Monolithic staircase with her own hands. How to make a falling monolithic staircase with your own hand Ladder

Of the many options for creating stairs, monolithic - one of the most reliable and durable. Therefore, the need often arises to make a monolithic staircase with their own hands. This process is time consuming, but if you look attentively in everything, then to build a monolithic staircase, even a non-professional, quite possibly.

Content

The concept of monolithic stairs, and their types

Monolithic or concrete ladders are distinguished by their safe design and stability. They are strong, durable and refractory. Available price allows you to install such a staircase, and the individual method of finishing will harmoniously fit into the interior of the room. The monolithic stairs, the photos of which are presented below, will clearly demonstrate the installation process.

The most suitable material for the construction of the stairs is concrete. Thanks to this, they are very durable and withstand heavy loads.

Monolithic stairs are:

- with straight marches: single-hour, two-hours,

- mr.-shaped stairs,

- screw stairs,

- p-shaped stairs

- combined.

Most public or industrial buildings use monolithic stairs with straight marchs. Curved stairs choose those who want to decorate or diversify the interior.

Tools for working on a falling monolithic staircase

In the manufacture of monolithic stairs it is very important to calculate and design each step. For work requires such devices:

- concrete mixer,

- perforator

- bulgarian,

- square with direct angle

- capron threads

- water or laser level,

- rule from two meters,

- plywood, boards,

- reinforcement

- sand, water, concrete,

- grinding machine.

Calculation and design of monolithic ladders from concrete

The calculation of the material is made according to the number of steps and width of the staircase. It is easiest to build a staircase that is located between the two walls. In this case, the markup is applied directly to the walls, and the formwork does not need to build. More difficult if the staircase adjies to one wall. Then from the second side you need to make a formwork, and from the side of the wall - marking.

Place the one-hour staircase in the house is difficult, since its installation requires a large area, and it does not always harmoniously fits into the layout of the room. Then two-hours of monolithic stairs are installed with a staircase. It will be about installing such a staircase.

To make the proper marking of the stairs of monolithic reinforced concrete with a landfill, use these tips:

- One march of such a staircase consists of at least three, and the maximum of sixteen steps. If there are more of them, it will be physically hard to climb the staircase.

- The staircase must be at least 1.5 sq.m.

- The width of the ladder itself is the width between the handrails, or between the handrail and the wall. When calculating the width of the stairs, it is important to take into account its "bandwidth" - the number of people who can rise simultaneously. The minimum staircase width is 90 cm. The most acceptable march width for residential buildings is 1-1.3 m.

- To calculate how many steps will be in the planned staircase, you need to split the height of the ceilings of two floors to the height of the steps. The optimal height of the steps 13-16 cm. For example, if the ceiling height is 3.5 m, and the height of the steps 16 cm, then for such a staircase you need 22 steps. In each opening of 11 pieces.

- The most convenient depth of the step is 28-32 cm. If you choose a width of 30 cm, then the length of the staircase march will be 3.30 m - 30 cm * 11 steps.

- 10 cm remains on the staircase. Thus, the ceiling height is 3.4 m. This height is separated by two march. At an altitude of 1.7 m, we make markup and measure the slope of the angle, measuring 3.3 m - the length of the staircase march.

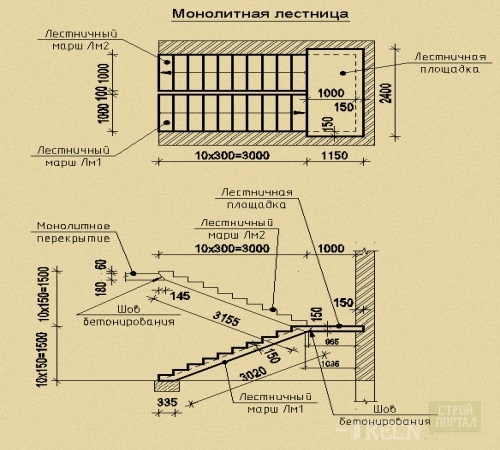

Here are drawings of a monolithic staircase:

Installation of formwork and framework from fittings

- For the construction of formwork, the basis is first exhibited. This is what concrete will be held after the fill.

