Pipes CPVH: characteristics, application Plumbing

Today on the market there is a unique material for the construction of pipelines - these are pipes from chlorinated polyvinyl chloride (CPVH). For the first time they appeared in the United States about 50 years ago. This became possible due to the development of aerospace technologies. Over time, they began to be used for laying cold and hot water networks in apartments and private houses. In Russia, this product first began to be made since 2008. On the characteristics and advantages of the use of pipes CPVH further.

Content

Advantages

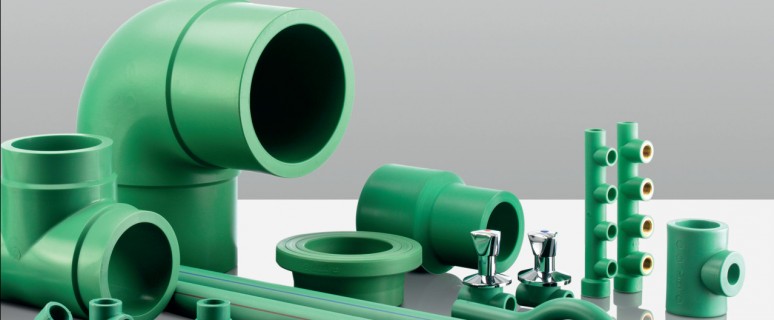

Pipes and fittings of CPVH became popular due to the fact that they have many advantages:

- So, one of them is that they can work at a temperature of up to 95 degrees. Conventional PVC pipes are used only if this indicator is no more than 55 degrees.

- Ease of installation. CPVH pipes were initially developed in order for anyone to establish them independently. After all, their details are very easily connected to each other.

- Aesthetic appearance. If the pipes are correct correctly, they even look quite attractive even without staining.

- These pipes differ from other quality and durability. Due to this, the plumbing built of them is quite reliable and wear-resistant.

- They are resistant to ultraviolet rays. Thanks to this, they can be laid over the walls open. It is also allowed to hide into channels or under the plaster.

- Efficiency. When installing pipes CPVH do not need to use hot welding and other expensive tools. Elements are connected to each other by cold welding, as a solvent for which glue is used. As a result, after gluing, the finished system is a monolithic structure. If the installation of a complex design is required, then it is better to charge it to those skilled in the art.

- You can buy CPVH pipes in almost any construction store.

- Another advantage is that they are, due to their composition, do not produce harmful bacteria. For example, with a plumbing of such pipes, there is practically no problem in which water has an unpleasant smell due to the fact that it contains a precipitate.

- Pipes CPVH, reviews about which only positive, have good resistance to burning. For their ignition, it is necessary that the temperature of the external environment reaches 433 degrees. Ignition is possible only when the source of fire is located nearby. Moreover, if the pipe is removed from the firefight, it quickly fades.

Pipes CPVH: Specifications

Consider the main characteristics of PPVH pipes:

- The modulus of elasticity is 2400 MPa.

- Density - 1.57 g / cm3.

- Available thermal conductivity - 0.14 W / (M · K).

- The yield strength during tension is about 55 MPa.

- The thermal conductivity coefficient is 0.137 W / m ° K.

- The calculated strength of the material is 10 MPa.

- The linear extension coefficient is 0.65 by 10-4 mm / ° C. Its value is almost twice lower than that of polypropylene and cross-linked polyethylene.

- The life of the material is an average of 50 years.

- Pipes CPVH: price average -90-200 rubles per 1 meter.

The specified thermal conductivity coefficient gives a guarantee that heat loss in pipelines will be less. In addition, it means that condensate will not be formed on the surface of such structures.

This technology is particularly relevant now when the volume of monolithic housekeeping is large enough. In addition, it is allowed to use emptiness and cavities in brick and concrete elements for laying pipes from CPVH.

Application

Pipes from this material today are widely used worldwide. Often they are used to build a heating and water supply system. Designs from CPVH are used not only in type mass construction, but also when the unique objects are built according to individual drawings.

These pipes also have high resistance to the negative effects of chemicals. They can transport not only water, but also some acids. For example, such as sulfur, nitric, phosphoric and salt. It is allowed to transport oil, soap, mercury, oil, fat, milk, beer, wines. The most important thing for food is that when moving through such pipes, they do not change the taste, color and smell. At the same time, if you lay the CPVH design underground, they will not be exposed to harmful trace elements that can be in the soil.

