Parquet floorboard - Selection and laying Floors

Despite the existence of newer new and modern floor materials today, Parquet still did not have lost its relevance. Moreover, in recent years, an even greater interest in the popularity of healthy lifestyle and the use of environmentally friendly materials for finishing the premises has even increased.

Undoubtedly, in the matter of security for human health, parquet is practically no equal, but at the same time he has a number of other advantages. A parquet board is characterized by excellent performance, exquisite appearance and simplicity of laying, as well as many other properties. The only thing that natural wood does not tolerate is high humidity, so parquet does not recommend laying in the bathroom or in the kitchen. Today, more and more people choose the parquet for finishing the floor in their home.

Content

Features of the choice of parquet board

In order for such a floor to please you for many years, you need to pay special attention to some very important features of choice, namely:

- Parquet cost;

- external characteristics;

- Its appointment and operating conditions.

The last indicator is especially important, since the durability of the parquet depends on it. The more loads he will experience it in the future, the greater durability, the wear resistance must have this material. The quality of the parquet, in turn, depends on the tree of the tree, from which it is manufactured. The most durable is the oak and beech, a little less inferior to the tick, larch, ash, bamboo. The higher the quality of the parquet, the higher its cost, respectively.

Types of parquet board

There are several types of parquet and what parquet board to choose, solve you. Now you can meet such types of parquet board:

- The massive parquet board - is one of the most expensive types of parquet, as it is made of elite wood species. It is highlighted by high quality and durability, modern design, a variety of color scheme, which gives great opportunities in the design of any interior.

- Parquet - the most common type of parquet board, has a sufficiently long service life and, if necessary, it may be subject to restoration. From the piece parquet make a beautiful artistic parquet with many different drawings and patterns. Such a floor covering looks very beautiful in living rooms or bedrooms.

- Laminated parquet is an artificial substitute for a parquet board and has the lowest cost among all the current types of parquet. It stands out with a simple and high laying speed, as well as good wear resistance, so most often such a parquet board is used for hallways.

Methods of laying parquet

Laying the parquet board, whose video can be viewed before starting work,

can be made in several ways. Each of them has its pros and cons. There are such ways to lay a parquet board:

- Floating - suitable for small rooms and assumes the connection of a parquet board using a spike-groove technology. Such works are performed on the final screed and require laying of the heat insulating layer;

- On the self-tapping screw - a simple and fast way, since it does not require a floor screed. The surface is leveled with plywood or OSP;

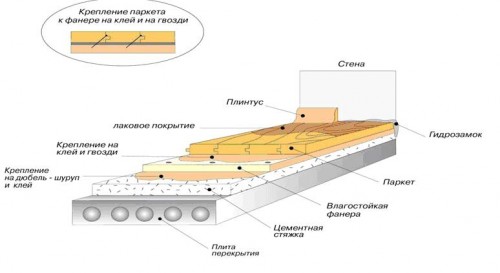

- on glue or bitumen mastic - involves the use of plywood in the form of a base, for which parquet boards are mounted using two-component glue or mastic. This method is characterized by increased strength and reliability of the coating, as well as high noise insulation;

- SAFE-LOCK lock mode - a quick and reliable method of laying parquet. He reminds something floating, but unlike the latter does not require the use of glue.

Laying parquet

Before starting the flooring of the parquet, it is necessary in advance in unpacked form to withstand in the acclimatization room.

So, determined with the material and method of its laying, you can proceed directly to the work itself. Consider laying parquet on glue. To begin with, we clear the room from furniture, outsiders and debris, as well as dismantle old plinths and flooring, leaving a bare concrete floor. Then we will deal with the alignment of the concrete base, for which we will carry a tie of the floor.

The code it will dry completely, and this is about two days, you can proceed to applying the primer material.

Pre-open the plywood sheet for four squares. They will serve as a substrate. They are attached to the base with the help of bitumen mastic or two-component glue. At the end of the process of flooring, plywood will carry out its grinding with a grinding machine.

After that, go to the laying of a parquet board.

It is worth noting that they can be mounted in different directions, laying out all sorts of drawings, for example, in the form of direct or unfolded squares, carpet, straight lines, a Christmas tree, with a frieze or without it. We begin laying from the wall, happing every plank glue and applying to the bottom, in addition they are also fixed with nails.

Ready only laid parquet flooring are grinding, and then covered with varnish, which is applied in several layers using a roller or spatula. Each layer must dry well and only after that the plinth is mounted.