How to make waterproofing on the balcony? Insulation,Floors

Many tenants glazed their balconies and loggias and increased their apartment for another small room or additional storage room. But in the open balcony there is its own charm: at the same time at home and in the fresh air, it is good here to stay among the colors and observe how children play in the yard. In addition to the lyrical side of the case there is prose. So that the balcony was a cozy corner, he needs protection, because all the burden and attack of our harsh climate are collapsed on it. In the summer - heat and rains, winter - frost and snow. The temperature difference and atmospheric precipitations gradually lead to the cracking of the floor, the appearance of mold, corrosion of reinforcement, the destruction of the supporting structures. The floor on the loggia or the balcony is also the ceiling for the neighbors below. Hardly they will enjoy the drips on the walls and the ceiling. To avoid such problems, you need to conduct waterproofing in the loggia or balcony.

Content

Where waterproofing is required

Waterproofing is a complex of protective measures from the destructive action of moisture. Waterproofing is used to increase strength, extend the life of buildings and structures. In waterproofing, not only balconies, loggias and other open structures are needed. The moisture enters both precipitation and filtered from the basement and soil, in connection with which the floorproofing of the floor is necessary on the first floors of all buildings for the prevention of the flooring from deformation and rotting.

Waterproofing is needed in high-rise buildings to eliminate water flow from the upper floors to the lower, especially in the kitchen or bathroom, where the high probability of water leakage.

The principle of waterproofing is to create dense and a durable layer with waterproof and water-repellent properties to protect the concrete base and floor covering from the negative impact of moisture.

In a wet climate, waterproofing of the foundation, basement, cellar walls, attic, roofs are necessary.

Types of waterproofing

Depending on the method of implementing and used building materials, there are various types of floor insulation:

- Plaster. Designed for coating reinforced concrete structures.

- Caution (paint). Multilayer coating from bituminous paints. Used to protect metal structures from corrosion.

- Cast. It is considered the most reliable type of isolation. It is placed from mastic and asphalt solutions with a layer to 5 cm.

- Powered. It is performed by gluing a special waterproofing material.

- Mounted. Special plastics or metal sheets are used, profile tapes that are attached to the building design. It is used if the other type of waterproofing cannot be applied.

- Impregnating. With this method, construction products from porous materials are impregnated with organic solutions (polymer varnish, bitumen, petrolatum and coal pitch). Apply impregnating technology for processing prefabricated materials (asbestos-cement sheets and pipes, concrete slabs, blocks of tuff, concrete, limestone).

- Fucking. It is a special cavity filled with bulk waterproofing material (asphaltizol, hydrophobic powders, sands). The thickness of the layer reaches 50cm. The flowing layer simultaneously performs the function of hydro and thermal insulation.

- Injection It will be performed by the method of injection of a special binder solution (furanum resins) in the seams between concrete blocks and cracks. Injection waterproofing is used most often for the repair of already existing waterproofing. _______________________

Lata waterproofing

This is a reliable and fairly expensive type of waterproofing, which is performed from mastic and asphalt solutions. Distinguish hot and cold waterproofing.

The method consists in casting a mixture along a horizontal solid base in 2-3 layers of a total thickness of 25mm and formwork on walls with a thickness of 3-5 cm. For its manufacture, foamipoxide, asphalt ceramic concrete, bitumerticity and various foams are used.

Operating procedure:

- The floor is cleaned from dust, dirt and sand. If necessary, with the help of plaster potholes and cracks are embarrassed.

- The surface is dryed by hot air. The surface is groundborne to a liquid state bitumen. On the perimeter of the room are installed flights with a height of 30-40cm.

- Mastics are heated to 140 ° C and flooded the floor.

- Mastic leveled on scrapers. For a long service life of waterproofing, the mixture is applied in 2-3 layers to a thickness of 25 mm.

- To increase the strength of the waterproofing layer, a metal mesh or fiberglass is additionally used.

Cold way. Use the mastic of cold waterproofing is convenient, quickly, without additional costs.

The concrete floor is cleaned before applying the waterproofing composition, remove the garbage, remove the oil collapse, align the defects with plaster. After complete drying, the surface is covered with soil. All over the perimeter of the floor is the fencing with a height of 30-40 cm. The waterproofing mixture is poured on the floor and the scraper is aligned.

Painting (coating) waterproofing

It is a subtle no more than 2mm multilayer coating from bitumen and polymeric paints and varnishes. Designed for anticorrosive and anticipillary protection of reinforced concrete and metal structures.

Refractory waterproofing is two types:

Cold - based on epoxy rubber resins.

Hot - with the use of bitumen-polymer varnishes.

Operating procedure:

Before applying the insulation composition, the surface is cleaned from dust, drowshes and traces of corrosion, degrease. Apply primer from bitumen liquid mastic in two layers.

