How to handle the plywood Building materials

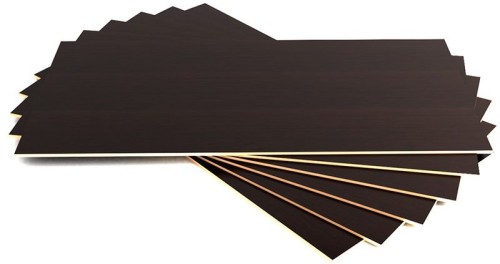

Plywood - one of the most popular materials in the construction and finishing works. It is made from wood by gluing together veneer layers so that each successive layer is applied perpendicular to the previous fibers. Professionals appreciate the versatility of plywood to use, and affordability in price. The main drawback - the material is afraid of water. If improperly treated plywood layers damp decay, warp and, subsequently, the material is converted into dust. How to handle the plywood to protect it from rapid wear - a very pertinent question, if you have decided to carry out all construction work. There are several ways and means to extend the life of the material about which you and learn from this article.

Content

processing Methods

To protect the plywood against the rapid deterioration, it is necessary to protect against the adverse effects of external aggressive environment. For this case, the materials were employed, which can ensure waterproofing and protect it from wear during temperature changes.

How to handle the plywood:

- Fiberglass.

- Varnish.

- Linseed oil.

- Paint.

Separate nuance - most susceptible to the harmful effects of moisture veneer sheet ends. They require very careful handling and additional insulation. To ensure the protection of such places, perform such work:

- Caulking.

- Casting edges with metal or plastic edge.

- Processing deep penetrating primers.

- The use of dense paints.

Important! Before you choose the option of protective processing of plywood that suits you, familiarize yourself with the pluses and minuses of each material, its cost and find out how easy the application technology is. Only after that, take the final decision.

Fiberglass salary

Such waterproofing of plywood significantly increases the service life of the material. It is performed by applying special fiberglass to the surface. If such a material is unavailable, you can use an ordinary gauze. It is glued with any of these materials with varnish. The main condition when choosing such a solution - it should not be polyester and epoxy components.

Conduct work with fiberglass or gauze in such a sequence:

- Cover plywood sheet with varnish.

- Give lacques to absorb within 3 hours.

- Apply marla or fiberglass on the surface.

- Treat leaf ends with varnish.

- Leave dried for a few days.

- When you make sure that the lacquer is dry - re-apply varnish on the entire surface of plywood.

- Consider a few more days.

Impregnation of Olifoy

The most popular way of waterproofing plywood is the processing of its oliff. It is available at a price, sold in any construction store and significantly increases the moisture resistance of the material. In order for the work to be more productive, Faneur need to soak hot oil.

Work consists of such steps:

- Heat the olive to 60 degrees in the water bath.

- With the help of a tassel, apply a solution on a plywood sheet, paying special attention to the edges and end.

- Take the construction hairdryer and perform forced surface drying. If you do not have a hair dryer - ignore the phaneer iron, heated to 200 degrees.

- Make sure the olif is completely dried, and apply another layer of substance.

- Apply each layer until the olifer stops absorbed.

Important! After all the manipulations carried out, the plywood sheet is ready for painting and installation. For the convenience and quality of application, handle the phaneer, which is in a horizontal position.

Staining plywood

When the question arises than to treat the Phaneur from moisture, experts advise to cover it with varnish or paint. These materials unambiguously extend the life of the plywood sheet. For quality work, using paint, you will need:

- sandpaper;

- putty;

- primer for plywood;

- tassel, roller or sprayer;

- putty knife;

- paint for plywood.

Selection of paint

In order to maximize the service life of the coating from this material, when choosing a solution for processing, consider the following recommendations:

- The paint is perfectly coping with water-repellent function and engraves the appearance of plywood.

- If you intend to install plywood sheets in a residential room, choose paint for them on a water basis. It does not have a pronounced unpleasant odor, dries quickly and easily applied.

- If you work in the open space, it is better for this purpose enameled paint for wood. Any of them you can purchase both in the finished form and in concentrated, which are designed for self-taking.

Staining technology - Method 1

Full-fledged painting technology consists in several stages:

- Using the emery paper, polish the phaneer before smoothness.

- Apply acrylic primer with roller or tassel.

- Let me dry for several hours.

- Prindline surface, eliminating all microcracks.

- Leave the sheet to completely dry the putty.

- Collect, eliminating all the irregularities caused by putty, to even base.

- Again, spend primer work.

- Make the technical pause until the solution is completely drying.

- Prepare paint if you have been on your own.

- Paint a plywood sheet.

Important! Grinding is carried out with coarse sandpaper - it allows you to eliminate all irregularities on the surface. To give the perfect smoothness, grinding is made fine-grained emery paper along the structure of plywood fibers.

