How to make noise insulation of plasterboard partitions Walls

Installation of plasterboard partitions is a fairly common method of zoning space in the process of building and living the housing. Such structures are plasterboard sheets that are mounted on a metal frame. With their help, you can split the space and create separate rooms. As a rule, these partitions are used when redeveloping the room without labor-intensive construction work.

Content

Features of editing partition

Despite the fact that this design was invented in the USA since the XIX century, today it is gaining increasing popularity. Installing such a delimiter will cost homeowner much cheaper and will pass faster than the construction of walls from plasterboard. But at the same time, there is a need to isolate the partitions from the audio receipt. Consider the features of the use of plasterboard partitions in the interior:

- Such walls are distinguished by reliability and durability.

- After installation, the design surface is obtained smooth and does not need alignment.

- Installation is performed as a short time.

- If necessary, you can easily disassemble.

- The material has a relatively low cost.

- The design has a modern design and harmoniously fit into any interior of the dwelling.

- In addition, drywall - material that has the ability to absorb excess moisture from the air and with insufficient moisture to return it to it.

Structure of partitions

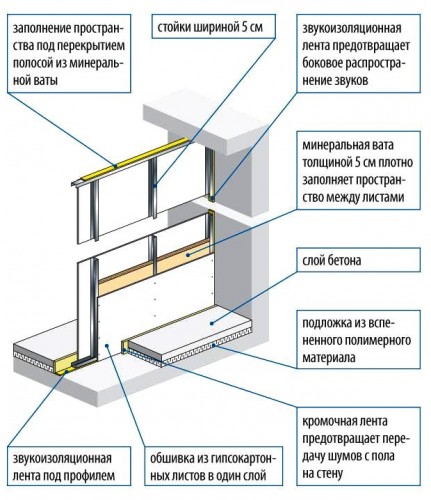

Hypotocarton partitions with noise absorption effects have a complex structure - they consist of a frame that can be metallic or made of wooden bars. Also in the structure there is a material that helps to achieve the heat and sound insulation effect. A polystyrene can be used as such a layer, which provides good heat and noise insulating characteristics.

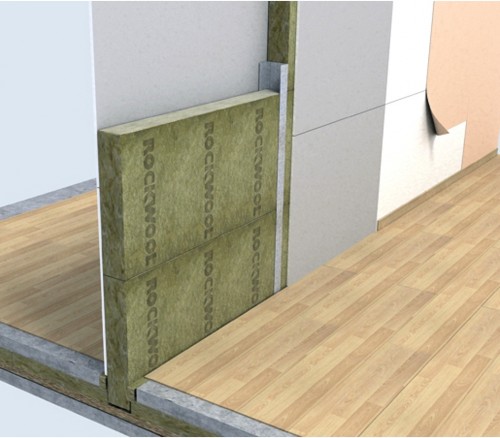

Mineral wool can also be used to achieve good insulating properties. Plates from this material are characterized by good fire-resistant, sound-absorbing and thermal insulation properties.

The supporting structure of partitions has in its composition P-shaped profiles, which are connected by special elements for fastening the plasterboard. Noise isolation in this case implies laying of sheets in two stages. The first time the material is mounted inside the design after the end of the frame assembly. The second time the plasterboard facing is fixed after laying fiberglass and mineral wool slabs.

Proper selection of materials

Before proceeding to noise insulation partitions from plasterboard, it is necessary to choose and prepare materials based on their operational characteristics:

- In order to correctly determine the width of the frame and the amount of septum required layers, should be proceeding from the level of the necessary sound insulation effect and the diameter of the communication pipes that will be inside the design. Sheets of plasterboard should choose a thickness of 12 mm.

- It is desirable to acquire only branded materials. Raw materials for them are high-quality components that do not contain toxic substances and meet adopted safety standards for the premises of the residential fund.

- Choosing mineral wool slabs you need to focus on the distance between the frame racks. In this case, the slabs will be tightly placed between sections. It is not recommended that the thickness of the wool plates exceeds the width of the frame profile.

Noise insulation for plasterboard Photo:

Tools and materials for work:

- construction plumb;

- galvanized profile;

- angular profile;

- plasterboard sheets;

- insulating material;

- tracer cord;

- frame profile;

- screwdriver;

- self-tapping screws; dowels;

- wooden bar;

- planer or cutter;

- putty.

Installation of plasterboard partitions and sound insulation

The process of the construction of the plasterboard design will not be difficult even for a novice master. At the same time, it is necessary to focus on such a sequence of actions:

- When installing partitions, a galvanized profile is usually used, the width of which is 5 cm and a wooden beam with a size of 5x5 cm.

- At the first stage of installation, we perform on the floor marking of the boundaries using the tracer cord for this.

- Next, using a plumb, the obtained boundaries must be transferred to the surface of the ceiling and walls.

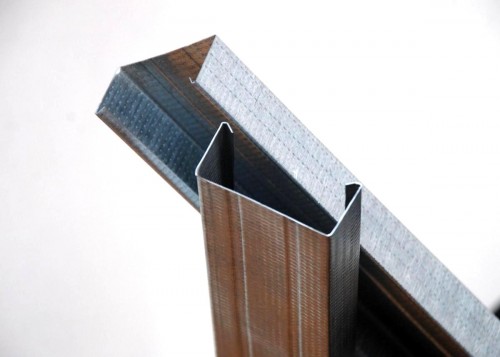

- After that, on the place of marking, it is necessary to fasten the frame profiles, which will serve as guides. The task of these profiles consists in adjusting the vector of the base of the rack profiles.

