Facing the bass furnaces do it yourself Baths, saunas and pools

The fireplace or oven, built in a house or bath, often serve not only means of obtaining heat, but also play an important role in creating an original interior. Therefore, their appearance, in particular, the facing is paid to special attention. Materials that can be made by facing furnaces and fireplaces, there is a lot of which one to apply - depends on the fancy of the wizard, style in which the room is decorated, the availability of agents.

Content

What facing materials are customary to use when refining fireplaces and stoves

As finishing materials for furnaces and fireplaces can be used:

- tiemas

- stone

- ceramic tile

- brick.

Interesting design can be obtained when using plaster. If the fireplace or oven is built of high-quality bricks, then you can do without finishing: laying seams gently drag and expand. The color of the brick can be left natural or change to any other, if desired. To do this, it will only be necessary to apply a layer of high-quality heat-resistant paint.

Often experienced masters use a combination of several finishing materials.

The easiest way of cladding is plastering

You can apply plaster only making sure the brick masonry drying. Preparation of the surface K.walking Make as usual:

- clean the dust from it, all the contamination, the residues of the solution;

- clean the seams at a depth of approximately 1 cm;

- before starting work, the furnace is soapped;

- on the surface, the metal grid is mounted, it is fixed using wire;

- next, the surface is moisturized, the first layer of liquid plaster is applied;

- after hardening this layer, it is proceeded to apply the second, the solution for it is done more thick, pasty.

In total, the thickness of the layers should not exceed 5 mm. It is necessary to apply a solution to a trowel, it is possible to dissolve it with a spatula, zigzag movements. Properly applied plaster will fall smoothly, without aircraft and strips. After drying, the applied layer is treated with a grater, to obtain an ideally smooth surface.

In addition to decorative significance, the application of the plaster layer will serve as a factor in improving fire safety. The mortar for plaster is made on the basis of clay to make it a stronger addition salt.

As an element of the decor, the rustache is made on the plastered surface, it is to apply to the surface of the shallow grooves-contours of the drawing and subsequent staining: the main canvas in one shade, the grooves in the other.

After removing the dust from the surface and processing it, it is possible to start applying paint or bliss. Considering how the facing of the furnace looks like in the photo, it can be noted that the paint is customary to use natural shades: Ohru, Surik, ultramarine,blanophiks.

You can prepare adhesive paint yourself, the basis for it will serve lime milk. Salt, glue, dye, stirred and filtered into the solution. To reflect metal doors topial and solnikused silicone paints.

Facing stone stoves

Stone is an amazing facing material that is used for many centuries. His durability,ecologyResistance to moisture and temperatures allows the use of a bath, its rich color gamut and a variety of textures and surface options attract attention to a noble and original view.

It is not possible to use all the material as a finishing stone for a bath, mostly manufacturers of metal bath furnaces use:

- coil;

- marble;

- talco chlorite;

- jade.

These natural stones are very durable, can withstand an infinite amount. heating Up to high temperatures, they accumulate heat, then for a long period exuded it from its surface, maintaining the room temperature. Natural stones are not afraid of the effects of the acid or alkaline medium.

Besides:

- talco Chlorite can be used as a filling for a stove-heater,

- the coil extracted in the Urals possesses therapeutic properties, it normalizes blood pressure, stimulates blood circulation, normalizes metabolic processes in the body

- jadeitis has antimicrobial properties andmineralizet Water contributes to curable skin diseases and pulmonary.

It is not inferior to naturally created by beauty and strength artificially created stones, a furnace or fireplace, the cladding of which is made by artificial stone, allow you to complicate the interior, make it more original.

The technology of finishing the stone is not complicated, but will require special preparatory work. A lot of time and patience will require a fitting fit - after all, they have a non-standard form and before mounting on the wall they will have to be decomposed on the floor. Selected stones are marked and further, according to labeling, fasten with the help of an adhesive solution to the surface, just like ceramic tiles.

Classic Facing Option - Ceramic Tile

This type of finish refers to more complex and requires certain skills from the artist. Facing the furnaces can be performed by any tile, but it is possible to prefer refractory material. You can accelerate the work by using large-sized tiles, but if the size of the furnace or the fireplace is minor, and the design intention is sensitive, then it usually arises difficulties with the tile fit.

Experts believe that it is better to choose the lowest extension coefficient and characterized by a dense structure to finish hot surfaces and distinguished by dense structures.

The initial preparation of the surface is important: it is required to be cleaned of paint residues or blots, dust. On the surface of the fireplace or the furnace, the grid is mounted using glue, it is used to align the wall. The direction of laying is determined by the help of a plumb and level, beton it with a cord.

Work starts from the bottom row. It is important to immediately notice all the defects of the masonry and correct them, after soaring the glue will not be able to do it. Excess glue should be removed immediately, to produce seams after drying it.

Tiles - finishing tiles handmade

Facing the furnace can be performed by tiles - a special type of tile made manually. The main difference of tiles is the presence on the wrong siderMSPrepresenting a similar container education. With helprMSP Produce tile fastening.

Tiles have several varieties:

- glazed and relief;

- smooth and majolica.

For the manufacture of any of the types, pottery plastic clay is used, to give material strength, the blanks are subjected to burning at temperatures above 1000 degrees.

The furnace, the facing of which is made of the tiles very beautiful, it is easy to clean from any contamination. Facing with tiles allows you to block the seams of brick masonry, which warns the penetration of smoke into the bathroom.

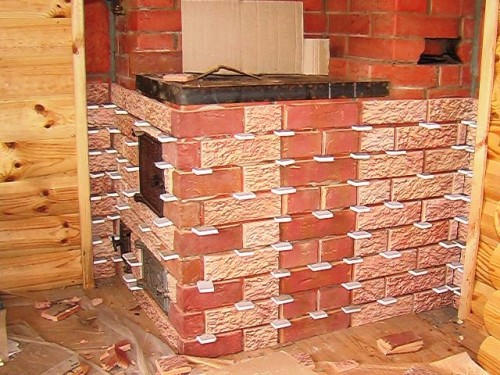

Facing a stove brick

A brick can be used to find a bath furnace, of course, the best quality is usually called clinker. This is the easiest performed and cheap finishing method, it can be performed with your own hands.

The work consists in building an additional, facing layer of masonry. To give greater decorativeness, combine bricks of different color, use a contrasting shade of grout, the masonry itself is performed by rows or christmas.