Wooden Power Staircase: Manufacturing Instructions Ladder

The staircase of the palter wooden is necessary in the farm, where there is no other opportunity to climb the roof for cleaning it from snow or last year's leaves. With this device, you can cut extra branches of trees or collect fruits. Modern staircase Fiberglass Pottal standing is expensive, so we'll figure it out how to make a wooden dormital staircase.

Content

Types of the designs of the inlet stairs

Depending on the features of use and storage, the insertion stairs come in the following designs.

- Stairs Power sliding: They are equipped with grooves-guides in the assets for which other sections are moved. The advantage of the design is the compactness in the folded state and the ability to set the angle of inclination of a smaller than that of the stairs of another type.

- Foldable: most often used as a staircase for lifting in a attic or a mansard level. Consists of several sections connected to each other by hinges. Folded is attached to the ceiling.

- Pottal - Inspection design without the possibility of transformation. It is installed at an angle of 60-75 degrees on the floor below and rests on the vertical surface of the upper parts of the taper. The staircase is made easier for the staircase with their own hands than other types of stairs.

Requirements for Potter Stairs

Stairs to look beautiful, and most importantly - be safe, you must observe a number of rules for its production. These rules are specified in the regulations, developed by experts on the basis of calculations and tests (GOST 26887-86, GOST 24258-88, POT RM-012-2000, SP 12-135-2003). The first document contains the basic information, such as:

- maximum length ladder must not exceed 5 m;

- the bottom of the ladder is to be in focus as rubber overshoes or steel pin;

- at the top of the hooks must be installed to secure the ladder to a vertical surface.

If the ladder is operated on loose surface (dug soil, sand, etc.) should be reinforced at its lower ends of the support laths with steel pins. They will not let slip design load. On a smooth and hard surface needed rubber overshoes (shoes). To the ladder was universal, these pads should be done with removable.

Among other requirements set out in the regulations, the following must be highlighted:

- step steps chosen in the range 300-340 mm;

- stage element should be in the cross section is not less than 20 × 40 mm;

- for mounting the steps of the supports (withs) in the past doing a groove;

- bowstring are fastened together by tightening the bolts in the region of the upper and lower stages, as well as every 2 m over the entire length;

- the presence of transverse cracks timber is not permitted, the longitudinal should not exceed 150 mm in length and 5 mm in depth.

Tests of a ladder in accordance with the requirements of regulatory documents produced annually. To this end, each stage of the angled 60-75 degrees loaded with 120 kg load. By the side edge of the string is attached plaque with the date of the next test.

The materials used for the manufacture of stairs

By the choice of wood should be treated carefully. Discarded bars with signs of decay, transverse cracks, large knots, kososloyami and affected insects. The wood must be well dried and flat, preferably softwood. Minimum section bars to be selected as follows:

- 40 × 50 mm - for withs stair height of 3 m;

- 40 × 80 mm - for withs stair height of more than 3 m;

- 35 × 40 mm - for manufacturing stages.

All items ladders made of wood should be treated with antiseptic.

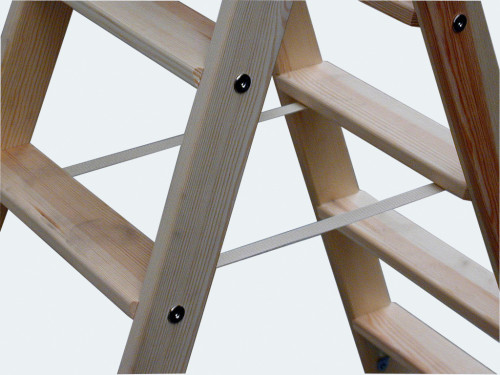

How to connect the ladder elements

There are several ways of constructional elements ladder compound.

- Surface method involves mounting boards that perform the function of steps, to the supporting joists by means of screws or nails. This is the most simple method, the disadvantage of which are uncomfortable for the foot step and unreliability structure.

- With tie-steps the boards fastened to the bowstring in a half-tree in areas where specially made for this sample in the timber.

- Finger-jointed: on the edges of the boards are cut projections and bowstrings - the slots for them. The compound may be formed at an angle. This mount has the greatest reliability.

ladder manufacturing technology

Ladder with their hands made by the following set of tools and accessories:

- circular Saw;

- chisel;

- hammer;

- elektrorubanok;

- sander;

- electric drill with a set of drill bits;

- screwdriver curly;

- roulette;

- carpenter's pencil;

- workbench.

Step by step instructions for the manufacture of ladder.

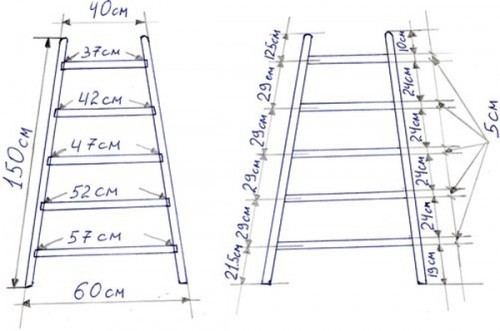

- To work needed drawing. It can be run independently or borrow one of the sites on the web.

- Bars for withs (uprights) cut to length and one treated with a plane and polished. It is important that their surface was smooth.

- On a flat surface future bowstring stack so that between the upper ends of the bars was 400 mm distance, and between the lower - 600 mm. Details temporarily fixed by nailing boards on both sides.

- Harvested parts for steps, and treated similarly. Their length is initially selected to be equal to the maximum distance between the withs - 600 mm.

- At a distance of 290-340 mm from each other throughout the length of the support bars mark the places for fixing steps.

- Details for steps customize the distance between withs and numbered, marking their positions, and also on the side of the string. The edges of the steps recommended with rounded edges.

- Along the edges of parts for forming stages spikes.

- At appropriate places supporting bars chisel punched slots for attaching steps. The profile and size of the slot should be suited to the size of the stud with a small gap that allows to assemble.

- On the grooves and tenons parts carpenter's glue is applied. Spikes wrapped in one or two layers of gauze (medical bandage can be replaced) and then re-coated with adhesive.

- Details staircases connect starting from its upper edge and tightly fitting to each other.

- Under steps at the top and bottom in the assets drilled holes for tie bolts. Power staircase, the dimensions of which are in length exceed 2 m, should have additional tie bolts.

- Insert tie bolts, they screw the nuts on the edges on the thread, putting wide washers under them.

- The staircase is treated with a paintwork.

- To the bottom of the spike or shoe, to the top - special hooks.

- Tests are performed.

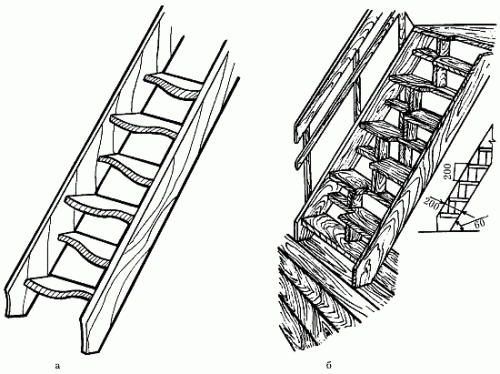

How to make a folding gear staircase

The main advantage of such a design is compact. It can be stored in a small pantry or in the attic. Such a staircase can be used as a stepladder. For its manufacture, in addition to the above list of fixtures and tools, add:

- cord from Capron (2 coils);

- glue universal;

- scotch;

- connecting transforming mechanism (hinge);

- steel bolts with nuts.

We will need a 100 × 20 mm boards (for crossbar) and a 40 × 40 mm ram.

The manufacturing technology is largely similar to those described above, but there are some nuances. The sequence of work is as follows.

- Detail cut from two-sections of two sections of the stairs. The length of the sections should be the same, and the design depends on the capabilities of the hinge. In this regard, the width of the sections can be at the same time the same or staircase can be expanding to the bottom.

- Prepare parts for steps.

- Collect two stairs sections, their surface is grinning, paint covers.

- At the bottom of one of the sections are fixed by shoes, respectively, at the top of the other - the hooks (or shoes, if the staircase is intended to be used as a stepladder).

- Install tie bolts.

- Hinges are attached to both sections with bolts with nuts.

- To limit the transformation sections in position ladders is attached to the side surface thick nylon rope or long hooks, which are made of steel wire with a diameter of 8-10 mm.

- The staircase tests in all its work positions.

Duck Step Ladder

This design is convenient if the staircase is operated as stationary. In this case, the steps are made of boards. The width of the steps is different: one part is made wide (about 300 mm), another - narrow (200 mm). Wide parts alternate with narrow along the entire length of the stairs. The crossbar is fixed with three spikes, since the width of the steps is greater than in the stairs of other structures.

In conclusion we suggest to familiarize with the video tutorials on making a wooden ladder.