Installation of imitation of timber Walls

Having decided to change the external or inner appearance of your home or cottage, but at the same time to insulate it, pay close attention to the well-proven inexpensive material - imitation of the bar. A boom of using artificial materials in the decoration was held, and now for insulation and giving an aesthetic type of buildings more often use the finish by environmentally friendly natural materials. The outer finish of the simulation of the bar gives the structure of the appearance of a good-quality wooden house, that is, visually the impression is created that the building is built from a calibrated bar on Finnish technology.

Content

Specificity of production of fraud

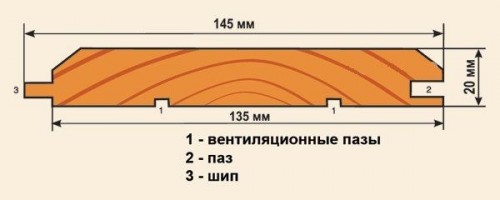

The imitation of a bar is a type of lining, but on the simulation board there is no specific deepening (shelves), both on the Eurolution, and the board itself is wider and thick.

At the end of the 20th century, domestic GOSTS were developed, regulating the attribution of lumber to a certain variety, however, modern processing of wood on imported woodworking machines has its own specifics, therefore, the standards of thirty years old are often not applicable. In this regard, many manufacturers of materials from wood are developing their technical specifications to the imitation of timing to a certain variety. If the surface of the material is too smooth and smooth, it will create the illusion of its artificiality, and if there is an excess of bitch and flaws on the board, then the aesthetics of the appearance will suffer, and the material will seem unfounded. These nuances imply the need for the production of brushing imitation to adhere to the "golden middle" and determine the assignment of finished products to various varieties in two criteria:

- the presence and amount of flaws and vices of wood on the board;

- The degree of mechanical damage to the wood at the processing stage.

Varieties of imitation of timber

Generally accepted division of material for three varieties, but different manufacturers can marked material in different ways:

- "A" ("Extra");

- "AV" ("Classic" or "B");

- "B" ("Economy" or "C").

Grade "A"

The highest grade imitation variety. The boards strictly correspond to the design parameters, the surface is smooth and smooth, the flaws of the wood is minimal. Complete lack of mechanical damage in production.

Grade "AV"

High-quality profile with a small amount of resin pockets on the surface of the board whose value is not more than 3 mm. The presence of 1-2 bits of light or dark color on the 1st item of the product is allowed.

Grade "B"

The least high-quality imitation of the bar, but also the cheapest variety of it. In the geometry of the groove and the ridge are possible deviations. The surface is not perfectly smooth and smooth, the presence of 2-3 resin pockets and several bitch on the surface of the board is allowed. Some manufacturers on this material grade allow small mechanical damage to the processing in the form of chips and cracks.

With the outer and inner lining of the walls, the imitation of the residential buildings use varieties "A" and "AB". The "B" variety is used when finishing auxiliary surplus buildings.

The main advantages of the material

Recently, the popularity of the imitation of the bar, as a finishing material, is growing in geometric progression. Such a demand is explained by a number of important advantages of this lumber.

1. Ecology. The material is made exclusively made of natural wood without artificial impurities.

2. Easy and speed of installation.

3. Resistance to temperature drops and durability. The drying of the material is made in specially developed chambers, which makes it possible to achieve increased wood stability in conditions of changes in temperature and prevent cracking of timing of timber.

4. Easy. The weight of the material is much lower than the natural calibrated timber, so additional loads on the design and the foundation are minimal.

5. Durability. In addition to drying at certain temperatures, the material is impregnated with a special solution, which significantly increases the service life of the boards.

6. Low finishing cost.

How to choose a timber imitation and fasteners

Most often in the decoration uses imitation of a bar from larch, Angarsk pine and ate. If you have special carpenter skills, you can make a timber imitation with your own hands, and then you will not have the need to choose between different manufacturers and varieties of material. If there are no such skills, it is better to know the main selection criteria.

The market presents a large range of this sought-after material, but sometimes it is not better quality. Therefore, be careful when choosing and buying boards, pay attention to the following characteristics:

- humidity that should be no more than 15%;

- the presence of deepening on one side of the board, which ensure the correct air circulation;

- if the imitation of a bar for interior decoration is acquired, then it is better to buy narrow boards, which will significantly save money;

-For installation of the simulation of a bar need to acquire reliable fasteners: nails, selflessness, dowel, kleimers.

How to strip timber

Of great complexity, the timber installation process does not represent, since each board is equipped with a groove, and with another ridge, and you can try to install timber imitation with your own hands, which will reduce the cost of finishing the building. If there is no confidence that you will succeed quite well to perform fasteners, it is better to hire specialists, but at the same time familiarize yourself with the subtleties of installation and unobtrusively control the process of fastening the imitation of the bar.

After buying a material, at least 7 days should pass so that the boards are acclimatized, it will save wood from subsequent deformation and cracking. Next, you can proceed to the installation process.

1. The waterproofing material is mounted on the wall.

2. Next is mounted a doom. Wooden bars with a thickness of at least 30 mm are mounted vertically in terms of self-assembly or dowels.

3. With the outer sheel of the walls between the bars, if necessary, the thermal insulation material is laid.

4. Over the thermal insulation, another layer of waterproofing is stacked. Fasteners are produced by aluminum scotch tape or in any other way.

5. Faiths are attached to the simulation boards of timber. Start from the bottom, leveling horizontally over the level of the first board. Putting the boards is needed strictly thoroughly up so that in the grooves there is no moisture accumulation. Between the boards, it is necessary to leave the gap of 1-3 mm so that the finished surface under the action of external factors is not swamped.

Methods of fastening board

How to fix timber imitation Each specialist solves independently, based on its own skills and experience. There are several fasteners:

- nail or self-tapping screws in the spike at an angle of 45 degrees;

- Screwing is made in the front of the board;

- Nails are clogged into the groove;

- Special attachments are applied for installation - kleimers.

Imitation of timber - practical, inexpensive and beautiful finishing material, the use of which will make your home cozy, original, comfortable and warm.