Primer and putty perform the following functions:

- elimination of microcracks;

- qualitative leveling of the base;

- protection of wood structure from mechanical damage.

Staining technology - Method 2

Another way to protect plywood from moisture implies the use of nitrocracy together with the cloth. Usually apply a bump or mitkalic tissue. Plywood treatment with these materials is carried out like this:

- Apply Olifai layer on a plywood sheet.

- Dry for a few hours.

- Treat liquid paint that will carry the function of the primer layer.

- Again dry.

- Generously cover the phaneer with a layer of thick paint or nitro-spacure, preliminarily explores its solvent.

- Prepare fabric and spread it all over the surface of the plate. Lightly press.

- Soak solvent for nitrobras. It is convenient to do it with a tassel.

- Wait until it dry, and cover the entire surface of the liquid nitrocracy.

Important! Experts advise not to abuse the finish layer, since a large number of paint in the completion of finishing works make coverage less durable. This technology is used most often during self-building boats.

Additional recommendations

A few more features that need to be taken into account when staining plywood:

- The plywood sheets that were in the cheese wet room, before processing it is necessary to dry high quality.

- If you plan to install Phaneur on an open space or in places with high dampness, then color a sheet on both sides and in several layers. Especially carefully handle the edges.

- Staining is not suitable for plywood, which is mounted on the floor. From constant walking along the painted surface of such a paint coating will be peeling and disappeared. In order to decide what to process Phanelo on the floor, consult with specialists in building stores.

- If you are making paint using a sprayer, you will achieve a more uniform color distribution. In hard-to-reach places, use a brush.

- If you decide to paint the Phaneur in different colors, limit the working area with painting scotch.

Video

If you are wondering how quickly paint the plywood attached to the video exactly for you.

Plywood varnishing

Varnish for plywood is also an excellent defender from moisture and dampness. Types of varnishes are designed to work with such plates:

- nitrocellulosic;

- alcohol;

- oil;

- polyester;

- urea formaldehyde;

- polyurethane.

Pluncher selection

Considering such a variety of species and also manufacturers, so as not to be confused and quickly decide on the option you need, take into account such factors:

- The most sought-after plywood from all during processing are nitroleki. They dry quickly, possess the necessary qualities of hardness, moisture resistance and elasticity.

- The most unpopular - alcohol formulations.

- Every year, polyurethane varnishes are increasingly used. This is due to resistance to the effects of atmospheric phenomena, wear resistance and durability.

Plywood varnishing instructions

- Carefully polish the surface of fine-grained emery paper.

- Clean the recycling waste.

- Process the phaneer of the primer and dry.

- Apply the first layer of varnish with long strokes, distributing it throughout the surface. Do it with a brush, roller or special spatula for varnish.

- Wait for a complete drying of the substance.

- Repeat varnish.

Important! Experts claim that the larger layers of varnish you will apply, the longestness and more beautiful will be the coating. Before each the next treatment with varnish layers thoroughly dry. At the end of the processing, apply Olif or Vegetable Oil to the surface of plywood, it will give the tree a more rich and deep shade.

Additional ways to process plywood and their features

In order for all the work on the cutting and preparation of plywood to finishing work, you have given much easier, read the recommendations of professional builders:

- Align the edges of the plywood sheet. If you want to avoid splitting the material, handle the wood from the corners to the center of the sheet.

- Grinding. Use for this type of work coarse emery paper from №80 and higher. Work perpendicular to the structure of plywood fibers. For grinding under painting or varnishing, use fine-grained paper by working in the longitudinal direction.

- Drilling. To work with a plywood sheet, give preference to the acute drill with the front cutter. Drill with the face of the material using a lining to prevent the formation of chipping.

- Sawing. For the front of the sheet, use a ribbon saw. For the wrong disc.

- Primer. This type of processing should be carried out at mandatory. It will provide an additional protection against adverse external factors. For a better result, infuse Phaneur on both sides.

Extending the service life of plywood structures

A few more tips to increase the life of plywood will help you to save in the future for unforeseen repair:

- If the plywood sheet is installed outside the building, try to place it under the canopy.

- Cover the structural materials made from plywood by other finishing materials, especially if it is located on the street.

- Place the vertical surfaces of the sheets too vertically.

- The most vulnerable plates on the plywood are fastening zones. Therefore, all areas next to self-drawing and nails should be especially carefully processed.

- If you find a plurality of small cracks on the surface of the plywood coating, it means that it requires urgent measures. You should not paint crack without prior processing. At first, with the help of sandpaper, remove all peeling elements, and then restore the protective coating with varnish or paint.

Conclusion

Plywood is a wood material that is exposed to temperatures, humidity and pressure. With proper care and when providing adequate waterproofing, this material is capable of listening to you for a long time and efficiently. Properly applied plywood protection technologies will allow you to achieve the desired stove strength and do not worry about the need for its replacement in the near future.