Chernovaya floor in the house. Sounds of laying Floors

The draft floor, along with the walls and the roof of the house, is the basis of the whole structure. The absence of a screens and any deformations of the floor covering over time - the result of a qualitative and reliable device of the draft floor in the house. The main thing is to correctly choose the method of its structure, based on the type of structure and the conditions of future operation.

Content

Structure of roughing

Despite the diversity of interpretations of this concept, the draft floor is the basis for laying the finishing flooring.

Depending on the purpose of the house, the draft floor is:

- single-layer, consisting of aging flooring or concrete base, on top of which a plywood coating is placed in the form of plywood. Such a structure of the floor is used in the buildings of periodic accommodation in the warm season of the type of country houses, or in combination with a well insulated basement;

- multilayer characterized by a single-layer coating with the creation of additional layers of hydro and thermal insulation.

Thus, only a multilayer structure is used to arrange a draft floor in a private house, while a single-layer option is also suitable in multi-storey buildings.

Black Coating Mounting Methods

Regardless of the number of layers, the creation of the base of the draft floor occurs in one of the following ways:

- dry. Work on the floor laying is based on the use of wooden components (timber, beams, boards, etc.). In this case, the auxiliary elements in the form of pillars and other elements can be created with a concrete solution or brick;

- wet. Laying the draft floor occurs through concreting pre-prepared base.

Creating a rough coating with a dry or wet way can be performed in different ways, therefore, before you dwell on one or another option, you must get acquainted with the subtleties of laying each of them.

Installation of black coating with a dry method

Currently, the creation of cauldron for finishing sex is carried out in several ways that differ in both the technology and the installation rate.

On the beams overlap

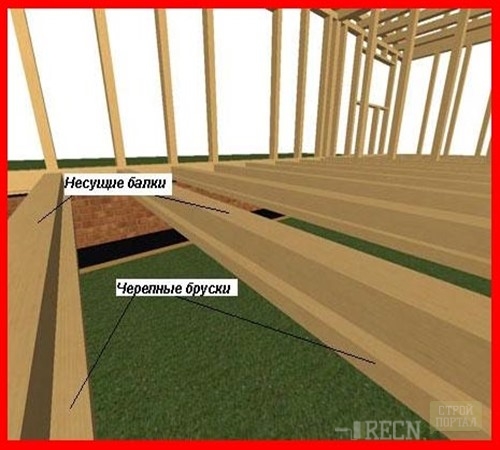

Overlapping beams are performed as the main element of the design of the draft floor, which are completely or partially cut into the walls of the structure.

Black floor laying technology is as follows:

- The side of the beams intended for laying a clean floor, we make as smooth as possible to avoid unwanted distortions.

- At the top of the beams, perpendicular to their location, we make grooves for laying lag in 60-100 cm increments.

- To the lower part of the lag, on both sides, fasten the cranial bars width 4-5 cm. Instead of bars, you can use boards. In this case, the width of the boards is selected taking into account the width of the lags so that after fixing the edge of the boards protrude beyond the limits of the bar from one and on the other side by 4 cm.

- In the resulting squares lay pre-dried boards.

- Prepared bases cover with vapor barrier material, fixing it above the level of finished gender. The docking of the seams is carried out by a mustache with the subsequent sinking scotch.

- Between lags, we place the insulation. If the height allows, then you can lay 2 layers of thermal insulation. At the same time, a distance of 2 cm remained between the insulation and the upper edge of the lag, which plays the role of ventilation. If the insulation is at one level with the top of the lags, then the ventilation gap is created due to the fixation to the lags of counterrevasses with a thickness of 1.5-2 cm.

- A layer of waterproofing is stacked from above, which is attached similarly to vaporizolation.

- Over the waterproofing, we place the clean floor of plywood, fiberboard or other materials.

This technology allows you to securely insulate the roughing floor from the soil, increasing its operational period. In addition, the flooring device on the beams gives the additional strength of the entire structure, being an integral element of the house frame.

However, the use of a floor system on beams is no good sound insulation, since any floor oscillations are transmitted by means of beams on the walls.

Some other variant of styling video video:

Based on

In most cases, the laying of the draft floor in the brick house is made on the base of the tape fundament or scold. In addition, the flooring device based on the base is accompanied by the construction of support pillars that increase the strength of the structure.

The procedure for performing work comes down to the following:

1. Select the method of laying the lag. The placement of the lag on the foundation base is preceded by the manufacture of lower strapping from a small thickness of boards or a bar. For the subsequent attachment of the lag in the strapping, it is necessary to make grooves, the depth of which corresponds to the width of the bar. When laying the lag on the woodlock, it is necessary to pre-cover it with its rubberoid in 2 layers.

2. Place the locations of the lag. The accommodation step depends on the type and width of the heat-insulating material, as well as from the thickness of the boards that will be laid between fixed lags. Based on this, the thicker board, the less the laying step will be. The markup of the future location of the lag is made by a pencil on the strapping or chalk along the wrapped waterproofing. At the marks produced, between the opposite walls, we stretch the line, denoting the axis of the placement of the lag.

3. We look at the location of the supports. First, align the ground inside the room, after which we proceed to the markup. The first pillar, as the next, is removed from the foundation by no more than 1 m. In this case, the lag axis should pass through the center of the future support. To do this, with a plumb or roulette, if the distance from the soil to the fishing line is no more than 0.5 m, mark on the ground line, parallel to the axis of future lags. From the line scheduled on the ground, as well as along the line from the center of the support, we mark on both sides of 20 cm and set the pegs. Thus, the dimensions of one reference pillar will be 40x40 cm.