Then the floor is painted with bitumen or polymer varnish with brush and roller. As a result, a rather thin layer of 2mm thick for protection against corrosion and fungi is obtained.

The method of painting waterproofing is increasingly practiced in recently with the advent of new moisture-resistant materials with higher protective characteristics, simplicity and ease of use.

Materials with a bitumen content are inexpensive and enough easy to work, but their service life within 5 to 6 years, at low temperatures, the bitumen becomes fragile.

In this regard, preferably various polymers on a bitumen basis: bitumen-rubber and bitumen-polymer compositions.

Waterproof waterproofing

it is performed from rolled and sheet materials, which are glued at 3-4 layers to the surface treated with soil. Equal waterproofing is three types:

- Bituminous-polymer - Isoplast, Philipol, Arobitel, Bikroplast, Ecarbits.

- Bitumen-rolled - foloisol hydrohoteloisol, isol, hydroizol, rubberoid.

- Polymer - polypropylene polyethylene, polyvinyl chloride, synthetic rubber, highway.

When choosing a material, it should be borne in mind that the temperature of the softening of bitumens and polymers should exceed 25 degrees air temperature. The waterproofing layer is protected from mechanical loads with a concrete screed or brick design. If it is impossible to make a protective design, then you should choose another method of waterproofing.

Procedure for performing work:

- A layer of bitumen mastic with a thickness of 1 mm is applied to the clean dry surface.

- Rolled and fixed roll.

- To obtain a multilayer coating, a mastic layer is again applied and covered with a rolled roll and so the required number of times. At the final stage of work on floor isolation, roll edges are processed by moisture-protective putty with polymer additives.

Air temperature, building materials and processed surfaces when performing waterproofing work not lower than + 10c.

Such waterproofing is suitable for protecting concrete and wooden floor.

The inlet method is still widespread, but gradually inferior to new hydraulic protection technologies. This method has serious disadvantages: preparatory surface treatment, high complexity of laying, sharp stable smell, uncomfortable dimensions and heavy weight of rolls. In the fields of joints, the adjoins of the parapet and the walls inevitably arise to the seams and bendes, which subsequently become sources of leakage. Rolled materials are not resistant to temperature fluctuations and microorganisms.

Plaster waterproofing

Materials for plastering waterproofing are cement solutions and polymer mixtures. The obvious advantages of plaster waterproofing: simplicity of laying and the possibility of widespread use.

Procedure for performing work:

- The surface of the floor is cleaned and, if necessary, flushes, is ground and dried. A solution of cement and sand is prepared in a 1: 2 ratio.

- The first layer of plaster with a thickness of 10-15mm with a gripping of walls and careful corners is applied with a brush or spatula.

- After 15 minutes, when the plaster is dry, the following 3-4 layers are applied in the same way. Mechanical loads should be avoided for a plaster coating for two days.

- In the process of solidification, the plaster layer is not allowed. On the first day, the insulating coating is moisturized with water from the sprayer every 3 hours, and then 2-3 times within two weeks.

Such waterproofing is widely used to protect facilities from reinforced concrete. For waterproofing, hot and cold asphalt maps and solutions, cement torch, which are stacked without protective sides and allow mechanizing the workflow. Polymer-cement coatings, colloidal cement solutions have proven well. When working with waterproofing compositions, it is necessary to accurately follow the instructions for use.

Plaster waterproofing is durable and well combined with other finishing materials, such as ceramic tiles.

Sex waterproofing on the balcony

As a rule, the balcony or loggia area is small, and the new efficient hydrophobic building mixes are easy to use, so it is quite easy to perform waterproofing of the floor on the balcony or loggia. The main thing is to clearly observe the technological chain and correctly handle the material.

Floor waterproofing on the balcony can be made in different ways and materials, depending on the state of the floor and the readiness of the homeowner to physical and financial costs. If there is already obsolete on the balcony, the waterproofing coating, it is removed, and if it is under a tie, the screed is dismantled too. Sometimes, you can do with semi-dimensions and make waterproofing the balcony over the finish coating, but it gives a temporary effect and spoils the appearance of the balcony. It is best to initially choose products of good quality and make durable waterproofing.

Types of floorproofing floor on the balcony

First you need to make sure that the balcony normal conditions for the drainage. The reverse bias (to the wall) of the balcony plate and damage is eliminated by a screed of cement and sand taken in the ratio of 1: 3. The concrete solution is applied to the surface of the balcony plate, pre-purified from dust and dirt and moistened. Alignment is made at an angle of 1-2 ° with a slope to the outside of the balcony.

The waterproofing mixture is applied over the screed to protect the balcony of the negative action of moisture.

If there is no problem of the opposite slope and the strong destruction of the concrete slab, then you can do without a screed, it is enough to limit the floor with waterproofing. It is very important to choose high-quality and durable waterproofing material with high moisture resistance, heat resistance, strength, elasticity, resistant to the action of acid rain, ultraviolet, microorganisms, mechanical loads.

