut as a rectangle with a depth of 20mm. The carved area is removed by the chisel on concrete or perforator, and small potholes with a hammer and chisel. The resulting flow is cleaned by an industrial vacuum cleaner and is treated with epoxy primer. With the help of a spatula, the spatula is filled with a special tool - consolit-leopard, Ivsil Render and rake or ruled. And at the end after frozen the repair mixture, grinding is performed. In the case of deep chosel (more than 50mm), the mixture is applied with layers in several techniques.

Get rid of cracks

The method of sealing cracks depends on their magnitude. Small cracks are close in this way: the crack is expanded to a depth of 10 mm using a grinder with a diamond disk. Cleared from dust. It is processed by primer (epoxy or polyurethane) with the addition of solvent R-646 (1:10). Climbing the repair mixture from epoxy resin or polyurethane and sifted quartz sand. If necessary, the 2nd layer is applied. After soaring the repair mixture, the surface is grouped.

Wide gaps are repaired by technology - "Strip". Climbing such cracks is carried out as follows: The crack is plunged at 50mm. On both sides of the crack, the grooves are cut and concrete fragments are removed. The in-depth gap is cleared of dust. It is then applied with an epoxy or polyurethane mixture with the addition of solvent R-646 or solvent. The crack is processed by the repair mixture of 1-2 layers and after solidification is grouped. If it is necessary to strengthen the strength of the concrete floor, metal brackets are used. The crack is expanded to a depth of 20mm, cross-cuts, a depth of 20mm and a width of 150 mm are applied every 200mmm. The resulting cavity is cleared and ground. The repair mixture is stacked and metal brackets are placed, then cuts and cracks are completely close to the mixture and after solidification is grouped.

Deformation cracks

This is the most dangerous type of cracks, as they can be an emergency signal. And maybe you will need the overhaul of the entire building. The dynamics of destruction is important: the crack is progressing or not. You can estimate the dynamics by the "paper" method. It would be nice two months before the repair paste on cracks with an interval of 0.5 m paper stripes. On the deformation crack, the strips will be broken during this time, and on the shrinkage gap will remain integer.

How to patch the gaping cracks?

The gaping crack is called a slot width more than 2 mm. Repair of this damage is as follows: the crack is plugged at 50 mm and expands by 20-30 mm. The edges of the cut was knocked up, a triangular flow is formed. Wpadina is thoroughly purged and processed by primer. After drying the soil into the propyl, the markers are inserted in a vertical position (thin metal rods, cycling spokes are suitable) and the gaps are embarrassed by a branded thixotropic composition using the rule. By setting the repair composition, the markers are removed (so that they are easily removed, pre-lubricate the consistent lubricant), and the seam of the former width is done by their traces. In the seam, the cord-damper is laid (VYLOTERM), on top of which sealant from silicone or polyurethane is applied.

Overhaul tie.

Overhaul screed - in fact, its replacement. This is the most expensive and time consuming of all varieties of concrete floor repair. This repair is inevitable if the concrete floor is badly damaged or the installation of a warm floor is planned. Depending on the materials used, there may be different types of overhaul:

- Floor screed from wet concrete mixes.

- Semi-dry screed from the cement-sand mixture with fibrovolock and plasticizing components and the minimum volume of water necessary for cement hydration. Selling prepared mixtures for semi-dry tie (ARMIX floor).

- Dry screed using dry fridge and drying sheet.

How the thickness of the screed is calculated

Example of calculation:

- waterproofing film - 1 mm,

- ceramzite layer - 30mm,

- reinforcing grid - 7 mm ,.

- concrete layer - 8 mm,

- mastic - 1mm,

- plywood - 9mm,

- glue - 1mm,

- laminated coating - 16 mm.

Install the screed markers

In order for the floor to be as smooth as possible, it is very important to choose and place the markers. Most often, rush markers or wooden lags are applied. Rush markers are placed parallel to the short wall: 1st - in 30cm from it; Follow-up - with an interval equal to 1/2 width of the rule.

Overhaul Screed: step by step

- Waterproofing (plastic film) with overlap in 0.5 m and overlap on the walls at 15 cm. Fixation of the joints of the scotch.

- Keramzit is spilled by a mustard roller.

- Reinforcing grid with overweight in 2 cells and an indentation from the walls of 40 mm.

- Installing markers and screed level markup.

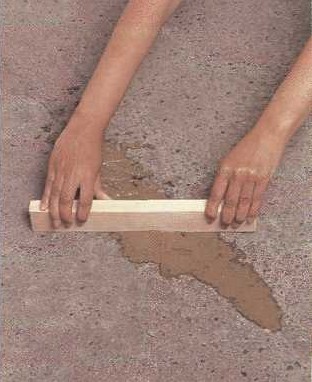

- Summary and rareling.

The solution from cement and sand (1: 3) is a portion of 10-20 liters and lay out between markers. Each serving of concrete is aligned with the rule, leading to them by markers as rails. After reclamation, one portion is embarking on the next. After pouring the solution, the markers are removed and the grooves close up with concrete frustration. Excess waterproofing film is removed after installation of the plinth.

Finishing stage

After repairing the floor, it is necessary to withstand at least 20 days, spraying daily by water. To protect against drafts, a slaining surface can be covered with a plastic film.

Dusting

The fastest and easiest of all types of repair - dedusting is used in excess sex dust and the absence of noticeable defects. The floor becomes dusty due to the wear of the surface layer or disruption of the construction technology during concreting. It should be remembered that cement dust is dangerous to human health. Special compositions are used to update concrete floor. For floors in the utility buildings, the compositions are suitable: neomer-LP, Elac-Pu, Ashford formula. When they are applied, a layer of 150 microns is obtained. The floor of the concrete in the residential premises is better to process: Grovelast-Pu, Elakor Ed, retroplates. The coating layer is 250 microns. The order of repair work on the dedication of sex:

- If you can handle the surface of the floor with a grinding machine.

- Clean the industrial vacuum cleaner or simply carefully fit.

- Brush or roller to apply a dusty tool in 2 layers.

Such restoration measures will prolong the service life of concrete coverage for many years.

The eyes are afraid, and the hands do

Concrete is an easy-to-use material, and if you follow all the hard rules for working with it, it will not let it down. And then it will be possible to say with pride: this floor is made with your own hands.