- For the backup or rack, use the timing of 100x100 mm. When choosing a bar, consider the weight of concrete. The bar will be stronger, the better.

- Start the installation of formwork from the structure of the landing site.

- Ruberoid, a litter from a polyethylene film will protect the tree from moisture.

- When the staircase is exhibited, install formworks under march.

- A very important point is the knitting of the frame of the staircase from fittings. The reinforcement frame protects concrete and increases the reliability of the stairs. Use the reinforcement with a diameter of 12 mm.

- All horizontal parts of the frame are attached to the wall.

- With wire, special crochet, fasten fittings with each other. We form the cells 20x15 cm.

- Plywood, edged or semi-rubber board is suitable for forming steps and formwork.

- After placing the formwork, make the stairs to the stairs. It serves as a restricter when pouring concrete, and at the same time our future steps are attached to it. Formwork forms the final type of stairs.

- Use reinforced metal corners to form steps. They will fasten the entire wooden formwork design.

- It is very important to securely secure the lower step of the stairs. After that, spend the visual inspection of the resulting formwork.

- To remove the differences, all the joints of the plywood sheets are embarrassed by putty or grind with the plane.

Device of monolithic stairs

1. After the reinforcement frame is formed and the formwork is ready, proceed to the backfill of the stairs. Favoring options Stairs:

- slag with clay

- crushed stone

- coarse sand

- ceramizite or construction trash.

2. The raised base must be carefully aligned and tamped. Tamper sublayer, pre-slightly wetting water.

3. After the backfill, install the waterproofing so that the concrete is not mixed with the backbank and did not lose its qualities.

4. Now we proceed to the pouring of the monolithic staircase.

First poured and form the first two, three steps. During the laying of concrete, it is desirable to pronounce any metal devices to remove the resulting air cavities that will disrupt the monolithic design.

5. In the process of laying concrete, it is further vibrated. To remove all the formed cavities from the monolithic mass, the concrete is extruded through the formwork, and rolls over the surface with the help of a trowel. And thus form the future type of steps. Dropped concrete are moving upstairs.

6. The same sequence: fill, laying, vibration and re-laying apply for subsequent steps and for the landing.

7. Remove the formwork in several stages. A few days after the fill of the concrete, when it soluds enough, the formwork of steps is removed. The surface is grinning with a grinding disk or an angular grinding machine.

8. Approximately two weeks later, after filling with concrete, the ladder formwork is removed. Next, proceed to the finish.

Preparation options for monolithic stairs

There are many ways to finish monolithic stairs.

Facing options for monolithic stairs:

- natural or artificial stone

- carpet,

- mosaic,

- colored glass,

- plastic,

- clinker or tile,

- wood.

But, it is recommended to start finishing only after two months from the moment of fill.

Staircase fences are forged, wooden, plastic, metal and even glass.

Tree skin has a lot of advantages. Machi on concrete ladders are very tough and are excellent foundation for wood. Even if the steps are not very smooth, the tree will hide all these shortcomings. Monolithic wooden stairs are:

- with a decoration under the oak

- with a decoration with an array of ash,

- decoration steps beech

- finishing with various types of wood.

For finishing a monolithic staircase, the best option is oak. The only drawback is a high cost. For economy, the option of finishing the ladder from larch is suitable, it practically does not inferior oak on hardness. The most budget option is pine or spruce, they are very quickly erased on the steps.

It is best to lay wooden steps to moisture-resistant Phaneur.

If there are small children or older people at home, then the option of finishing the monolithic staircase carpet is suitable. As well as in hotels and restaurants, such ladders are carved floors. It is very easily stacked and fixed with wooden or plastic plinths. To extend the service life of the carpet - undress felt or similar material for it.

Also as a decoration of a monolithic staircase, a tile is suitable: tile, ceramic or clinker. Here you need to choose based on your preferences, design and cost.

Advice: For decoration of the monolithic staircase with tiles, the surface must be perfectly smooth. When choosing a tile, make sure that it has anti-slip coating.

When finishing a monolithic staircase, natural or artificial stones need to be taken into account both the pros and cons. It is despite the fact that this finish will last long and looks very presentable, it has a high cost and a ringing noise effect. And also behind porous rocks of stones is difficult to care.