- The framework will represent the basis of the future partition. It will be mounted on the sheets of plasterboard material. Therefore, by means of a dowel, the step of which should not be above the mark of 1000 mm, fastened frame profiles.

- Then capture the rack parts to the wall surface. At the same time, to achieve a sound insulation result between the wall surface and the profile, you must fix the special tape.

- Next, using self-tapping screws, on the floor and on the ceiling, you should attach the rack profiles to the guides. The task of using these parts is to create a vertical frame rack, which will allow the fastening sheet sheets.

- Their installation into guide profiles is performed by screws. Mounting plasterboard sheets on rack profiles are needed towards an open fragment. When installing in the reverse order, the probability of bend occurs inside the shelves. To properly determine the size of the profile, it should be processed from the planned height of the partition and sound insulation requirements.

- Between the profiles of the racking in places of seams and above door openings you need to install horizontal frameworks. At the same time, make sure that the joints of the sheathing plasterboard sheets should be located on the profile.

- To enhance the rack structures inside the box, additionally paste another profile or wooden bar.

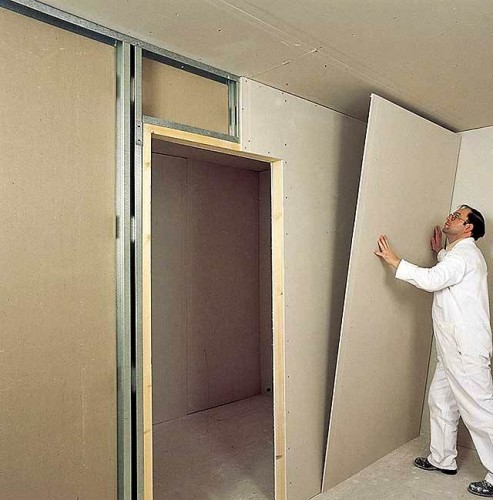

- Then, with the help of self-samples, securing sheets for the skeleton fragment. For this, all fragments need to be correctly measured and cut.

- With the help of the cutter, we make marking cuts on the surface sheet.

- Then we put the working fragment on the bar, we make the drywall and cut it off its second layer. Sliced \u200b\u200bedge will be uneven. You can correct all irregularities with the plane.

- On this plasterboard sheet is ready to install. We apply the workpiece to the frame in the vertical position and tightly press. At the same time, the mount should be carried out not only at the edges of the sheets, but also throughout the area.

- Fresh sheets to frame with self-tapping screws. To this end, it is recommended to use a screwdriver, as it will relieve from the need to drill in the opening profile.

Important! The entry of screws into the structure of the plasterboard plate should be equal to direct corner and at least 10 mm penetrate into the frame metal profile. Ships screws must be plugged into a plate of 1 mm, but do not expose the deformation material. After the installation is completed, the head should be sharpened.

To increase the stiffness of the future partition and prevent the occurrence of possible cracks on the joints, the seams of sheets must be positioned directly above the doorway themselves. In the case of the installation of partitions in two sheets, when the upper layer is arranged, horizontal seams are 400 mm. Vertical seams need to be shifted at the distance of the profile rack for the resulting steps.

16. Having finished sowing one side of the frame design, the communications should be paved inside, and there is sound insulation plates between the sheet and profile. In the case of the use of mineral wool as a noise insulating layer, the plates can be attached using an adhesive composition inside the trim and secure drywall trimming.

To prevent through the occurrence of through slots in the process of movement, wiring and communication should be skipped in elastic sleeves through the entire covering. In places of partition, where pipes pass, there should be no interruption of a layer of sound-absorbing material. It is also important that the communications be covered with soundproofing plates.

It should be noted that if in the future it is planned to install mounted parts, the weight of which will exceed 35 kg, then it is necessary at the installation phase to provide places of attachment of attachments. To do this, we should apply special deaf guopsokarton sheets. The second side of the plasterboard partition is wearing a similar way.

The final stage of work

Noise isolation of plasterboard walls requires a thorough approach to the completion of work. Not only functional, but also aesthetic design parameters will depend on this. Consider a detailed phase of action:

- In conclusion, all seams should be processed. They need to sharpen, put the reinforcing ribbon and once again apply putty.

- After drying, the surface is necessary to sand. For the processing of seams should be used specifically designed for this composition. It is not necessary to replace it with other putty, as this may later lead to cracking material.

- To strengthen the angles, it is necessary to fix a special corner profile. Exterior joints are the most weak partitions. In such places, the panels from gypsum with straight edges should be applied. But it is worth considering that it increases the risk of mechanical damage to the angles during operation. Avoid such consequences helps an angular profile.

- After processing the joints on the surface of the walls, it is necessary to apply a layer of finish putty in 2-3 mm.

- There is a possibility of appearance with time at the joints of microcracks. Avoiding this will help the execution of the finishing finish with the help of sticking wallpaper or laying ceramic tiles.

Noise isolation of walls from drywall video: