Porous ceramic blocks: characteristics, advantages and disadvantages Building materials

In Europe, the porous ceramic blocks have long pushed from its pedestal of superiority ordinary brick, in our latitudes, they have appeared recently, but immediately found favor professional builders. This material is suitable in all respects - it is easy to transport, easy to place, easy to store. Today we propose to consider the advantages and disadvantages of porous keramoblokov and talk about how to properly conduct clutch.

Content

General characteristics of blocks

The history of the invention keramoblokov closely associated with acute energy crisis that occurred during the 70-ies of the last century. While there were active search for alternative materials with better insulating properties, which could save heat and electricity. Several years of hard work, and to light a porous blocks. The first manufacturing process "warm" ceramics was patented in Italy in the early 80s. It's been more than 30 years, and today keramobloki officially produced in 32 countries around the world.

The second name of the reclined blocks, as you already guessed, sounds like "warm" ceramics. This is due to high heat-saving abilities of the material. Blocks consist of environmentally friendly components mixed with clay, and have a complete set of qualities of ordinary brick. But unlike them, the ceramoblocks are much less weighing, have the best thermal insulation characteristics, cover a large area with a smaller flow rate.

The advantages of ceramic blocks compared to brick:

- the porous structure gives better heat and noise-being;

- little weight;

- larger dimensions, which allows you to raise at home faster;

- high strength;

- durability;

- smaller solution consumption.

And if some 20 years ago, only 1-2 types of ceramiclocks were known, today they are already there are several dozen. Products are characterized by formats, dimensions, purpose, operational characteristics, etc. The most popular in construction - blocks with marking 2.1 NF, 4.5 NF, 10.8 NF and 14.5 NF. The letters of NF indicate how many times the cerarmoblock is more than ordinary brick.

Ceramic pricked blocks are used for housing and commercial construction. Of these, they build both carrier walls and partitions, parapets, fences, etc. The building built from this material will always have a comfortable microclimate, maintain heat and provide good sound insulation.

Advantages and disadvantages of blocks

The best thermal insulation properties have large-format ceramic invoked blocks. With their help, it is possible to build walls with a thickness of 38 cm to 50 cm without laying additional thermal insulation (mineral wool, polystyrene foam, etc.). Such advantages can not boast any modern building material.

The price of the invoked ceramic block may seem overpriced, but in fact it allows you to save a considerable amount. The fact that ceramoblocks do not need additional insulation we have already found out. The wall from the blocks of 50 cm thick is as warm as a wall of ordinary brick 2 m thick - saving is obvious.

They also provide good vaporizolation, protect from noise outside and perfectly prepared for finishing finish. You will not need to make a crate, mount the Faneur or plasterboard on it to cover everything with plaster or stick wallpaper - the smooth surface of the blocks has good adhesion with any finishing materials. The wall of ceramic blocks can be placed immediately or tinted with brick.

But this pleasant moments do not end. You start saving money back long before the start of construction. So, the transportation of cerarmoblocks will cost much cheaper than ordinary brick, as they weigh much less.

It is logical that any home needs a reliable foundation, that's just for a brick building you need a monolithic or blubble belt foundation, since only such structures are able to withstand the multi-torque load. For the house from the invoked blocks, it is not at all necessary to spend money on an overlooking base - you can do the use of a simplified design.

Even inexperienced self-taught builder can cope with the elementary laying technology of the masonry of hollow ceramic blocks. Large dimensions and the lack of docking seams allow not only to simplify the installation, but also to save on the solution (consumption 3 times less than in the case of brick masonry).

So, you have already saved on transportation, foundation, installation, but that's not all. When the time of the finish finish occurs, the brick walls need to be primed, smooth and in every way to improve. With the perfectly smooth and seamless surface of the cerarmoblocks, this will not happen. On the corrugated ends of the plaster is easily applied, quickly and economically.

