Cork cover for walls with their own hands Walls

Cork - natural, beautiful, warm and eco-friendly material. He found his use as a decorative wall decoration and not in vain, because the traffic jam is simple in installation and has good performance characteristics. About the properties of cork coverage and how to stick it onto the wall with your own hands, we will tell in this article.

Content

Description and characteristics of cork material

To obtain traffic jam, there is no need to chop trees. Cora is removed manually, while noting the date of this procedure. After that, the plant is left alone for 9 years. This means that the mining of the traffic jam does not harm nature and ecology.

The lifespan of cork trees on average is 250 years. It is worth noting that after each removal of the bark, the plant increases an increasingly attractive layer with a beautiful pattern and structure, and each time this layer is valued more and more.

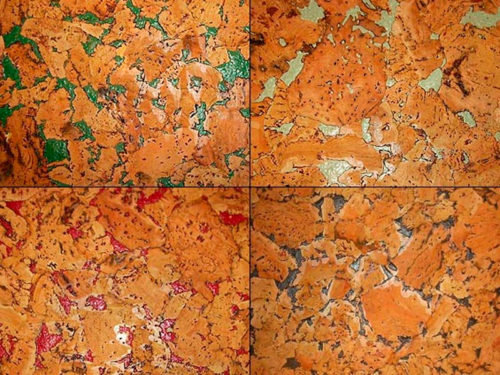

The cork is not taken to paint into other shades, often such a coating has its own natural color. Moreover, the color gamut of the material varies significantly, so everyone can choose the option that is most suitable for the design of the room.

Reviews about cork coverage make it possible to judge that such material has a lot of advantages:

- The plug is completely environmentally friendly, as it is a natural raw material. It does not have a sharp smell, dust not absorbed into it. In addition, the material has antistatic characteristics.

- Easy coverage is another plus. A small weight allows you to easily transport the goods and ensures ease of installation.

- The tube is elastic and elastic. If it is compressed, it quickly acquires the original sizes.

- Despite the seeming porosity of the structure, such a material does not miss moisture. This indicates the hygienicness of the cork cover for the walls, because it does not mold and does not rot.

- Material has good thermal insulation properties due to the same porous structure. It can act as an additional insulation layer.

- The plug does not react with almost any aggressive chemicals. In its composition, it does not contain anything that could cause allergic reactions.

- In addition to the heat-insulating, such material is different and noise absorbing properties.

- Such coating is quite strong, durable, wear-resistant. Does not require complex care.

- In the installation, the cork is very simple. Even one who previously did not have such experience will be able to stick it onto the walls.

Types of cork coatings

Materials made from cork bark are somewhat different in the form of release and technical characteristics. Consider what coating options today can be found on sale:

- Cork slabs - produced from cork granules. The market presents one-layer and two-layer options. Single-layer plates are simply sprinkled and applied on top of a protective wax. Thickness in such a coating of about 2 mm. The two-layer plates consist of a pressed cork covered with a cork veneer. It is applied to special glue with natural composition. Often the main layer of such a material is painted in another shade, so that it is later obtained to get beautiful splashes. Like single-layer, two-layer plates are covered with protective wax. Tiles sizes are as follows: 30x30x0.3 cm or 30x60x0.3 cm. Such material is very durable and can serve from 10 to 30 years.

- Cork rolls are a two-layer material consisting of a pressed plug and veneer applied to it. As part of such a coating there are no synthetic binders, besides, rolls are sold without protective finishes. After their wall mounting, the material is covered with wax or varnish. Rolls from tubes have a thickness of 1.2 to 2 mm. This means that they are more simple in work, it is easier to be flexed and cut, they can be combined with other types of facing materials or, for example, make a panel from cork coverage with their own hands. The service life of the roll plug reaches 20 years.

- Cork wallpapers - the most accessible type of facing. As the basis, in this case, paper is applied to which a layer of varnish and an agglomerated cork veneer is applied. The plug is applied by a thin layer not exceeding 1 mm. Some parts of the paper remain unfilled, and if the base was previously painted into some color, beautiful contrasting splashes are obtained on the finished coating. This material can be combined with other wallpaper, decorative plaster, paint. Corkscale wallpapers are well tolerated shock loads, easily pasted due to low weight and high elasticity, not electrified, do not absorb dust, are considered an antibacterial type of coating. The duration of their service is about 10 years.

- The plug is a mixture of small crumbs of material and a binder on an acrylic basis. Apply a liquid tube on the working surface by spraying. As a rule, such a coating is perfectly engaged with many reasons, it turns out to be durable, moistureproof, long-term in operation. The frozen surface can even be painted in any shade. In turn, the liquid cork is several subspecies: intended for the roof, for the facade and refractory. Such a material allows you to create a homogeneous and completely seamless coating with a thickness of up to 3 mm, which will hide under the slight defects of the base.

- The technical cork does not have the same decorative properties that other cork covers, so it is used not so much for mounting on the wall with their own hands, as as a substrate for various materials. It is produced in the form of plates or rolls with a length of 10 m. The thickness of the technical cork is from 1 to 6 mm. Plates have dimensions of 100x50 cm. Like all other types of plugs, such a material has moisture-repellent, noise absorbing, thermal insulation qualities, is characterized by hygienic, strength, ecology. The plug is resistant to fungi, rodents, insects, microorganisms. Technical traffic jam service life is unlimited.

Installation of cork board on the wall with your own hands

You can separate any premises, including those where the level of humidity is quite high. Installation of such a material something resembles a sticking of wallpaper, however, the procedure is slightly different.

Preparation of materials and tools

Before starting laying the cork cover, you must prepare everything you need, as well as calculate the amount of material. Since in this example we will consider the installation of cork slabs, we take into account their standard sizes, and they are 2 species: 30x30 and 30x60 cm. Calculate the desired number of fragments can be given the area of \u200b\u200ball walls in the room. Thread thickness can be thin or denser, from 2 to 6 mm. With thin, it is easier to operate, but the thickness is distinguished by the best operational characteristics.

Tools will be needed for work:

- building level;

- metal ruler;

- plumb;

- knife;

- mounting scissors;

- toothed spatula;

- glue;

- capacity for glue;

- velor roller for applying glue;

- little roller for seams.

A special contact or acrylic composition can be used as glue. Contact glue is considered better and durable, but also work with it is not as simple as with acrylic. Apply the same composition is necessary not only on the slab itself, but also on the wall. Folding the glue should be evenly over the entire surface, trying not to leave air bubbles. You can not glue the coating immediately, but waiting until glue slips down.

Cork can change its dimensions in small limits under the action of ambient conditions. Therefore, mount the plates on the wall can not immediately after they are unpacking, and waiting for at least 2 days. During this time, the material passes in the room, acclimatizes and will take the necessary dimensions. So you will be sure that the coating is not deformed after installation.

Preparation of the working foundation

Clear cork slabs can be practically anything, whether it is concrete, wood, brickwork or plastered surface. It is desirable that the humidity of the air indoor was within 35-65%. If the room is too dry, correct the situation with the help of the air humidifier. At the venue of the work should also be warm, not colder than 18 ° C.

Walls in front of the sticker plates should be aligned and cleaned of dirt and construction dust. Gaps and holes need to be embedded, protrusions - cut off. The finished reason is desirable to cover the primer corresponding to the composition used by the material. When installing cork slabs, try not to use any gypsum compositions.

On the prepared wall, find the central point, and this will help you with a construction level and plumb. After this point, swipe the horizontal and vertical, also using a plumb and a long metal line. Thus, you will divide the wall to a few identical parts.

Installation of cork coating

- The first tile is installed strictly in the center of the wall at the intersection of the horizontal and vertical axes. Applying a fragment to the workforce, circle it with a pencil or felt-tip pen, and then spread the wall with a thin layer of glue.

- Attach the detail by the bottom edge to the surface and press. Gradually move up, squeezing air bubbles from under cover. Always remember the fragility of the material and try not to take sheets behind the corners, do not bend them too much so as not to break.

- In the same way, glue the sheets throughout the row, using the "in the dispersion" technique, as with a brickwork device. It is necessary in order to make a clear vertical seams on the wall. The second row of coatings mounted with a shift relative to the first row.

- If some fragment lay unevenly, do not be afraid until the glue froze, the material can be carefully moved over the surface. So that at the corners of the tiles did not lag behind, the joints are made specifically designed for this roller.

- Where in the room there are outlets and switches, in the cork cover will have to make cuts. The easiest to use templates for this. They are cut out of cardboard, which is applied to the outlet or to the switch.

- If after drying the glue you noticed that the slots remained between the plates, do not be discouraged. Correct the situation is quite easy. Just cut the narrow strip of the desired length and shape, lubricate the glue and insert into the slot. Slotted glue leave to dry, and then remove the knife.

- Care for traffic is simple. To extend the life of its service, it is necessary to apply protective coating on the material. You can find a special composition with the name "Oil-Wax". By covering a cork with such a means, you will provide additional protection against moisture and dust. In a similar case, the coating can be used even in the kitchen or in the bathroom.

- Instead of wax, you can use a special varnish. As a rule, it is a two-component polyurethane, acrylic or ceramic composition. Note that it is impossible to cover the plug with a varnish for parquet.

- Please note that the plug under the action of solar ultraviolet can burn out and change its shade. To avoid this, take care to the room there are curtains.

Cork cover, photo