Installation of pipes from CPVH can be carried out without additional protection against sunlight. The fact is that the composition of this material is titanium dioxide, which is an additive, widely used to protect against ultraviolet. Due to this, the service life of the designs of CPVH does not become less when installing under the open solar rays. This is very advantageous from other types of polymer pipes.

Fire safety

Plastic, from which pipes are made, has one essential disadvantage - it is strongly susceptible to burning. Moreover, during fire, drops are often formed, which make this material even more dangerous. Pipes from CPVH are deprived of this shortage, they have excellent fire prevention properties. After all, this material is 30% consisting of carbohydrate raw materials and by 70% of the inorganic (table salt). Due to this, PVCV acquires the following properties:

- Low smoke formation.

- Minimum combustion toxicity.

- The index of the oxygen index is 60. It reflects the oxygen content required to heat the material. The atmosphere has about 21 percent of oxygen. Considering the value of the coefficient for CPVH pipes, their fire may occur only when an additional supply of 39% oxygen is carried out. Therefore, this material can be attributed to self-refining.

FEATURES OF MONTAGE

Pipes from CPVH are connected to each other in several ways:

- By gluing.

- Threaded connection.

- Fixation on free flanges.

Method 1.

The adhesive compound method is based on a chemical diffusion at which the surface layer of the material penetrates into the fitting design, resulting in a monolithic compound. This method has several important advantages, namely:

- Low labor costs.

- Simplicity and ease of installation, which allows you to mount pipes even in hard-to-reach places.

- Low cost.

- The speed of work.

- No need to use welding equipment.

- No costs for electricity.

- When mounting pipes, the axis of each of them is strictly on the same line. Due to which you can create smooth and symmetrical structures.

- When connecting pipes with each other, there are no influxs that are characteristic of confusing by conventional welding. Such defects are harmful to that reduce the hydraulic characteristics of the system.

According to the specified properties, it can be safely said that the adhesive compound of the material has good economic feasibility. This in the aggregate makes the system from the HPVH pipes very favorable and reliable.

Procedure for work:

- Measure and smoothly cut the material. To do this, you will need a metal hacksaw.

- Remove the chamfer with an angle of 15 degrees at the end of the pipe.

- All structural elements are cleaned of dirt, chips and dust.

- The glue to the end of the pipe and the fitting is applied.

- Insert the pipe into the socket. Machine and fix fitting.

Method 2.

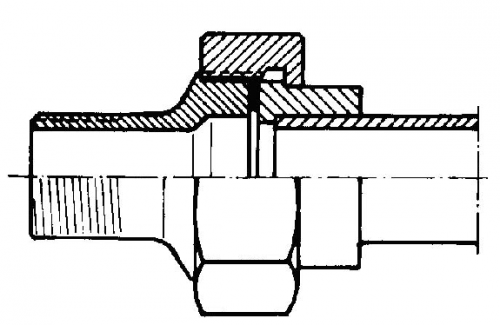

The connection of the HPVH pipes on this method is performed using a plug-in clutch with pipe threads or combined fittings with mortgage metal elements. When fixing the material, this method needs to correctly calculate the applied force. So, mortgage elements should not be turned in the body of plastic fitting. Seals in this case are fluoroplastic tape or fibrous material (Len Santechnic).

Method 3.

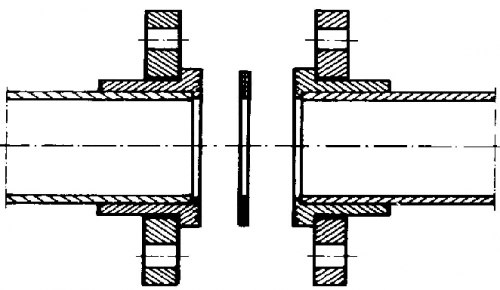

The compound according to this method is performed using special sleeves with boot and socket. On them, freely rotating flanges are installed under the adhesive compound.

It is known that polyvinyl chloride has a rather low thermal expansion coefficient. Despite this, you need to consider a certain probability of deformation of the design when designing and installing the water pipe system. Therefore, to eliminate the internal voltage, you can use stationary or moving holders when installing.