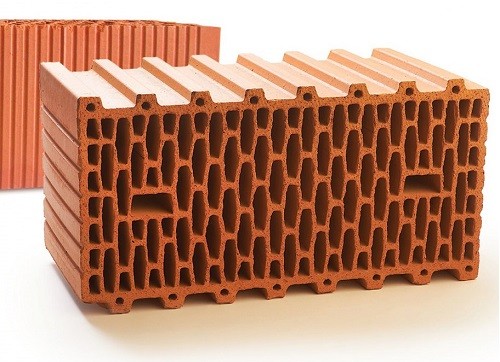

The ceramic block is a clay mixed with natural components (sand, sawdust, etc.) and foamed with high pressure, then the products are burned in a high-temperature furnace. As a result, the consumer receives environmentally friendly material with high heat and sound insulation due to the porous structure.

An interesting fact: the drawing of emptiness in the cerarmoblocks is thought out to the smallest detail and is not random. It is this layout of cavities that creates the maximum balanced heat exchange, provides vapor barrier and allows the "breathe" wall. That is why in houses from hollow ceramoblocks are always so fresh and cozy - natural air ventilation through the walls. For the same reason, the walls from the "warm" ceramics are always dry - water from precipitation and condensate quickly evaporate due to microventialation.

Let us summarize and clarify what advantages are ceramic hollow blocks:

- large sizes and, as a result, quick installation;

- substantial savings on thermal insulation, vaporizolation, sound insulation, finishing materials and solution;

- environmental purity;

- low weight;

- do not burn and do not support burning;

- resistant to deformations;

- simple installation.

Unfortunately, a person has not yet managed to invent the perfect building material without any complaints. This fate and ceramibals did not go around. The first drawback of the invoked ceramic blocks is their fragility. But here it is worth noting that if the masonry is made correctly, the load between blocks is distributed evenly, and they are able to withstand a large pressure. But if a separate "brick" is inappropriate to drop or hit him with something solid, it will definitely split. Ultimately, it is just a clay product, and the same will happen with a clay vase if it is tilted to the floor. Such fragility obliges to take protective measures during transportation and installation of blocks.

Another disadvantage is the block itself, though durable in the masonry, but has thin walls. If you look at it in the context, it can be seen that the block consists of a variety of thin partitions, so in the course of internal finishing works and the laying of communications, it is necessary to fly into the wall and score a lot of anchors and dowels into it. It will only be possible to hang the battery, a gas column, a mounted shelf, a plasma TV or something else. Simple short dowels do not solve the problem, so you need as long as possible fasteners, technique and skill.

Compared to the disadvantages of most modern building materials, shortcomings of ceramoblocks, by and large, are solved and not fatal. Just before starting to build a house of them or settle in the apartment from the hollow ceramics, the features of the treatment of this material should be taken into account.

Manufacturers of ceramic invoked blocks

Poted ceramics every year becomes more popular all over the world, but the inventors sold a patent for only a few enterprises with branches in 32 countries. When buying blocks, make sure that the products are certified and has all the necessary documents. Only in this case can be hoped for good quality. Below we will look at the two largest manufacturers of cerarmoblocks in Russia and Ukraine.

Personal blocks Porotherm

Ceramic Porotherm Ceramic Blocks are the products of the Austrian Concern called WIENERBERGER. They are made of pure natural clay on well-developed technology. As a result, blocks are perfectly retaining heat in winter and coolness - in summer, thereby reducing electricity costs. They enjoy the greatest popularity in the northern regions of Russia.

Pother steel blocks are used to build low-rise and high-altitude facilities and are considered one of the most profitable and practical materials for the construction of external walls of houses. This is an extremely economical technology that requires a minimum of temporary and financial costs. The material simultaneously plays the role of the supporting structure and insulation, and a specially designed frost-resistant solution can be used for better protection against cold.

Popotherm hollow blocks completely do not absorb moisture, so insured against refurbishment, the appearance of mold and fungi. In the Russian market, these blocks are leading among materials for pre-facilible construction.