Painting waterproofing hydrophobic mastic is a simple, convenient and advantageous way. For the waterproofing of the floor of the balcony, the polyurethane mastic hypersmo will be a suitable option. Service life of 25 years. Its properties of hypertension retains at temperatures from 50 to + 100 °. This mastic is well unlocked with all the surfaces and is convenient in applying. Hyperdesmo is a single-component composition, easily applied with a brush or roller.

HypeRizable waterproofing technology:

- The base is cleaned of dust and dirt.

- Cracks, seams, joints of the plate with a wall closed with a polyurethane sealant (Rebbarflex, Emphimatics PU-15).

- The surface of the balcony slab is first processed by primer (wagon).

- Mastic stacked in two layers.

- To control the quality of the coating, it is recommended to make layers of contrasting color. The second layer of mastic is applied after the total polymerization of the previous layer. Mastics are missing.

- As a result, a seamless coating is obtained. For solidification of mastic hyperdessum, 6-8 hours are required.

- If the tile laying is planned over the hyperschemese, then to obtain a high-quality clutch with tiled glue, the upper layer is immediately sprinkled with quartz sand, without waiting for drying. Sand surplus are removed by a vacuum cleaner or broom. It turns out a rough surface. On top of this layer with tile glue, the tile is glued and topped with a load for greater strength.

In comparison with rolled calain materials, the steastal waterproofing of the balcony is more expensive. But the service life of rolled waterproofing on average for 2-3 years, then it begins to flow through bundles and bloating.

Sample Balcony Waterproofing Technology

The balcony is running on the second floor of the cottage. The floor is covered with ceramic tiles, water penetrates through the seams, floats the veranda from below.

Stages of waterproofing work:

- Full disassembly tile, screed and old waterproofing layer.

- Laying a new screed.

- Layer of heat insulation.

- Flooring under waterproofing from OSB plates. Primer processing.

- Applying the first layer of polyurethane mastic, starting from the wall to a height of 15 cm. Print geotextile.

- Applying the second layer of mastic.

- Processing by the polymer binder composition and chip covers.

- Finish structural light-resistant varnish.

Waterproofing loggia

Work on insulation and waterproofing of loggias pass in parallel and consist of several stages: glazing of loggia, waterproofing of brick or concrete partitions, floor and roofing.

The most rational insulation and waterproofer for jumpers and walls is foil polystyrene foam. This material is glued with a special construction frost and moisture-resistant mixture. For even greater moisture protection, such a coating is treated with waterproofing composition. The choice of material depends on the structure of the surface being processed. On concrete bases, penetrating compositions are used. For the waterproofing of brick, stone, polyurethane surfaces are used by coating compositions. For partitions, coating or elastic mixtures are suitable.

Operating procedure:

- The surface of the partition is moistened.

- Brush is uniformly in 1 mm, the first layer of coating composition is applied.

- After six hours it is applied the second layer of waterproofing perpendicular to the first.

- A reinforced grid is used for interputric seams.

As a result, an elastic coating is formed, fully excluding moisture penetration.

Waterproofing the ceiling of the loggia

- Defective areas transmitting water.

- A weak cracked concrete layer is removed. The base should be clean and durable.

- Cracks and interpanel seams close up with a special polyurethane sealant. For large cracks, mounting foam without toluene or polyethylene seal is used.

- The metal brush is cleaned the ceiling from dust, dirt, old paint and fat spots.

- After that, the penetrating waterproofing mixture is used to protect concrete coatings from water, frost and cracks. It can be different and contains special additives, sand and cement. The mixture is able to penetrate the depth of concrete by 9 cm and form internal solid crystals with moisture protection properties.

- The ceiling is moisturned and coated with a penetrating mixture with a brush. After the solution grabbed, the process repeats the process again.

- The penetrating waterproofer affects the skin and mucous membranes, so gloves should be put on gloves and protective glasses. Within 3 days, the surface is moisturized from the sprayer and are covered with a plastic film without allowing a drying.

- For more reliable hydro and thermal insulation, polystyrene plates are installed using construction glue and fastening accessories. Interputer seams are filled with mounting foam without toluene and sinking tape.

Waterproofing floor loggia

The waterproofing of the floor of the loggia is especially necessary for apartments on the first floor. Such waterproofing serves as a barrier from moisture penetrating the basement or soil.

- Sealing seams.

- The coating is cleaned and wetted with water.

- Primary penetrating composition.

- After drying, re-moisturizing and processing penetrating mixture.

- Laying foil vapor polypoletor.

- Established a wooden bar.

- Attaching OSB-plates with self-proofs to Brusa.

- Installation of floor covering.

After completion of major waterproofing, it is proceeded for finishing work.

