Overlapping the roof with your own hands Construction

Professional flooring is a universal and relatively inexpensive material that has excellent corrosion resistance, good strength characteristics, and is widely used for many types of construction, installation and finishing works. Profiled sheets made of galvanized iron are manufactured, and thanks to their embedded, they acquire the necessary rigidity. The corrugalist is so also called professional flooring, perfectly established itself as a non-coordinate formwork for reinforced concrete structures, and as the siding of economic buildings and private houses, but in most cases it is used as a roof covering.

Content

Professional flooring - Reliable material for roofing

Frequently often builders make the roof overlap of the roof of the corrugation, since with the help of this material you can make an inexpensive, but very reliable roof. To do this, use both sheets without coating and with a polymer protective layer applied, which enhances corrosion resistance, and also carries aesthetic function. The roof looks much better when it has a colored coating, and the mirror plane is not blinded in the sun. Proflists are several primary colors: red, green, blue and brown. Which one to choose is a matter of taste, the quality of the sheets does not change from the color execution.

Anyone who has even minimal knowledge about construction and finishing work can use the hammer, scissors for metal, screwdriver and hacksaw, can independently cover the roof of the roof in the country. Before starting work on covering the roof, it is measured by its total area and skate length. The highest quality roof will be in the case when the length of the sheet of professional flooring will be equal to the length of the roof of the roof, then moisture in the horizontal joints completely exclude, which significantly increases the protective properties of the roof. After measurements and calculations, the required number of professional flooring and necessary for the work of additional accessories, such as self-tapping screws, skate bar, etc.

Prepare the surface for the floor

In order to qualitatively overlapping the roof of the roof with their own hands, it is necessary to carefully prepare the covered surface:

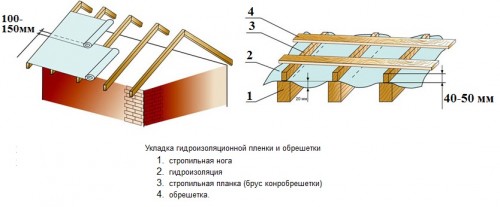

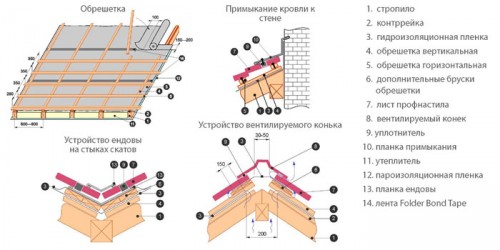

1. On the finished rafter design, a waterproofing membrane is fixed. It is necessary to prevent condensate accumulation during temperature drops on the lower part of the roofing, as well as between the roof and the attic space. If the roof design has rtanda, then the waterproofing laying is necessary to start with rolling rolls along it from top to bottom along the entire length. The membrane is then fixed on rafters horizontally all over the entire area of \u200b\u200bthe roof, not allowing the provispical material, from the eaves and to the skate, performing an overlap of the upper layer to the lower one. The use of vapor and waterproofing when covering the roof of a professional flooring, the cost somewhat increases, but it significantly extends the life of the entire roof.

2. After the vaporizolation is fixed throughout the surface of each of the skates, the installation of the root. First on the upper face of the rafted, along the entire length, a controlled tower is stuffed, which is a bar of 50x50mm. Its function includes fixation on steam barrier and creation of the base for the root. After that, the cheek itself is stuffed. For it, a board with a thickness of 30-35 mm and 100-150mm width. The boards are nailed to the counterclaim horizontally, strictly parallel to the roof ridge every 350 - 450 mm, depending on the decomposition of the roof plane. At the skate, for greater strength, each slot is nailed over the extra board. After the roof is fixed throughout the plane of the roof, we begin to overlap the roof of the roof of the corrugation according to the scheme.

Styling profile iron

If the length of the professionalists is equal to the length of the skate, they fit vertically, strictly parallel to the ridge of the roof. In this case, if the laying is performed on the right left, each next row is placed on top of the previous one, if on the contrary, it is led by it. This is due to the technology of giving the galvanized sheets of a certain relief. If the sheets are less, then the laying begins on the eaves, and the upper sheets are stacked with the overlap 5-15 cm, depending on the slope. To better understand the sequence of work Watch the video overlooking the roof of the roof of the roof:

The profile of the professional flooring is attached to special roofing self-strokes that have a rubber gasket. It is very important to choose the right moment of tightening the self-pressing, so as not to drag and not damage the gum, but also not to leave the professional official for the foundation. At the end, a metal skate bar is installed. It is attached by special skate screws with a frequency of 25 -30 cm, depending on the size of the profile wave.

conclusions

Summing up, you can draw the following conclusions. The use of professional flooring as roofing material is fully justified with many points of view. First, it is simplicity of installation. Secondly, the price of overlapping the roof of the roof is significantly less than when using other roofing materials. And the latter - the holding of these works is completely under the power of even one home master, without helpers.