How to sharpen chain chainsaw Instruments

Any tool needs to care. This is especially true of various saws, since their teeth have a property of age. For sharpening a hand tool, a fairly ordinary supphilya, a small machine or special nozzle for a drill. With a chain for chainsaws, things are a little more difficult. Next, let's talk about the intricacies of this process.

Content

Technical characteristics of the teeth chain chainsaw

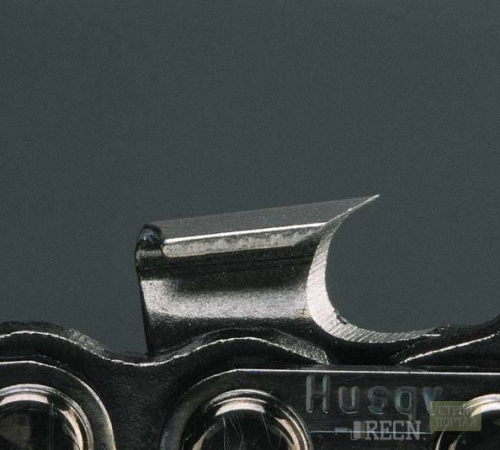

The first thing that rushes into the eyes is a complex geometric shape. If an ordinary cutter resembles a triangle or a strongly elongated oval, then the tooth benzopils is much more complicated. It consists of two cutters located perpendicular to each other. The first cutter is similar to the usual tooth. It is necessary in order to make an incision in the tree. Further, the second cutter enters, similar to the letter "g". This form is necessary in order to evenly choose chips from the tree and make a wide propyl, protecting the chain from pinching.

It is the chain of chainsaws, not a teeth, is the most important criterion for high-quality and easy work. Therefore, we consider it in more detail, since the reason for the performance drops often occurs due to the inconsistency of the chain to the tasks.

- step interval,

- number of links

- their thickness

- planned range of work.

Step interval is the main and main criterion when choosing a chain. Highlight chains in step:

- 1/4,

- 0,325,

- 3/8,

- 0,404,

- 3/4.

Step 1/4 is the minimum permissible. The chain with such a step is designed to perform the simplest household tasks, such as cleaning fruit trees, and can not be used even for harvesting firewood.

Steps 0,325 and 3/8 are standard for most European and Chinese manufacturers. Such a step allows you to perform a fairly wide range of works, up to spillation sufficiently thick, more than 2 m in diameter, trees.

Steps 0,404 and 3/4 are used for the production of industrial equipment. If you plan to use chainsaw for regular sawmills of forests, billets of thick lanes or works associated with the cutting of trees, then the choice of one of these steps is more than justified.

There is directly proportional dependence between the chain step and the performance - the more step, the larger the teeth. Consequently, the sawing is performed easier and faster.

The more links, the easier it is to cut. Therefore, their number also matters. But even more important than the thickness. Seat teeth:

- 1.1 mm,

- 1.3 mm,

- 1.5 mm,

- 1.6 mm,

For a domestic consumer, a teeth with a thickness of 1.3 mm are optimally suitable, but if the saw is planned to be used for logging, it is better to take 1.5 mm.

If the chain on chainsaw meets the stated requirements, but the performance of the work has decreased, then it has come for sharpening. In all other cases, it is more appropriate to purchase a new chain.

Sharpen chainsaw with a manual method

The easiest way to return to the teeth with chainsaws sharpness is to use the file. For this you need:

- remove the chain from the saw

- remove oil, sawdust and other garbage,

- wipe the chain dry rag

- prepare small and large files,

- to sharpen.

Of all the actions, it is most important to completely clean the chain from dirt and oil. It is done not only to not stain hands and clothes, but also for a detailed inspection of the chain and links. Very often between the teeth or in them, sins remain. This, in turn, reduces chainsaw performance.

Since the tooth consists of two separate elements, each of them must be sharpened in its own way. The upper cutting edge has a conical one-sided sharpening. At the same time, the sharpening angle must be not more than 30 0 and at least 15 0. The less the angle, the easier the saw will be in the wood. But it is worth remembering that a smaller angle indicates a smaller thickness of the metal, which means that the steel will be blown up faster. The choice of sharpening angle depends on the tree breeds with which it is planned to work.

- For solid rocks, such as oak or larch, need sharpening angle of 30 0.

- For soft breeds, such as pine, fir and most garden trees - 20 0.

- If you plan to use chainsaws only for trimming not very thick branches of fruit trees - 15 0.

Guide tooth in most cases has a bilateral sharpening. The angle of inclination of the cutting edge is not as important for it, but it should be taken into account that it is impossible to do it too small or too large. The optimal value is all the same 30 0.

Sometimes elite chainsaw models are equipped with a stressed blade teeth. Visual, this amplifier is easy to determine. An additional cutting edge is attached to the edge of the tooth, excellent in color and texture. If the element is detected, you do not need to sharpen the chain chainsaw. Since the amplifiers are based on superproof alloys, which are not manual sharpening. Consequently, the chain will have to be replaced.

Flying Instructions:

- prepare a large and small nooduli,

- clamp a plot of chains in visets or with a clamp,

- sharpen the top cutting edge

- move the movement from the body to the tooth, to the edge,

- get the guide edge

- movement from the body to the edge alternately by changing the parties.

When performing this work, it is very important not to change the direction of the movement of the file, otherwise the blade is fastened even more than before performing sharpening. This principle of operation is valid for handmade and automated.

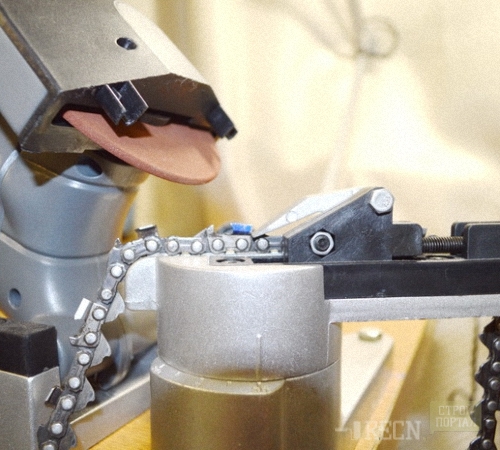

Sharpen chainsaw with a chainsaw

In order to manually sharpen the chain chainsaw of medium sizes, you need at least 6-8 hours. Therefore, it is more expedient to resort to the help of electrical appliances. There are two options:

- drill with a special nozzle

- grinder.

In the case of a drill, you will need an ordinary nozzle "Grinding stone". In this case, the width of the nozzle should be greater than or equal to the tooth blade plane. Otherwise, the sharpening will be completed unevenly. In addition, it should be noted that the surface of the grinding stone should be smooth, without rounds or defects.

This method has one significant drawback. There are no grinding stones for teeth chainsaws, so you have to make it yourself, by grinding more than standard stone, or use special "grinding stones". They are significantly less grinding, consist of less durable material and spend fast enough.

Nevertheless, less strength allows not to overgrow the metal, as a result of which the strength of steel is not lost. In the event that a grinding stone is used, after every two or three sharpeners, the tooth will have to cool. In the water, the chain can not be put, so it remains either a fan or slices of ice wrapped in a rag.

The grinding machine is a much more powerful unit. Therefore, it is recommended to work with it only professionals. If we are talking about a standard household grinding machine, then with it, it turns out to sharpen only the upper cutting edge. This is primarily due to the gabarites of the unit. However, even if the machine is to sharpen only half of the teeth, it will be necessary two times less.

If it is planned to use a sharpening-grinding machine not only for sharpening knives and drank, it makes sense to get a small low-power unit like the boron of the car dentist.

This setting is significantly less and is intended for carving wood, metal and stone. Including, it is easy to adapt to sharpening small parts. On the market, the cheapest models start from $ 300. Therefore, the purchase is appropriate only if the machine will really use.

In addition, there are special machines for sharpening chains chainsaws. Their cost is also high enough, so there is no point in buying for private use.

Chainsaw sharpening chains

Although the procedure consists of all of several actions, it is worth understanding that this is quite a long, monotonous, painstaking work. The slightest error will lead to the fact that the tooth is spoiled. This, in turn, will be the reason that the chain will burst during work and cause injuries. If a powerful saw is used, then the chain fragments are injured not only the employee, but also scatter on the radius of 10-15 m.

It makes no sense to carry the chain for the reason that this work will have to give at least 300 rubles. In addition, without feedback and recommendations, "specialists" for calibration are often ordinary halmiers. Therefore, there is a risk of getting back spoiled chain and stay without money.

On the other hand, new chains are from 200 rubles. These are small money, so it makes sense to weigh everything "for" and "against" before starting to work. If it was decided to buy a new chain, it is better to choose an option with a reinforced cutting edge. Such products are 3-4 times more expensive, the service life is much more and up to 10 times the usual chains.

It is really relevant to sharpen the chain only if the work is required immediately, and there is not a single construction hypermarket or bazaar nearby. At the same time, the manual sharpening method prevails over the machine, as it allows you to get a better and durable cutting edge.

Tips for extending the life of the chain chainsaw

Take care of the honor with the Moldus, and the thing is a dream, as folk wisdom says. This statement is particularly relevant for stitching and cutting items, since at home to achieve factory accuracy is not possible. In order for the chain as much as possible to be acute as possible, remember the following rules:

- Regularly lubricate the chain of oil. It is done in order to ensure the smoothness of the stroke and prevent corrosion. With regular work, the procedure is enough to repeat once every two weeks. If the saw is rarely used, it is more expedient to remove the chain and soak it in machine oil.

- Singing strictly perpendicular to the earth. Despite the fact that chainsaws work at any angle, the standard requirements for working with the sawing tool are fixed by a certain rack. Sawing is performed perpendicular to the ground, the sawing edge relative to the tree is located at an angle of 45 0.

- Give metal cool. Any steel when heated loses its strength. Even the so-called, calene iron, it turns out by heating steel to the boundary temperature and immediate cooling, it becomes heavy durability only once. If you repeat the procedure, the metal will lose its properties. Since most chains are made from relatively cheap technical steel, it instantly leads to the blurring of teeth.

- Inspect the chain after the end of work. Frequently often in it remains small sins or chips. If they get up in a strut, then change the geometry of the tooth, therefore, it will start working incorrectly and at best quickly fool around, and at worst it will break.

- Store saw in a dry, well ventilated room. Even oil-treated chain quickly covers corrosion, if it is constantly outdoors. Ventilation is needed so that moisture from the air indoors did not have time to settle on the chain.

- Do not beat the saw on wood, stone or other surface. Despite the evidence, this action is often performed automatically, in order to reveal the sawdust. It is categorically impossible to do it, since burrs appear on the cutting edge, which are quite difficult to eliminate. Without correction of this defect, the performance performance falls by 20-30%.