Chimney do it yourself Useful advice,Construction

Chimney is a rather important design element of private houses and other business buildings, such as summer kitchens, baths. Thanks to the created natural thrust, it allows you to remove fuel combustion processes. But the process of installing the chimney with their own hands is complicated by some difficulties that you should know in advance. If you have made the decision to carry out installation work itself, without attracting additional specialists, you need to approach this case with full responsibility. In particular, it is important to calculate everything correctly. Otherwise, you can allow the smoke of the room, and even a fire. The error in the calculations can still be reflected in the load of the system, which will be more permissible, and this, in turn, the cause of the coating of the soot walls.

Content

Invalid installation of the system adversely affects the flow rate of any type of fuel, as well as on the fire safety of the entire system. Due to the inaccuracies allowed during installation work, the presence of heat lifting in the future. Obviously, this also affects the purity of the indoor air. Next, we will talk about the subtleties of the chimney mounting with their own hands.

Building regulations

Below we will list the requirements, without complying with the discharge of smoke and gases from the heating system:

- So, the chimney must be racks to heat up to quite high temperatures.

- During operation, the impact of an aggressive chemical environment is quite likely. To such conditions, the chimney should also be "ready."

- During the use of chimney, the appearance on the walls of condensate is possible. The material from which the chimney is made should be resistant to similar phenomena.

- A compulsory demand for chimney is excellent traction.

- Ideally, the chimney must have a cylindrical shape and the most smooth walls. This allows you to minimize the sedimentation of soot on the walls, which means that the need for cleaning will arise much less often.

In the manufacture and installation of chimney, follow these important rules:

- Thus, for example, the smoke area of \u200b\u200bthe chimney should at least coincide with the area of \u200b\u200bthe heating boiler pipe.

- Construction standards also indicate which material should be made by metallic chimney - should use high-quality alloy steel with a thickness of at least 0.6 cm. This steel has a number of quality useful for chimney. In particular, it is a rack to corrosion.

- According to the same standards, at the base of the flue channels, pockets should be provided in order to remove South. Their depth should be at least 250 mm.

- No less important form of the chimney itself. Not more than three turns are allowed along the length of the entire design. At the same time, the radius of rounding should not be larger than the diameter of the chimney itself.

- The total length of the design should not be less than 5-6 meters.

- In the chimney, which meets these requirements, is created sufficient to remove smoke thrust.

Choosing a suitable design

To date, there are four types of chimneys:

- brick,

- steel,

- ceramic,

- coaxial.

When choosing one or another option, it should be considered first of all the type of heating equipment, and in second - personal preferences. So, by defined with the design of the future chimney, such factors such as the temperature of flue gases should be taken into account, the pressure in the pipe created by the combustion products, the number of aggressive chemicals, the presence of condensate, the stability of the material to fire.

The cheapest option is a brick chimney, but it is not suitable for all heating equipment, but only to solid fuel heating units. Brick will be able to withstand high temperatures, which are present during the combustion of solid fuel.

If the building is heated with gas, liquid fuel or pyrolysis boilers, then the brick chimney will not fit. The fact is that due to the low temperature of the combustion, the formation of condensate is possible, which negatively affects the strength of brickwork. For such heating systems, ceramic chimney will be suitable. Its design is distinguished by strength, durability and durability. Installing the chimney with your own hands of this type is somewhat more complicated and costly than brickwork. It is important to carry out all the manufacturer's recommendations. It should be borne in mind that brick and ceramic chimneys are sufficiently heavy, which creates a significant pressure on the foundation. Therefore, they often make a separate basis, not related to the main. Because of what is for the correct installation of the chimney, special calculations may be required.

If the boiler needs to put in the room where there is no channel for the chimney, then the steel chimney is suitable for such conditions. This design is less durable than ceramic, but it can completely successfully cope with the tasks. The benefits of this type of chimney should still be attributed to the low weight, ease of installation and a relatively low price.

In addition, before proceeding with the chimney assembly, it will be useful to learn about the most common mistakes that are allowed during installation work. Some of them may have serious consequences. In particular, due to the mistakes made, there may be a fire or poisoning of residents of carbon monoxide. In some cases, it is necessary to redo a lot, which is fraught with additional costs. First of all, it is important not to be mistaken with the choice of material. For this, be sure to consider the type of heating equipment and the acidity of the medium. So, for example, the brick chimney is not always suitable. We have already spoken more about this.