4. We arrange the foundation under the support. In the places marked under the columns, we take out the ground to the depth of 35-40 cm. Upon completion of this operation, it is pretty tamping the ground at the bottom of each pit. We make a drainage of the foundation, falling asleep to the pit first in large gravel, and then sand. In this case, the thickness of the layer of a separate subfocation is 10 cm. Each layer is thoroughly tamped. Construct formwork, protruding at 5-10 cm above the level of soil. Inside the formwork, we establish a reinforced frame, having it slightly below the center, and fill with a concrete mixture. After a week, formwork can be removed.

If the support is completely cast from concrete, the formwork is based on a height equal to the distance from the soil to the location of the lag.

5. We will be erected by a brick support. On the hardened foundation lay 2 layers of rubberoid, we apply a cement solution and put bricks in 2 rows, continuing the laying to the top of the support. However, the top row of bricks, we have so that in relation to lags they lay perpendicularly.

During the construction of the supports, it is necessary to control the top of the pillar to be located at one level with the base under the laying of the lag.

6. We prepare the supports to lay the lag. The top of the columns are covering the rubberoid, on top of which the sealing gaskets from any girlfriend are found. The use of pads increases the soundproofing characteristics of the draft floor.

7. Install lags. First, we place the lags by the walls, following this, so that the distance of the supports of these lag over the basement or painter is at least 10 cm. If this value is smaller, then in the walls of the overlap you have to make grooves on the missing length. We check the horizontal of laying individual lags and their placement relative to each other by means of a hydraulic level. If the level is observed, then fix the bar with a metal corner to a wooden base with self-draws, and to brick, concrete - a dowel-nail or anchors. We check again the level of fixed lags, after which we stretch the line between them, which will serve as a certain level of horizontal for laying the rest of the lag.

There should be a gap of 2 cm between the lags and the wall, which compensates for the negative impact of various factors.

8. Krepim cranial bars to the bottom of the lag. Instead of bars, you can use boards whose width exceeds a lag width by 8 cm.

9. In the finished crate, flooring board.

10 Laying of the subsequent layers is carried out by analogy of the first option.

The advantages of this method consist in a small load on the foundation caused by the relative ease of construction, as well as the absence of high humidity, due to which other finishing works are carried out in normal mode. The only minus - such a design can not be built and operated under conditions of a high level of constant humidity, otherwise the durability of the structure will be very conditional.

Despite the complexity and duration of the work, the black floor in the frame house is produced in a similar way.

On the slabs of the overlap

If the basement or inter-storey overlap is made using reinforced concrete slabs, the construction of roughing floor is greatly alleviated. In addition, the presence of the ceiling slabs allows you to use sufficiently new methods of the black coating device, among which the national trades were obtained on adjustable lags.

When building such a system of flooring, the work is carried out as follows:

- in a concrete base, after 50-60 cm, plunge special pins, the diameter of which is 8-10 mm;

- in bars through a distance equal to the pitch step, drill through holes;

- lags begin to fix on pins placed in opposite sides of the room;

- horizontal Lag corrected by rotating a special key bolts located on each pin;

- lagi we combine a fishing line, which will serve as a guide to install the remaining bars;

- after installing all the beams and checking their horizontal, we cut off the baccake protruding tops of the pins;

- boards or Phaneru put on lags with an indentation from the walls of 2 cm. Plywood plywood is carried out on the lags. At the same time, more than 3 angles should not be converged at one point;

- the fastening of plywood to the bruster is carried out by self-drawing.

The gaps formed in the process of laying the draft coating between the walls and the boarding line are overlapped with the insulation.

Thanks to this method, a high vehicle mounting speed is achieved, good ventilation is ensured due to the free space between the concrete base and lags, and there is also no creaking of the flooring. However, the cost of such a design will be pleased with everyone.

Thus, when creating a draft floor, it is worth considering the advantages and disadvantages inherent in one or another method of laying.

Installation of rough floor with wet method

Laying the draft floor in a wooden house through a concrete screed is possible in 2 ways.

On soil

The process of the construction of roughing floor on the soil is as follows:

- align the base inside the foundation perimeter followed by the seal;

- i fall asleep with small rubble to a height of 10-20 cm, we will be tamped;

- on top of the rubble, we lay 10-15 cm of sand, moisturize and tamper it;

- we put a vapor insulation layer using polymer-bitumen membranes or PVC, so that the edges of the membranes enter the wall to the entire height of the future;

- we place thermal insulation in the form of minvati, crumples and other materials;

- wealing the polyethylene film, creating a waterproofing layer;

- put the reinforcement grid;

- pour the layers with a concrete solution to a height of 5-10 cm;

- cover the polyethylene film for uniform rejection. For a month, while the concrete screed is gaining strength, it must be made with water to avoid cracking of concrete;

- in a month, align the floor by self-leveling mixture, after the drying of which can be started to lay the fixed coating.

The use of this method is possible if the house is located on stable soil with low groundwater levels. You should not use such laying in summer houses, which in the winter it is not heated, resulting in the soil freezing and the concrete screed begins to gradually collapse.

On the slab overlap

The technology of performing work when the flooring device on the overlap is somewhat different from the creation of a screed on the ground and is performed in the following order:

- align the base of the plate by means of a concrete screed if there are significant differences;

- after rejection, the scrolls arrange a vapor insulation layer;

- the next layer is the insulation, on top of which the polyethylene film is placed;

- pour the layers with a concrete solution by 3-5 cm;

- a month later, you can lay any floor covering.

Concrete floors in the house, black especially, are characterized by high strength and durability, since they are protected from damage to the finishing flooring. At the same time, the flooring device with the use of a concrete screed requires pre-conducting appropriate calculations on the carrying capacity of the structure, since concrete is a rather heavy material.

Thus, the draft floor is a significant moment in the construction of the house or in the process of repair, on the quality of which the duration of the operational period is dependent, the reduction of thermal losses through the basement and many other factors.