What to buy a wood lacquer: water, acrylic, polyurethane, matte, glossy paints and varnishes

Wood products and buildings need protection. For this purpose use impregnation, paints, varnishes. With the help of paint, a tree can be given any color, but the opaque coating will hide the drawing. While lacquer allows you to simultaneously protect the wood and emphasize its natural beauty. The choice of varnish is the case responsible, how not to get lost in diversity and pick up exactly what you need?

Content

What are the varnishes for wood

The lacquer is called a tight substance that consists of dissolved resins and polymers - mainly in volatile solvents. If this substance is applied to any surface, the solvent will evaporate, the film will remain - dense and brilliant. Mostly varnish covered wood - one of the most beloved and popular building materials. The problem is that the tree is vulnerable to different external influences, so the varnish coating is necessary, first of all in order to extend the life of wood.

Lucky differ in the degree of gloss and applications: for work inside or outside. Properties of varnish depend on its base. For example, alkyd-carbamide varnishes allow you to create a durable coating, and alkydes - protect wood from moisture. Oil or oil hydrogen varnish will help protect the surfaces on which a large load is accounted for - floors or stairs.

The most popular varieties are parquet varnishes. For wood, acrylic and alkyd, aquatic and oil varnishes are mainly used. Wooden varnish can be bought at any construction store, after having previously studied the range to choose exactly the product you need.

A very important parameter for varnish is its shine. It all depends on which brightness of the light stream is reflected from the surface.

By type of shine distinguish:

- High gloss lacquer for wood (glitter of this means is equal to more than 90%).

- Laca glossy for wood (glitter of this means is from 80 to 90%).

- Lacomantine varnish for wood (glitter of this means is equal to 40 to 50%).

- Polish semi-seamy for wood (glitter of this means is from 10 to 15%).

- Matte lacquer for wood (gloss of this means is less than 10%).

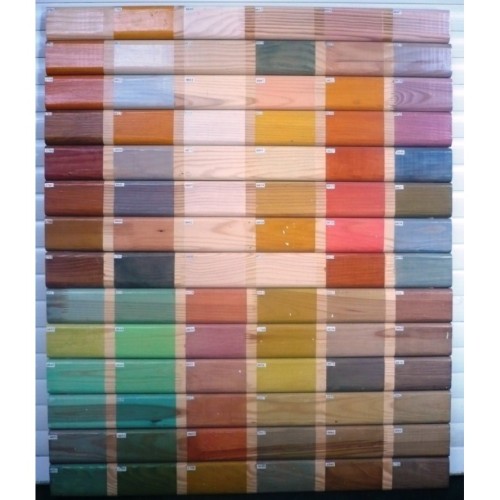

Among other things, today there are tinting varnishes - thanks to the innovation, with the help of coloring, you can change the shade and even color.

Wooden varnish: internal work

Covering a tree with varnish, you not only decorate objects, but also protect them. By themselves, varnishes are able to emphasize the dignity of wood and deepen the texture and color, and it doesn't matter where you use these building materials - whether you have a wooden floor, or the furniture, or the walls.

Specialists distinguish the following wood varnishes designed for internal works:

- Parquet.

- Furniture.

- Universal.

Parquet lacquer

A parquet board, like the parquet itself, needs high-level protection. If they are not protected by varnish, then the coating will last less than a year. In your interest, choose a high-quality tool capable of providing long-term security and simplify care - parquet varnish. This is exactly what you need. In addition, parquet, covered with varnish, looks very rich and beautiful.

Parquet varnishes have a rich assortment - their difference is based on and the effect they create. After the coating is varnished, the surface will be glossy or matte - depending on which means you choose.

Choosing parquet varnish, it is necessary to take into account the fact that you will cover this means. For example, if this is a bedroom, you can buy a varnish "simpler", because in this room there will be much less load on the floor than in the corridor or in the kitchen. In these rooms, it is best to use varnish having additional protection for the surface to which it is applied.

Choosing a varnish must be paid attention to:

- Its technological properties: be sure to consider the consistency and method of application.

- Its appearance: it can be or transparent or have any tip for a tree.

- The degree of its shine: gloss or mattness, in percentage ratio.

- Its resistance to loads, service life, light, etc.

Below you read parquet varnish views.

Wooden varnish: primer

These funds are used exclusively for the initial wood covering to enhance its clutch. The primer varnishes help if you need to get a flat shade if it is necessary to isolate wood or that the water residue does not hit the building material.

In addition, thanks to the primer varnishes, you can save, since the finish coating will need much less. True, it is necessary to make a very responsible approach to the choice of primer varnish, as it must be perfect for the finish (main) coating.

Wooden varnish: Water soluble

- Water varnish for wood use most often, because its price-quality is most corresponding to reality.

- Its composition has not only water, but also emulsifiers and solvents. But it is thanks to the water that he slowly dries.

- Water soluble varnishes differ from each other. They either do not contain solvents or the percentage of this substance is about 5% or about 15%.

- The main disadvantage of aquatic varnishes is that they perfectly penetrate all the cracks, which creates additional tallets of the floor. That is why experts advise pre-apply primer - also on water.

- In the aquatic varnishes there is also such a deficiency as very low wear resistance. But it is still possible to increase it - this is done by manufacturers, adding special additives (however, there is another "but" - such materials are applied only with humidity in the room no more than 50%!).

- In addition, anhydrous varnishes can be applied with tassels or sponges - only roller.

- As for the advantages of anhydrous varnishes, they do not have a strong specific smell due to the water content and absolutely not combustible.

Tree varnish: polyurethane

- In anhydrous or polyurethane varnishes, a high level of protection - they tend to withstand high loads.

- In addition, these varnishes have very high adhesive properties.

