Print technology on ceramic tiles Tile

Ceramic tiles as a finishing material today, perhaps, no one will surprise. The market offers a wide range of this product for every taste and different costs. Therefore, in conditions of such a tough competition, manufacturers in order to attract even more buyers try to diversify their products using new technologies in its production. One of these innovations of recent years can be considered a ceramic tile with photo printing.

Content

Ceramic tile with photo printing, advantages and scope of application

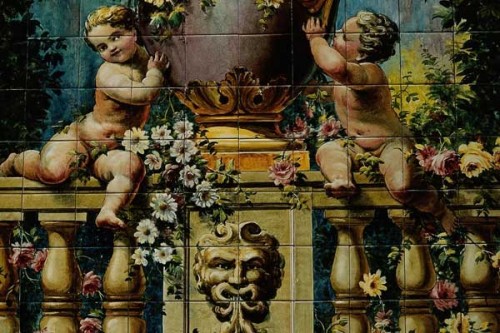

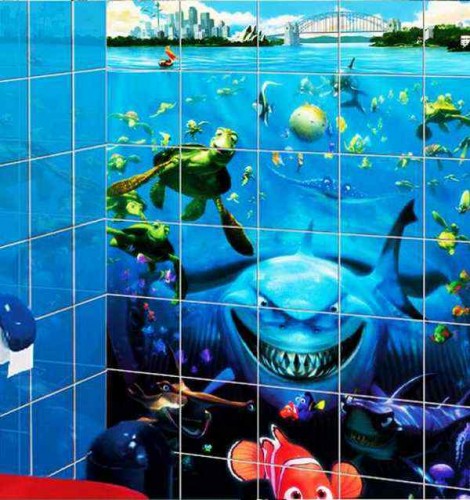

This finishing material quickly gained popularity due to the wide opportunities that it is able to give in the field of interior design. With the help of a photo printing tile, you can decorate any space, to realize the brightest and original ideas of the decor of the premises. Unusually beautiful tiled panels will inspire any connoisseur of the beautiful. At the same time, the tile with photo printing is quite practical and unpretentious in caring material. It is not afraid of temperature and humidity drops, scratches and other mechanical impacts, with the exception of abrasive detergents or substances on an alcohol basis.

Images on the photo shock are characterized by special brightness and perfect clarity. It can be separate drawings inserts or whole panels, 3D pictures or even portraits. The scope of such a finishing material is very large: it can be used to decorate the bathroom, kitchen, hallway, living room, pool in a private house, as well as in office space, cafes, restaurants, beauty salons, shops, medical and educational institutions, etc. .

Ceramic tile with photo printing can be of various sizes and shapes, and also have any drawing that can be applied to a different way. Consider the main technologies for applying a photographing to ceramic tiles.

Indirect technology drawing on ceramic tiles

Sublimated printing method on ceramics

This technology involves the use of a printer with special sublimation paints, with which the image in the mirror reflection is not printed on the tile, but on the paper specifically designed for these purposes. Then the sheet of this paper is applied to the tile and together with it under the press at a temperature of up to 180 degrees Celsius. The process of transferring an image or sublimation lasts only 3 minutes, after which the finished tile is lowered into cold water, and then coated with a layer of transparent glaze to secure the result and protection against any mechanical damage. In this way, you can apply any image as on the entire surface of the tile and on the individual parts of it.

An important condition for the application of this photo printing technology is the special requirements for the pottery itself, which should have the ability to withstand a large pressure. In addition, manufacturers, despite the resistance of such a finishing material to any external factors, do not recommend using abrasive detergents. Sublimation printing on ceramic tiles is often used because of the simplicity of the technology itself and the available cost of finished products.

More detailed process of sublimation printing can be viewed on video.

Method of hot decole

Such a printing technology on the ceramic tiles has similarities with the previous one that the picture or any image is not printed on the tile, but on the decol, which is applied to the tile and decolted with a decolch lacquer. The final stage is the firing of the finished tile in the muffle furnace at a temperature of up to 900 degrees Celsius.

The finished ceramic tile, created by the method of trimming of the decol, has such properties as a beautiful glass shine, durability, resistance to temperature differences and the negative effects of aggressive chemicals. Such tiles can be attributed to the elite class, since its cost is high enough.

Fingering method

Another, perhaps, the most reliable way to apply a picture to the surface of the ceramic tile, which involves the use of special ink and powder, on top of which the glaze is applied, and then the tile is sent to the baking furnace at a temperature of more than 800 degrees Celsius. As a result, the finished drawing becomes one whole with a tile, while has an attractive embossed surface. Such a photo complimentary is characterized by high strength and durability, as well as resistant to external influences, so it is more expensive than all kinds.

Curing method under ultraviolet rays

The safest method of production of photoseramics from the point of view of environmental protection. It is based on the use of special nanochernel, which under the action of ultraviolet rays almost instantly dried. The drawing is applied with a special ultraviolet printer over the glaze, in contrast to other methods. Thanks to this, paints are obtained brighter and rich. Thus, any drawing can be applied not only on ceramics, but also on other types of materials: glass, plastic, wood, etc. A photo shot, obtained using this method, has a limited service life of up to 10 years and in leaving requires the use of special detergents.

Direct printing on ceramic tiles

In addition to the above methods of applying a drawing on ceramic tiles, there is also a direct print method. This new technology for creating photographic and entire panels, which is based on the use of special printers, with which the digital image is printed on the tile, as on ordinary paper.

At the same time, unlike other technologies, there is no need for a subsequent roast of the finished product to secure the result. The resistance of the image is achieved due to the formation of a durable polymer layer on the surface of the tile and its warm-up in a conventional furnace for 10 minutes at a temperature of 150 degrees Celsius. The finished tile is distinguished by durability to various mechanical damage, has bright drawings that retain their original appearance not one dozen years.

New comments

Add a comment

To send a comment you need authorize.

who has experience? Share

About the last method is very interesting. I will search for equipment and all information!

There is a printer inexpensive + learning + ink set and primers.

How much will the printer cost?