Personal blocks keraterm

The Ukrainian leader in the production of hollow "warm" ceramics - Kuzminetskaya plant. The company was built specifically for the production of ceramic invoked blocks and was the first in the country. Experts from Italy and Spain were invited to organize the construction of workshops and debugging technology, so all production meets the highest European standards. Interestingly, the company is carried out a full production cycle, ranging from the extraction and processing of clean clay, ending with foaming, heat treatment and packaging blocks. In addition, the plant is constantly working on improving the material and developing new species.

Product Features Keraterm:

- Possed blocks are made of pure Ukrainian clay with the addition of sawdust. In the process of heat treatment, the sawdust burns out, leaving in its place the smallest pores of a closed nature, which makes the structure of the kerterma similar to the sponge, and hence it is still warmer.

- The plant's products are not inferior in quality to European counterparts, however, in contrast to them, more accessible financially.

- The quality of products is daily checked and monitored in a special laboratory at the factory. This applies not only to the composition of the blocks, but also accuracy of geometric forms.

Specificity of masonry

As mentioned above, the laying of the picked blocks is much easier than ordinary bricks, so absolutely anyone can cope with it, who will understand the theory.

How to lay cerarmoblocks:

- Since the foundation surface never turns out perfectly smooth, before laying the first row of ceramiclocks, it is necessary to prepare the basis. For alignment, apply a waterproof solution for waterproofing. It may be the usual bitumen mastic.

- Waterproofing the foundation should be as reliable as possible, so lay a roll material on top of the mastic, for example, bikrost or rubberoid. Place the clove with the surface of the outer wall, making the allowance into a couple of centimeters, and for the inner walls and partitions, make a break on both sides of future walls.

- On top of the rolled waterproofing, apply a thick layer of classical cement mortar for masonry and align the surface to them.

- When the solution is dry, apply a layer of cement over top of it without impurities.

- To lay the blocks you need a building level and rubber hammer. Place the first row starting from the corner and controlling the evenness of each brick. Do not connect the elements horizontally - each of them has to slide on top of tongue and groove type.

- After laying of the first row along the entire perimeter of the house construction leave for 12 hours to be grasped as a solution and the base it was durable.

- Laying the next series should begin the same way - from the corner.

- If necessary, the blocks can be easily sawed elektrlobzikom.

- Ligation of internal and external walls are made by means of perforated anchors, laying them in pastel seam across each row.

- To overlap the load is not passed to the partition, make bearing walls 1-2 cm above the interior, and a gap fill then the usual assembly foam.

- Of course, to build a whole house does not work, so after the completion of the clutch cover the slot elements a covering film or tarpaulin to rain or morning dew did not fill the emptiness of water in one day.

- Try to reduce the maximum relative area mortar joints, as they are potential "cold bridges" and cause of drafts. Typically precise geometry allows blocks to lay them so that the gap is practically impossible. This not only reduces the risk of heat loss, but also saves a solution (in the case of brickwork to create welds takes a lot of solution).

- As a solution, use a classic lime-cement mixture, but it is better to buy a special solution for ceramic blocks. The fact is that the limestone-cement composition is thermal conductivity several times higher than that of the blocks themselves, and this difference can adversely affect the entire thermal insulation of the building. Special mixtures have in the composition of polymer additives and plasticizers that tightly fill the bed seams and do not give cold a single chance to penetrate inside. Without such solutions, it is not necessary during the construction of rounded outdoor walls, where in the masonry there are vertical wedge-shaped seams.

The network is full of reviews of ceramic pricked blocks, and often you can find far from flattering examples - the walls are cracking, tried to drive the nail - a piece of bricks and so on. We remind you that it is possible to evaluate all the advantages and advantages of the building material. If you do not have at least minimal construction skills, it is better to entrust this work to a professional. Otherwise, all distinctive valuable qualities of the cerarmoblocks will be reduced.