- Polyurethane varnishes must be carefully interfered, as they are either one-component or two-component.

- As for the basis, a solvent is used to create these funds, as well as either acrylic or uretan.

- Anhydrous varnish dries very quickly - much faster than water.

- During the application or during its drying, varnish must be secure - even a drop of water should be hitting.

- Such varnishes do not require wood primer before applying.

- Polyurethane varnishes are quite elastic.

- Anhydrous varnishes do not need a special room microclimate.

- During operation, they are not afraid of water.

- Currently, polyurethane varnish is the best means for applying to the floor, even in the room there will be a large load on the coating.

Wooden varnish: alkyd

- The basis for alkyd varnishes is natural raw materials - these are oil resins. Most often use linen and wood oils, so such varnishes are deeply penetrated into the wood and high-quality covers the entire surface.

- Alkyd varnishes are rather toxic, as their composition is included in a large concentration such a component like White spirit.

- Thanks to alkyd lacas, the tree structure is highlighted more clearly.

- Alkyd varnishes are able to strengthen the natural beauty of wood.

- Different mechanical loads are well tolerated with varnishes on an oily basis, including: temperature differences and humidity.

- Alkyd varnishes during application do not laugh in all the cracks and do not glue the boards or other subjects.

- Dry alkyd varnish is necessary at low temperatures, since it is very sensitive to high temperatures.

- Alkyd varnishes have low wear resistance.

- These varnishes are applied with a thin layer, it is necessary to strictly follow.

Tree varnish: formaldehyde

- The basis of these varnishes formaldehyde resins, which are dangerous to human health, so apply the substance is necessary in the respirator.

- Such varnishes are the most wear-resistant of all other varnish varnishes.

- Apply formaldehyde varnishes can be immediately as an finishing - without primer.

- Formaldehyde varnishes have a very good clutch with a tree.

- Formaldehyde-based varnishes are perfectly coping with temperature differences and any humidity.

- Formaldehyde varnishes can be applied by any tool: roller, tassel, etc.

- In formaldehyde varnishes, a very sharp smell is the most basic lack of their lack.

- The consistency of formaldehyde varnishes is very thick - it is strongly sticky, so the dies can be glued together.

Varnish for parquet: the Council is finally

Select room lacquer difficult? Contact your specialist who can tell you it.

But many advise such an algorithm:

- For a bedroom or children's rooms - water-soluble.

- For the living room, cabinet or balcony - alkyd.

- For the corridor, hallway or kitchen - formaldehyde.

Wooden varnish: furniture

Wooden furniture is very expensive, so specialists advise special attention to the protection of these items - for example, it is necessary to choose a good varnish.

Lacques for furniture will not only create a protective layer, but also emphasize the elegance and structure of the tree.

Today there are such products for furniture:

- Oil varnish for wood.

- Alcohol varnish for wood.

- Alkyd varnish for wood.

- Acrylic varnish for wood.

- Polyurethane varnish for wood.

The most popular and popular last type is polyurethane. It is wear-resistant and shockproof. In addition, this varnish can be used for both internal and external work.

Today, varnish manufacturers are added to polyurethane various additional substances, for example, antioxidants or ultraviolet absorbers. Thanks to high indicators, this tool is applied not only for the lacquering of furniture, but also for a wide variety of surfaces.

Plus polyurethane varnishes in the fact that they are harmless. In addition, environmentally safe. And yet - they are really transparent and do not have properties over time to yellow.

Wooden varnish: outdoor work

To protect wood, which is on the street and is subjected to various mechanical effects daily, it is necessary to use a special varnish for outdoor work. Such a means has increased protective properties and can protect wood from the external aggression, given all the individual characteristics of the tree.

Varnish for outdoor work Designed for painting:

- facades;

- garden furniture;

- arbor;

- fences;

- wooden flooring;

- terraces;

- beams and lags;

- fraps (including their crowns).

Varnish for outdoor work perfectly protects the tree from moisture and precipitation. Wooden items will serve you for a very long time - it will be enough to apply a protective layer of varnish on them.

And, despite the fact that wood lacquer for outdoor work has a higher price than the one that is created for internal works is still saving, because thanks to such protection you will definitely extend the life of wooden products!

Wooden varnish: applying tips

To make items from wood to cover with varnish, it is necessary to observe simple rules:

- Wooden surface pollut.

- If there is paint or varnish on the tree, these layers need to be removed. It is best to do this with the help of sandpaper (minimum 100r).

- If you are painted with a casting varnish, the tree can be opened with a verse.

- After grinding, dust must be carefully mixed.

- Now the primer varnish is applied - so you protect against bubbles and all kinds of visual defects coating.

- Application of varnish.

Varnish can be applied in several ways, the most common - with a roller or tassels.

- Brush. Used when applied in hard-to-reach places and when staining small elements and parts. In order not to leave traces of divorces, use a brush that has a "dissolution" at the ends.

- Roller Applied on large surfaces. Choosing a roller, note that the pile should not be longer than 5 mm.

- Spraying. The best option when the varnish is applied using a compressor and a spacing. This is the best way, as it is economical and allows you to paint even very hard-to-reach places. Thanks to spraying, staining will be very high quality.

Before applying the lacquer, mix it thoroughly, especially if the two-component means you have chosen. This is necessary for the resistance of the lacquer coating.

If you are going to put the lacquer several times on the surface, it is necessary to pass between the layers to be sandpaper (220r) and remove the dust after that.

The lacquer layers depend on what you specifically lacquer: if it is the floor, then three layers are necessary, and if the furniture, there will be enough two layers (in such a calculation includes primer).

After you have closed the surface, you need to wait for a complete drying. There is no single advice here, since it has different producers - the term is listed on the bank, so carefully examine everything that is written on the package.