Repair of the old parquet do it yourself. What to close the gaps in the floor Floors

Parquet floor - excellent materials for floor covering. The service life of more than 50 years, but under the influence of time the structure of the floors changes: the appearance disappears, noticeable cracks appear, the planks pee out, creap appears. There is a need to fully replace the floor or partial repair. Repair of a parquet floor with your own hands is a real opportunity to save money and benefit for yourself.

Content

Repair of a piece parquet. Preliminary work. Building materials and equipment for repair

Preliminary works include:

- Full removal of furniture, things from the room. Repair and restoration of parquet will lead to a large accumulation of dust

- Removing plinths. Necessary for high-quality parquet processing

- Removal of an old coating from doorways

- Dust cleaning

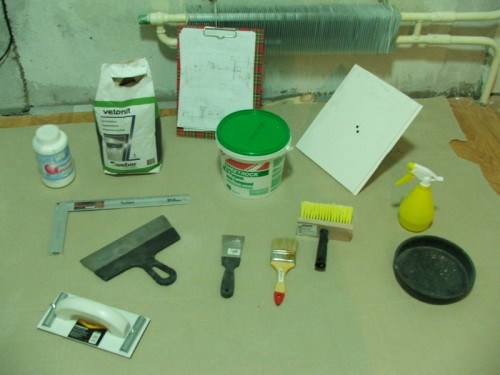

Building materials and equipment for repair:

- Long pile brush, for floor painting.

- Billets for replacement of old.

- Varnish, which has good wear resistance.

- Glue for gluing damaged slats.

- Lubrication or putty, to eliminate small slots.

- Putty knife.

- Dyes for the floor.

- Emery paper with conventional and fine-grained skin for manual grout.

- Manual squabble.

- Plane.

- Sander. Normal and hand delta machine.

- Circular sandpaper for machines of different grainability from 24 - for coarse processing and 80 - for thin grinding.

Stages of repair of old parquet

The first stage. Repair and Cyclical Parquet

Parquet's cycle is necessary for removing the upper, burglar layer of varnish or mastic. You can use a manual citner that is purchased at any store. The choice of manual cycles is large enough, it is best to use a cincon with a short handle. When using a cycle with a short handle, a lot of time and strength will be spent, but the result of processing will be good.

The plot that is processed must be sprinkled with water and start a cyclusion from the middle of the room to the wall, then in reverse order until the end of another wall. So statenly, the strip behind the strip is the whole parquet. In this way, the cyclove is carried out more than 3 times.

You can rent a grinding machine. Purchase circular emery paper of different grainability for it. Grinding machine is useful at all stages of repair of parquet.

At the first stage, they use rough processing of emery paper grainability 24. After carrying out the grinding, all flares are eliminated: replacing damaged slats, eliminating the slots.

Stage second. Replacing damaged planks

Damaged strips are extracted on one, since when removing immediately a pair of pieces, you can damage the whole block, which is very tightly bonded. The floor under which there was an old bar thoroughly cleaned from dust and dirt. The new plank is aligned and cut over the hole, then mounted with glue for parquet. Then the load is installed on it and in this position remains for a while.

Also, a new bar can be attached with a neighboring bar with thin nails, which are driven at an angle, but in this case it is necessary to process the replacement sections with a plane.

Only damaged parquet areas are often visible, so it should be hosted each bar to identify emptiness.

Repair of a discrepanged parquet occurs by analogy with a damaged parquet. One feature is that it is not necessary to replace the discharge bar for a new one. It is enough to remove it, dry and, after cleaning the surface, glue the glue back.

The packer has a multilayer design, consists of two layers. The bottom layer is the main, made of inexpensive wood. The top layer is made of their high-quality tree species. When repairing a shield parquet, it is enough to replace only the top layer. For this, a sharp knife is cut out some of the bar and the new is fixed with glue.

Stage Third. Elimination of gaps in the floor

Floor surface defects close up varnish, synthetic resins, construction glue. The use of one or another putty depends on the size of the defects.

To begin with, the gap is thoroughly cleaned from dust and dirt using a vacuum cleaner with a thin nozzle.

Little slots of less than 1.5 mm are close to a special lubricant, which can be cooked independently.

Cooking method:

Sawdust or chips, which remained after the first floor cycle mixed with wood lacquer in a 4: 1 ratio. Varnish can be replaced by epoxy resin. The resulting grease will have a soft plasticine consistency.

The resulting sealant is well mixed and applied to the necessary sections. To restore the drawing lines used awl. After drying, the lubricant remains irregularities that are cleaned by the emery paper coarse, and then fine grain.

The slits that are more than 1.5 mm with a putty will be difficult to close, so you can insert the rails from the tree of the desired size or close the lubricant of the paper mass.

Method for preparing paper lubricant:

The usual newspaper paper on thin strips is cut and fastened with warm water. The next day, the cracked paper mass is mixed, the water merges and is strongly pressed.

Then preparing a plotter. Water is boiled in the enameled bucket, flour or starch is added and stirred continuously. The finished holter has a consistency of liquid dough. After a complete cooling, it focuses several times through the gauze. Then the joine glue is added.

Cooked in small portions is mixed with a paper mass. The grease is filled with grease. The advantages of such a lubricant is that it will be very firmly held and will not spilt over the years.

There is also a varied amount of ready-made putty for repair. They have quick-capting properties, combine materials, and most importantly, have a different color gamut.

Stage fourth. Repair and recovery of parquet. Petrol coating

The next stage is a thin grinding of parquet. If you use sandpaper, then less grainy and tissue-based is chosen. Grout is carried out in small areas. Moves are performed circular, mimic the movement of the machine.

When using grinding machine, fine-grained sandpaper is used.

Parquet floor covering lacquer. It is recommended to apply lacquer into several layers, complete drying occurs after two days.

How to wash parquet after repair

The final stage of repair of parquet is cleaning the room. For high-quality and rapid cleaning it is necessary to add a spoonful of vegetable oil in a bucket with warm water. All sections of the floor are thoroughly washed with this solution, then water changes clean and rinse the surface again.