What to make waterproofing floor on loggia

Bituminous materials: Elastopaz, Rapidflex, Elastomix are intended exclusively for waterproofing and do not withstand intense mechanical loads and are not particularly aesthetic, as black rubber is reminded. Therefore, a concrete screed or other carrier material (plywood, chipboard, etc.) is arranged over the waterproofing. When the floor is used, waterproofing is covered with geotextile to protect against mechanical damage.

In order for the waterproofing of the floor to look beautiful and it was possible to walk along it, they apply asopase mastic from TEKHNOPROK LLC.

Polyurethane composition for waterproofing of the floor of the Flood is a two-component mastic with a water-based activator. The liquid activator is poured into a tank with mastic and mixed. It is recommended to spend the mixture for two hours. Mastica pour into the floor and squirt. Consumption - 3kg / per sq.m. As a result, it turns out a polyurethane white screed, seamless, waterproof, resistant to abrasion and pleasant to the touch.

Materials of penetrating action Penetron effectively protect concrete structures from moisture. Moreover, the more moisture falls on the floor, processed by the means of penetron, the stronger the protection.

Waterproofing floor in the kitchen

The kitchen refers to zones with high humidity, as there is a plumbing, dishwasher and washing machine.

Waterproofing of the kitchen floor can be performed in several ways:

- Breakened waterproofing with rolls based on bitumen: uniflex, rubberoid, technoelast. The concrete screed is laid on top.

- Painting waterproofing using mastics on a bitumen basis: hydrolyx, elastomix, elastopaz. Top of several insulating layers also fit cement screed.

- Plaster waterproofing based on cement-polymeric solutions: Tocan, SK-106GB, master barrier, on top of which tile is pasted.

- Polyurethane Mastic Waterproofing: Hyperdessum, Reamast-Ls, easy to apply, quickly dries, provides reliable waterproofing.

Waterproofing floor in the kitchen in the panel house

According to the construction technology, overlapping slabs in the panel houses are smooth only from the ceiling side, the surface of the floor is uneven, litter. To align the floor make a tie. Before laying a screed, concrete base is carefully dusty, moistened or ground. Before laying a screed in the kitchen, we necessarily make the floorproofing of the floor to completely eliminate the slots and prevent the water leakage.

Waterproofing of the floor under the cement screed is carried out by the coating or inlet method. The basic rule for the floorproofing of the floor is the creation of a pocket: the processing of the base of the room with the allen on the walls is 10 cm. If the waterproofing is adjacent to the spawning, then it is raised in the corridor for another 30 cm.

One of the options for waterproofing the floor in the kitchen - rolled film (hydroisol, polyisobutylene, PVC film). Rolls are stacked with adhesive 20cm. All joints, seams and adjustment to the walls are processed by a revincible mastic. After filling the screed, all surplus rolls are cut.

Another effective method of waterproofing of the kitchen floor - treatment with a mixture of penetrating action. According to the instructions on the package, the mixture is diluted with water and is applied with a thin layer on a concrete base, with the second layer - perpendicular to the first. It turns out a seamless waterproof coating. To activate water-repellent properties, the insulating layer is moisturized within two days. After that, put the screed.

Waterproofing for a warm floor in the kitchen

Waterproofing for warm sex in the kitchen must comply with increased quality standards and safety standards.

- Absolute water and parangarity.

- Hydrophobicity.

- High adhesive properties.

- Heat resistance.

- Inertia to the action of chemicals.

Waterproofing floor in the kitchen in a private house

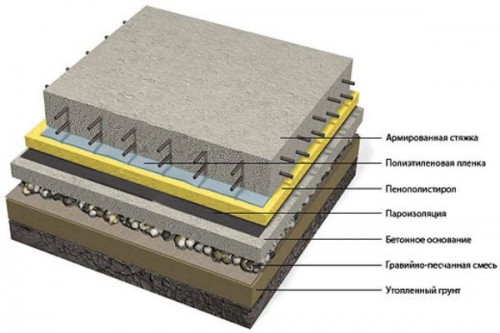

Waterproofing floor in the kitchen in private dominates its features. The capillary moisture from groundwater penetrates concrete, wood or porcelain stoneware, has a destructive effect on the structure of building materials. In such cases, 2 types of waterproofing are used: flowing and inhibition. A sandy-gravel pillow is created under the floor to a half-meter thick, which is closed with a rolled waterproofing with an adhesive on the wall to 10 cm. The next layer is a concrete screed, and the final - flooring. Waterproofing the floor in a private house is recommended to do in all rooms, regardless of their purpose, in order to avoid high humidity, damage to floor coatings.

Reliable barrier drop that sharpens a stone

Waterproofing is a type of construction and repair work that requires a serious relationship and careful implementation. Qualitative materials, competent selection of waterproofing method and made at the conscience. Work is a guarantee of reliable protection of the house from dampness for many years.