Types of chimney

- Oven chimneys. One oven on average is normally able to give up no more than three rooms. At the same time, one chimney is usually made for one furnace, which ideally should be strictly horizontal, but maybe it is not always. An angle of up to 25 degrees is considered to be permissible. There should be no wooden beams in the floors, and the furnace itself should be located as far as possible from the walls and fire hazardous materials. If fire-hazardous materials are used in the roof facing, the pipe is recommended to be isolated using metal sheets. Isolate still standing furnace designs adjacent to fire-hazardous materials.

- Chimney for fireplaces. Fireplaces have a lot in common with the furnace. Therefore, the requirements for them and the technique of their installation are largely similar. Like the chimney for the furnace there should be high-quality thermal insulation. If the fireplace is needed for heating a small area, then it is possible to go through the radiator pipe. It is a design of plates, the totality of which allows to increase the area of \u200b\u200bheat transfer.

- Chimney for bath. For the bath, the isolation of the chimney is very important, so that the smoke does not get into the pair. Therefore, she needs to pay special attention. Steam overlap must be isolated, and the walls near the furnace and chimney should be led by sheet metal. In addition, it is important to minimize heat loss. For this, in particular, it must be borne in mind that the thrust should output only smoke, and not heat out of the room.

How to make chimney do it yourself

The decrease in the chimney consists of several stages, the first of which is design. At this stage, it is advisable to consistently with a specialist. When choosing a different project, first of all, it is necessary to take into account the technical features of the furnace, which is established. In addition, it is necessary to determine what material pipes for chimney will be made. For heavy chimneys, it still takes a separate foundation.

When designing, you should also consider how the ceiling beams are located. According to this information, you can understand direct you will have a chimney or bend. It is important that the horizontal parts can as small as possible. They reduce cravings and at the same time soot accumulates most of all in these zones.

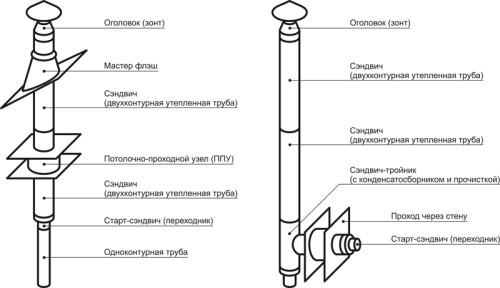

When the chimney project is ready, you can start it to assemble. If the chimney fails to collect on top, then it should be done first on Earth. Because of the high weight, you will need a hinge, which can be obtained by welding iron and pins. At the height of the chimney can be raised by means of horns and stretching. Sews on pipes and tees should be copped with a clamp. The tees themselves must be fixed by the support bracket.

At the next step, you need to prepare a pass through the roof. To do this, it is necessary to accurately determine the place where the design will pass through the roof, place this section and cut the opening. Cut is best from the inside, though, it is not always convenient to do. After that, the same hole is made in the roof. Then you can output the pipe out. The location of the passage from the inside will need to be protected with the help of the so-called cergage sheet. From the outside, the hole must be similarly protected. To regulate the angle of inclination, the conical part of the seal is used. The edges of this seal must be started under the rod of the roof. Be sure to be wasolation on the walls of the pipe. It can be performed from foil basalt formations. Moreover, it is necessary to cover the insulation layer internal cavity of the nozzle.

It remains very little. Secure the adjustable apron on the pipe, which allows you to increase the chimney to the desired length and at the same time make a mixture butt. Next, cover it with a visor so that atmospheric precipitates do not get into the design. On the parts that are most susceptible to corrosion, you should apply paint, and the joints of the clamps to make hermetic. Moreover, the paint must be a rack to high temperatures.

Safety regulations

There are several security rules that should be known before proceeding with the structure of the chimney:

- One such requirement states that it is impossible to allow the appearance of joints with other pipes. The whole system should be a single design.

- In addition, the chimney should not contact the gas pipeline and electrical wiring anywhere.

- In addition, in the design of the chimney there should be no sites located not in a vertical position. If you still do not do without them, then the length of such a plot should be at least one meter.

- During the operation of the chimney, at least two times for the heating season perform cleaning the design.

- In addition, it is important that the chimney walls to the nearest building structures were a sufficient distance to prevent fire.

- For the chimney, the thrust is very important, the strength of which depends on the ratio of its height and diameter. In the calculations of the required dimensions of the design, the type of heating equipment or furnace should be taken into account, in particular, what is its power, and at what height is the roof.

- To serious mistakes, it is possible to change the change and repair of the chimney with their own hands without preliminary calculations, as well as poor insulation. In addition, problems may arise due to errors when installing the ventilation system, which is why smoke and carbon monoxide will fall directly into residential premises.