Bath windows do it yourself Window

During the construction of a Russian bath, an important role is assigned to window designs. And this phenomenon is not accidental, because beautiful windows attach originality and aesthetics, and high-quality products serve as thermal insulation finish of the structure. Regardless of the material of manufacturing, design features and forms, windows are an indispensable attribute of the structure.

Content

The main characteristics of the windows for the bath

Starting the construction of the bath at the local area, it is necessary to clearly realize what functional responsibilities are assigned to the window structure. This will make it possible to choose or make the most suitable product, which will protect the structure from heat loss and give it exclusivity. Consider more detailed features that need to be observed:

- The window in the bathroom branch is recommended to mount a small size, as a rule, it is 600x800 mm. In this room there is no need to install bright lighting, and small dimensions of the product will allow you to save the heat in indoors.

- Do not mount constipation, cheeks or metal valves on the inside of the window. In this part of the bathroom, the moisture is strongly concentrated, and therefore the product will be subject to corrosion.

- Considering options for how to make a window in the bath, remember that the location of the construction depends on the preferences of the owner, and no regulations on this subject does not exist. For washing room window is usually mounted at head level, and in the steam room it is placed near the top shelf. However, experts recommend installing window as low as possible, as it eliminates the risk of heat loss.

- If the steam room is supplied with electricity, so the window is not installed at all. However, this solution leads to psychological discomfort, because the room becomes visually closed and this factor does not allow a person to relax to the fullest. Therefore recommended to install a small window for decorative functions.

- Despite the designer window in the bath, which is decorated with a photo glossy magazines, paint the inside window surface is undesirable. It is much more efficient to impregnate them with a special antiseptic composition. It is also recommended to install the product with the highest possible amount of glass in the package, as this will protect the steam room of the penetration of cold air and loss of efficiency.

Plastic windows for a bath

Plastic windows in the bath - this is not the best option, besides, he is not very popular. The main disadvantage of this construction - low level of resistance to high temperature conditions. Therefore, plastic products with high quality fittings and corrosion resistance are often mounted in the common room or the locker room.

Double-glazed windows of this material have a number of positive aspects of the operation. Consider the detailed list advantages:

- durability of the material with thorough care;

- good sound insulation data;

- do not require regular painting;

- are not affected by insects;

- resistant to moisture and excess moisture.

among the main shortcomings installing windows in a bath of PVC can be identified as follows:

- when exposed to a high temperature plastic exudes toxic substance;

- window prevents the normal circulation of air inside the room than creating stuffiness and discomfort;

- under the influence of moisture and hot air, the product is deformed and loses its functional properties rather quickly.

Wooden windows in the steam room

The most practical and reliable in use today - Windows for bath Wooden superior to the cost of plastic counterparts, but entirely okupayuyuschie itself in operation.

Consider the main benefits installation of wooden windows in the bath:

- Wood products are resistant to high temperatures, and retain their appearance under the influence of hot steam for a long time;

- Such windows are completely safe for human health, since the material is environmentally friendly;

- maintainability is one of the weighty advantages of using a wooden product in the bath: they are easy to paint, clean the scratches, adjust the accessories;

- window structures made of natural wood are well harmonized with a common bath design, not standing out against the background of the concept;

Among shortcomings Installations of wooden windows in the bath can be allocated as follows:

- without processing with a special antiseptic composition, such a window is exposed to loading, eating insects, the appearance of mold;

- the cost of the product from wood exceeds the prices of windows from PVC.

Wooden window in the steam room with your own hands

If you decide to install a window made in a steam room made by working work, you must consider several important points:

- In order for the steam room to be no heat loss, the size of the windows in the bath should be as small as possible. At the same time, it is desirable that the product has a double or triple glass and was used in direct intended, and not in decorative purposes.

- The optimal layout of the window is at the level of human eye, if it takes a sedentary position. Consider also that the lower the product is located and the farther it is from the heater, the better the thermal insulation of the room itself.

- In order for the window to ensure good air microcirculation indoors, it is necessary to open it simultaneously with the doors, creating drafts.

Window design

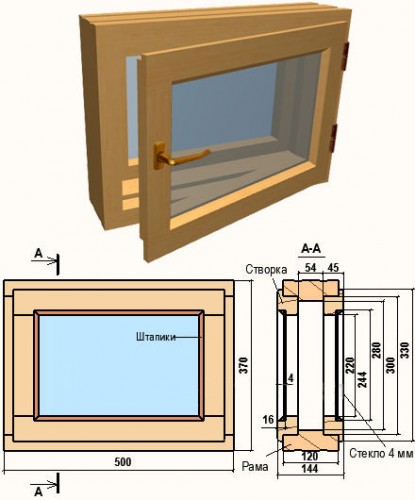

The most common window product is a standard structure from a rectangular outer frame, as well as two frames: outer and internal. Each of these sash has its own function, as they will ring the window inside the bath and outside.

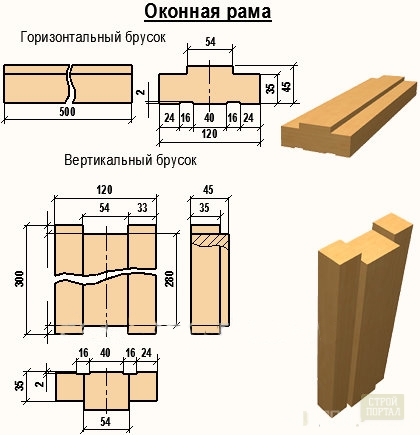

The window frame was made and profiled bars, which are fixed with each other with the help of the wood glue. It will allow you to connect items on the principle of "joint in the joint", and to give the stiffness of the entire structure, in the corners of the rails it is necessary to fix 2 screws.

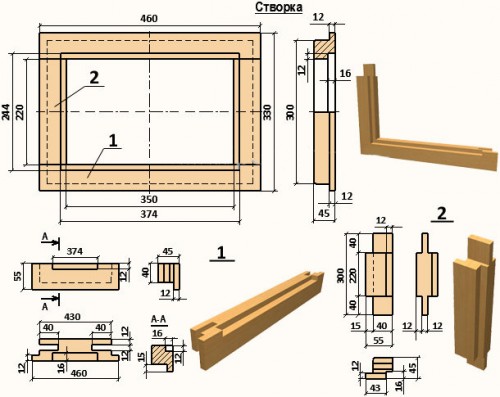

Installation of the window sash occurs on the principle of "spike in the groove", which implies the presence of protrusions on the vertical profile of the design and holes on the horizontal. The adjacent frame to the sash along the outer perimeter is ensured by the edge of 15-18 mm height, and in the inner - ends in the frame, which protrude by 10 mm. Each of the fragments is also fixed by means of special PVA glue.

Glazing occurs using a glass of 4 mm thick, which is mounted in the window sash grooves and is attached there with nails and a wooden stroke. This happens in the outside, and from the inside the circuit windows are treated with silicone sealant. In this case, each element of the window structure must be treated with an antiseptic composition of several layers, and the outer surface of the tree is preferably painted with acrylic paint.

Toolkit for the manufacture of the window

The construction window for a bathroom is the case, however, you will need to prepare the following tools:

- circulating machine or circular saw;

- manual milling and cutter;

- electric choke;

- screwdriver;

- wooden hacksaw;

- level;

- chisels;

- rasp;

- kiyanka;

- hammer;

- roulette;

- sandpaper;

- corolnic

Materials for the manufacture of the window

The best material for the construction of the window in the steam room has always been natural wood. The internal structure of operational characteristics and appearance are optimally suitable for windows that need to be mounted in rooms with high humidity and temperature.

Best tree for window design - oak. But if it was not possible to find it, other breeds of wood type, for example, birch or linden are allowed. However, it is worthwhile to avoid the manufacture of windows of coniferous varieties of wood - ate erected pines, since they are isolated by a resin at a temperature effect, and this creates discomfort for a person.

So, for the construction process you will need:

- Strokes 10 mm high;

- glass with a thickness of 4 mm;

- cutting board 125x50 mm for frame;

- Wooden bar 60x50mm for sash;

- For one sash: Rotary handles - 1 pc., loops - 2 pcs.;

- Self-tapping screws - 8 pcs. For frame and 4 pcs. for each sash;

- PVA glue for wood.

Window Manufacturing Guide

- The initial stage is cutting all the necessary blanks with batteries for pure work. For details of the same type, for example, brucks of the window sash, the workpiece must be common. It should be processed initially, and then cut into fragments of the desired length.

- Cut out the blank on the chisty dimensions: for the window sash - 55x45 mm, and for the frame - 120x45 mm.

- Cut fragments of the desired length.

- We proceed to the rough processing of spikes and grooves with a manual milling tool. If you use a circular machine, then they can make longitudinal grooves that are cut horizontally and vertically at an angle of 90˚. When working, do not forget to leave points.

- We begin to finish the proceedings using the hand mill for this. The work is made on the principle of overall tool based in relation to the workpiece. In other words, if the groove is molded under the glass, then it must be done alternately for all billets, without changing the cutter.

- We proceed to the test assembly of the frame and window sash, during which you can identify the correctness of the joints of all compounds and finally adjust each fragment of the design.

- If the preliminary assembly was successful, it is possible to start gluing the parts of the PVA glue. In this process, it is important to gut all the frames, sash, angles. Press the glued elements is best self-drawing or clamps.

- We install the handles, mount the loop and proceed to the glazing design.

- Window ready to use.

Important! If there are no special woodworking tools in the presence, then it is quite problematic to ensure a dense fit of the windows. Therefore, it is initially recommended to make sash, then remove the actual dimensions of the elements that are conjugated with the frame and already on these data cut the frame. It will be the least laborious process, since the configuration of the window frame is much easier.

Detailed window manufacturing instructions in the steam room are presented on video: